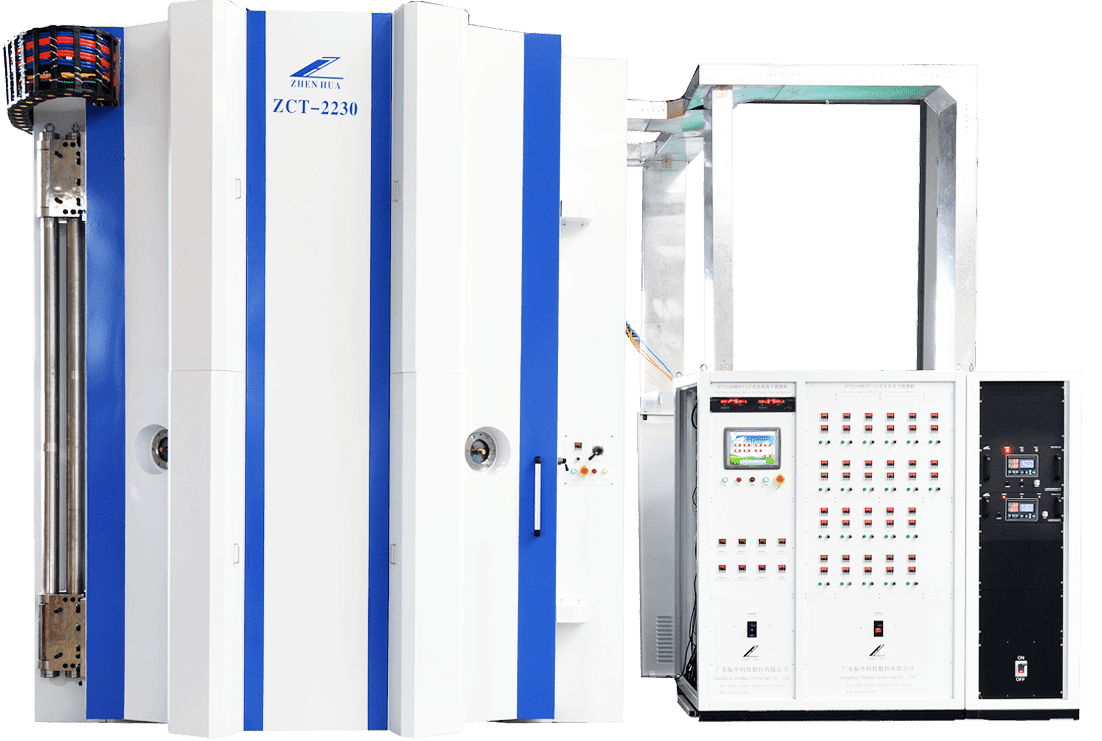

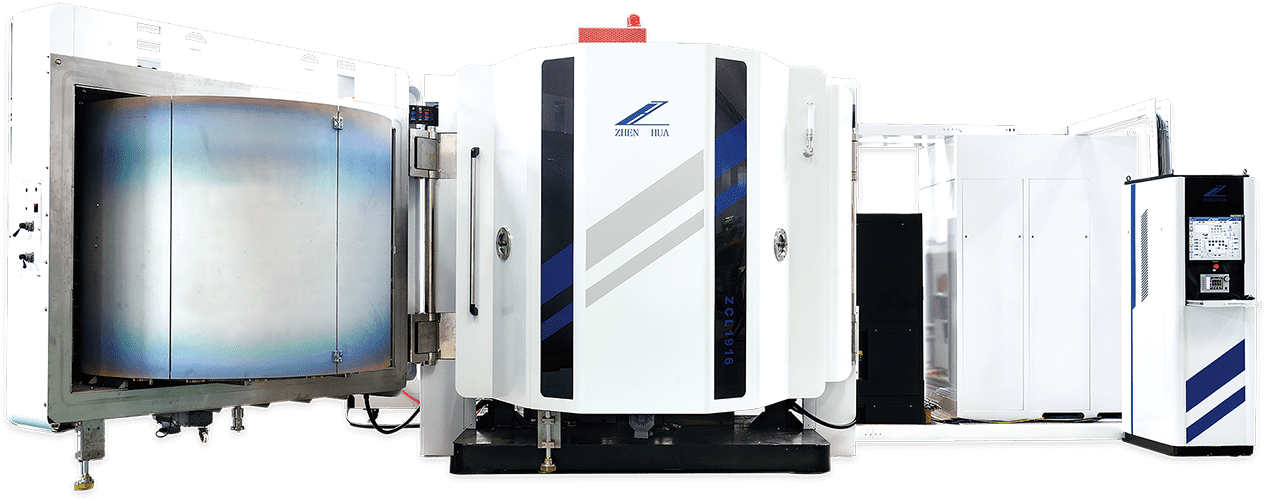

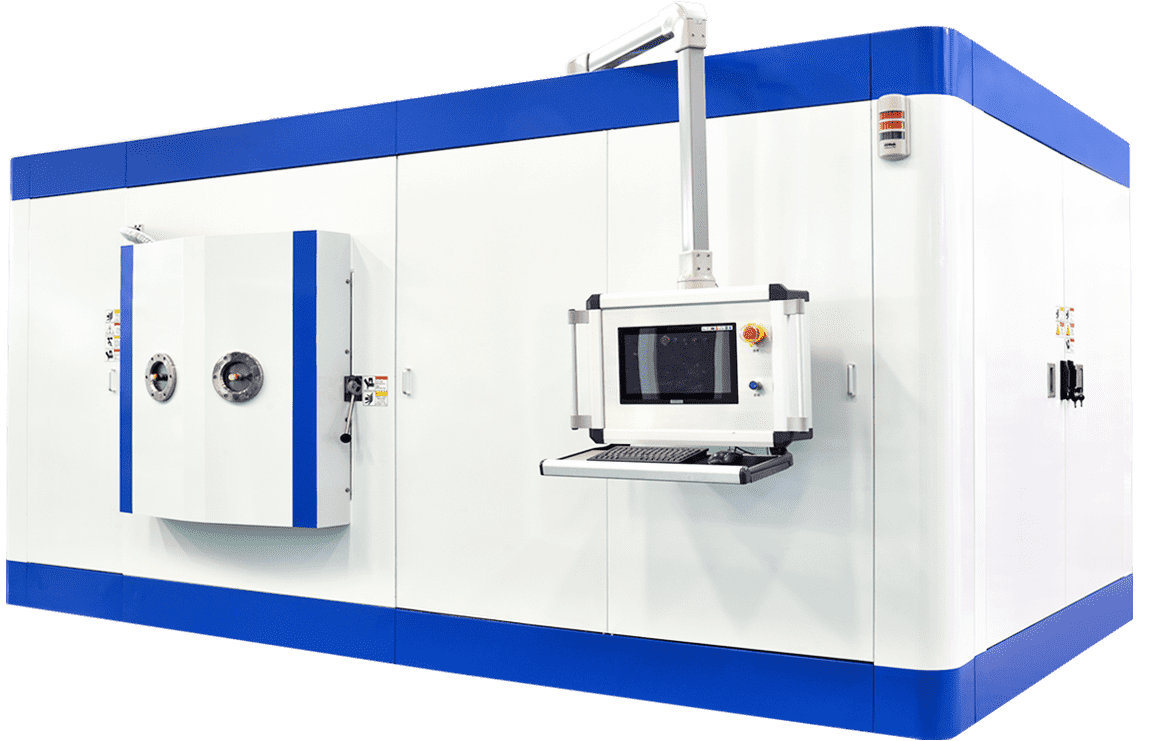

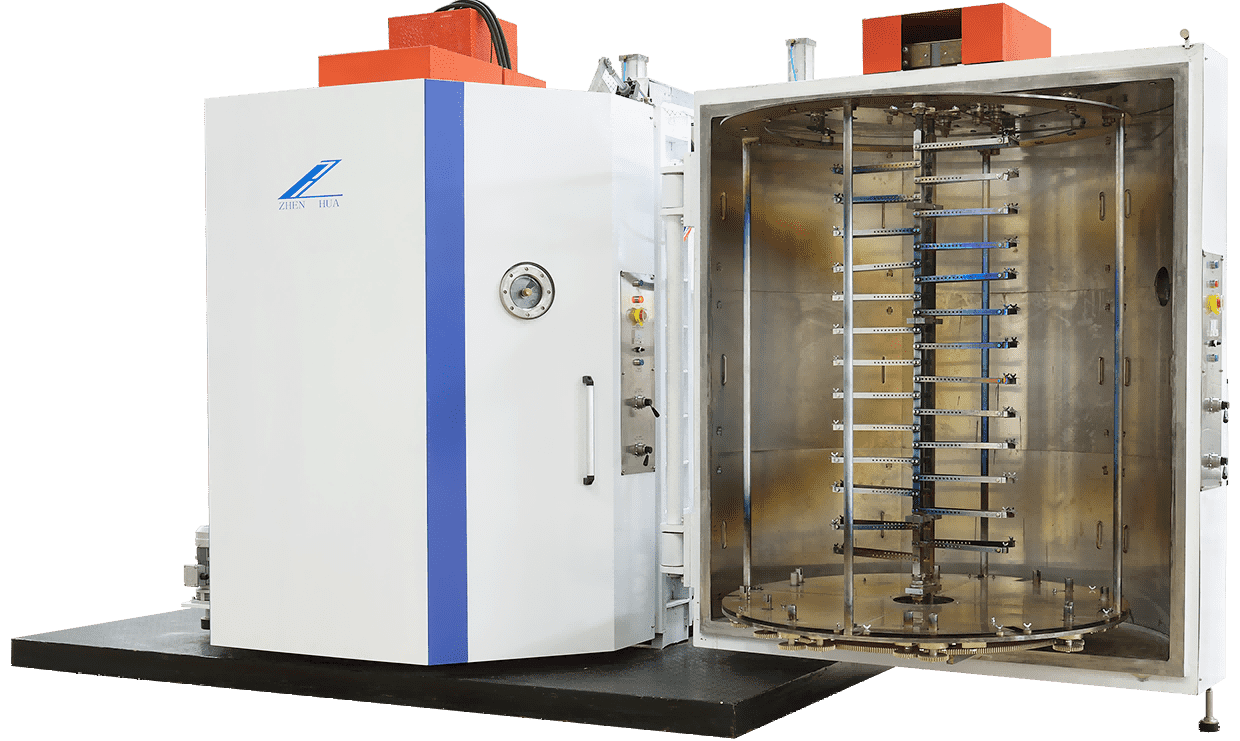

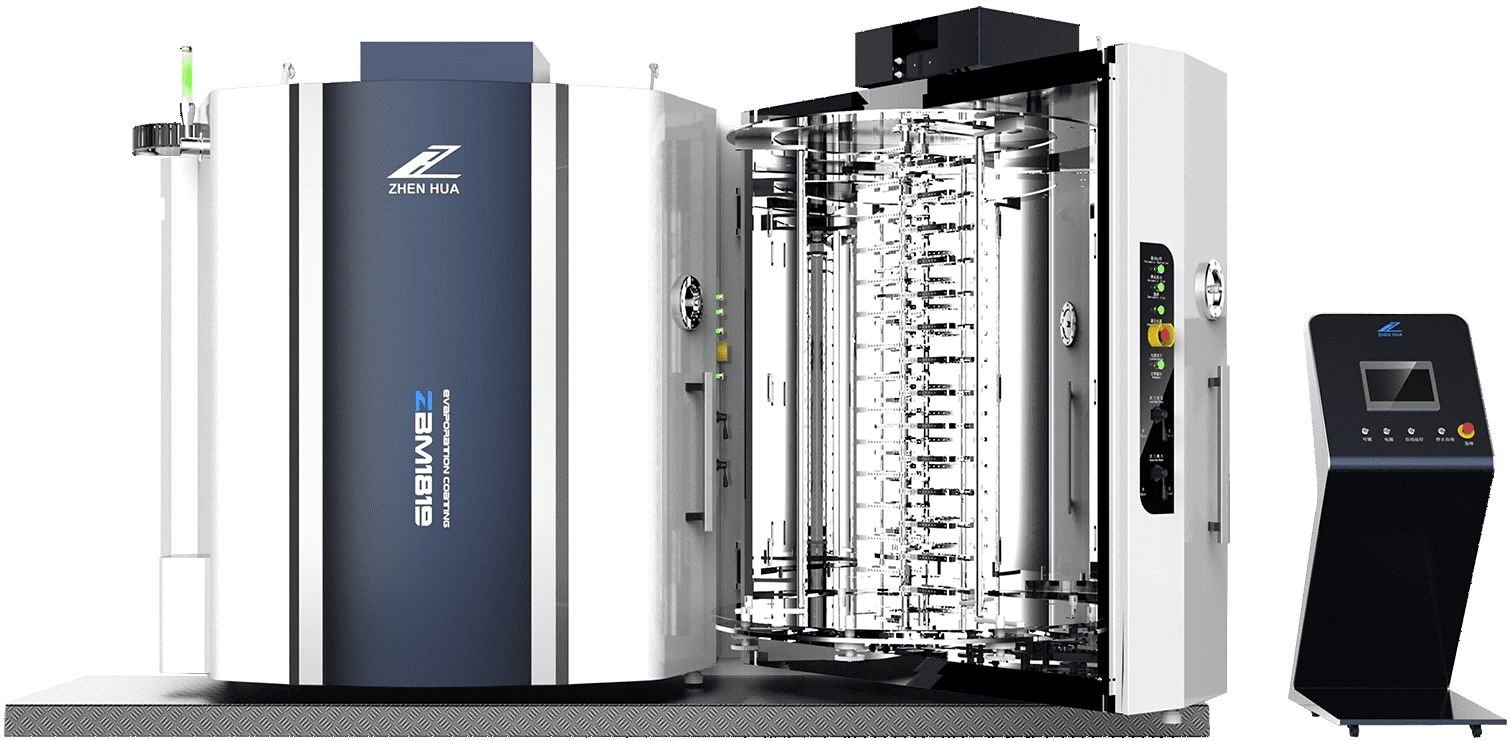

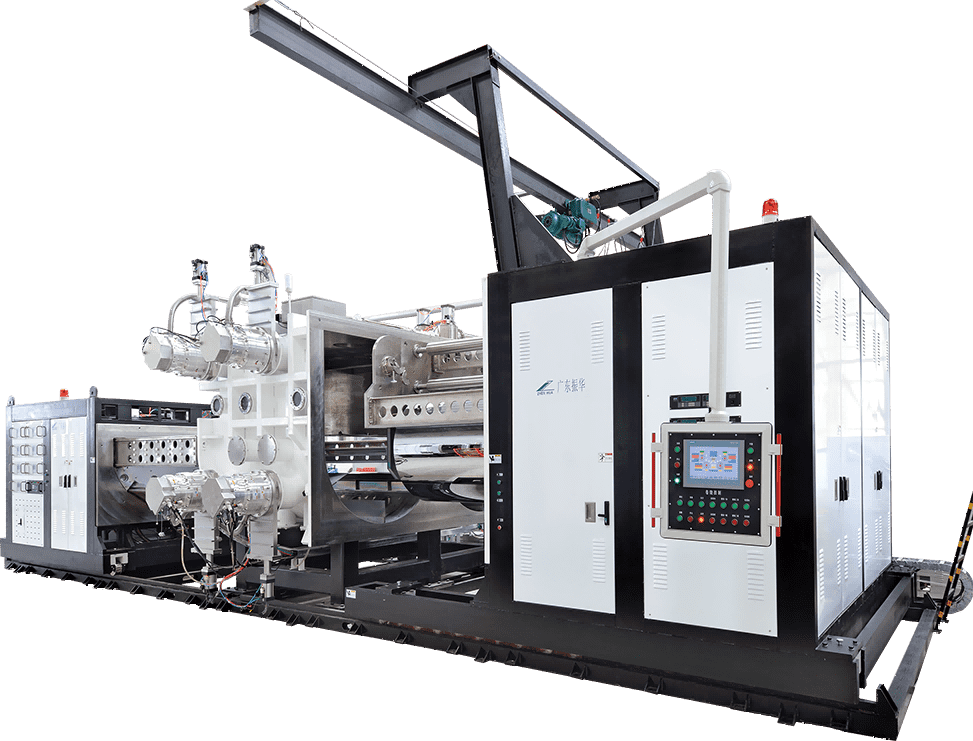

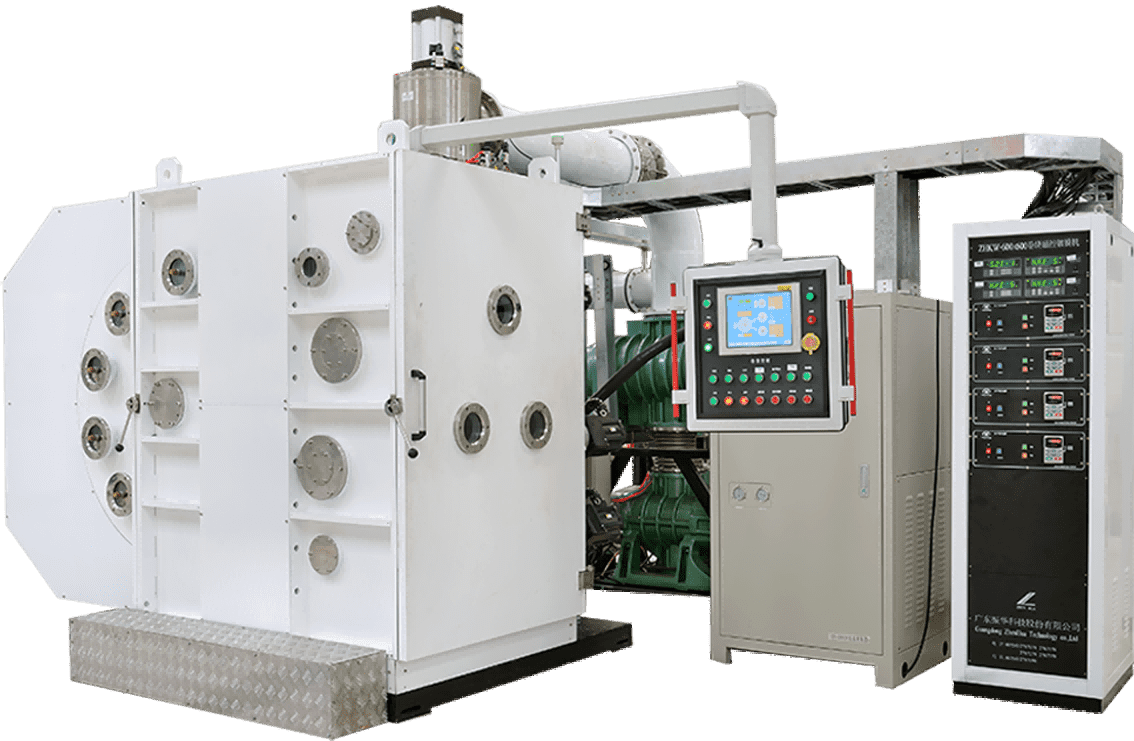

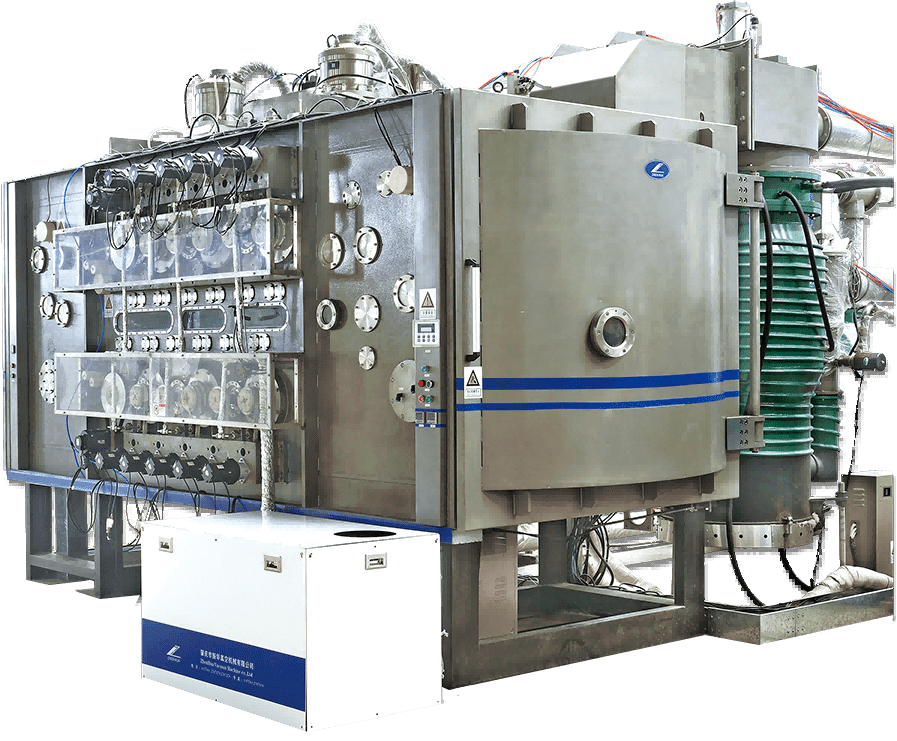

Guangdong Zhenhua Technology Co., Ltd. (formerly known as Zhaoqing Zhenhua Vacuum Machinery Co., Ltd.) was established in 1992, is an enterprise specializing in providing customers with high quality vacuum coating solutions, independently developing, producing and selling vacuum coating equipment, providing coating technology and technical support. The company’s headquarter is located in Zhaoqing City, Guangdong Province, and has three production bases in Zhaoqing City, respectively Yungui Zhenhua Industrial Park, Beiling Production Base and Lantang Production Base; at the same time, it has a number of sales and service centers, such as Guangdong Zhenhua Technology Co., LTD.

Click View