ወደ Guangdong Zhenhua Technology Co., Ltd እንኳን በደህና መጡ።

የኢንዱስትሪ ዜና

-

የመቁረጫ መሣሪያ ሽፋን-ምዕራፍ 1 ሚና

የመቁረጫ መሳሪያ ሽፋኖች ግጭትን ያሻሽላሉ እና የመቁረጫ መሳሪያዎችን ይለብሳሉ, ለዚህም ነው በመቁረጥ ስራዎች ውስጥ አስፈላጊ የሆኑት. ለብዙ አመታት የገጽታ ማቀነባበሪያ ቴክኖሎጂ አቅራቢዎች የመቁረጫ መሳሪያ የመልበስ መቋቋምን ለማሻሻል ብጁ የሽፋን መፍትሄዎችን ሲያዘጋጁ ቆይተዋል፣ የማሽን ኢፊ...ተጨማሪ ያንብቡ -

በቫኩም ሲስተም ውስጥ የተለያዩ የቫኩም ፓምፖች መግቢያ

የተለያዩ የቫኩም ፓምፖች አፈፃፀም ወደ ክፍሉ ውስጥ ቫክዩም ከማስገባት ችሎታ በተጨማሪ ሌሎች ልዩነቶች አሏቸው። ስለዚህ በሚመርጡበት ጊዜ በፓምፑ የተከናወነውን ሥራ በቫኩም ሲስተም ውስጥ ግልጽ ማድረግ በጣም አስፈላጊ ነው, እና ፓምፑ በተለያዩ የስራ መስኮች ውስጥ የሚጫወተው ሚና ተጠቃሏል ...ተጨማሪ ያንብቡ -

የሴራሚክ ወለል ንጣፎች የሚረጭ የቫኩም ሽፋን ማሽን

የሚረጭ የቫኩም ሽፋን ማሽን ቀጭን የፊልም ሽፋኖችን በሴራሚክ ወለል ላይ ለመተግበር የላቀ ቴክኖሎጂን ይጠቀማል። ይህ ሂደት የብረት ወይም የተደባለቁ ሽፋኖችን በንጣፎች ላይ ለማስቀመጥ የቫኩም ክፍልን መጠቀምን ያካትታል ይህም ዘላቂ እና የሚያምር አጨራረስ ያስገኛል...ተጨማሪ ያንብቡ -

የመኪና ክፍሎች ሜታልሊዚንግ የቫኩም ሽፋን ማሽን

ይህንን አዝማሚያ ከሚያራምዱት ቁልፍ ምክንያቶች መካከል ከፍተኛ ጥራት ያለው ሽፋን በአውቶማቲክ ክፍሎች ላይ የመጠቀም አስፈላጊነት ግንዛቤ እያደገ መምጣቱ ነው። እነዚህ ሽፋኖች የክፍሎቹን ውበት ከማሳደጉም በላይ ከዝገት እና ከመልበስ መከላከያ ይሰጣሉ፣ በመጨረሻም የመኪናውን የህይወት ዘመን ያራዝማሉ።ተጨማሪ ያንብቡ -

የመስታወት ሴራሚክ ንጣፎች የወርቅ ንጣፍ ማሽን

የብርጭቆው የሴራሚክ ሰድላ የወርቅ ፕላስቲንግ ማሽኑ በቀጭኑ የወርቅ ንጣፍ ንጣፍ ንጣፍ ላይ በመተግበር የላቁ ቴክኒኮችን ይጠቀማል፣ ይህም አስደናቂ እና የቅንጦት ገጽታ ይፈጥራል። ይህ ሂደት የንጣፎችን ውበት ከማሳደጉም በላይ ተጨማሪ ጥበቃን ይሰጣል ...ተጨማሪ ያንብቡ -

የንጥረ ነገሮች እና የፊልም ምርጫ መርሆዎች

በፊልም ዝግጅት ሂደት ውስጥ, ንጣፉ በሚከተለው የኃይል ወለል መሰረት ሊመረጥ ይችላል: 1. በተለያዩ የትግበራ ዓላማዎች መሰረት, የወርቅ ሾው ወይም ቅይጥ, ብርጭቆ, ሴራሚክስ እና ፕላስቲክ እንደ ንጣፍ ይምረጡ; 2. የንጥረ ነገሮች አወቃቀሩ ከፋይ ጋር ይዛመዳል ...ተጨማሪ ያንብቡ -

በፊልሙ ላይ ያለው የከርሰ ምድር ወለል ቅርጽ እና የሙቀት መስፋፋት Coefficient

የፊልም እድገትን መጋፈጥ በጣም ጠቃሚ ተጽእኖ አለው. የንጥረቱ ወለል ትልቅ ከሆነ ፣ እና የበለጠ እና የበለጠ ከወለል ጉድለቶች ጋር ከተጣመረ ፣ የፊልም አባሪ እና የእድገት መጠን ላይ ተጽዕኖ ያሳድራል። ስለዚህ, የቫኩም ሽፋን ከመጀመሩ በፊት, ንጣፉ ቅድመ-ሂደት ይሆናል ...ተጨማሪ ያንብቡ -

የመቋቋም ማሞቂያ የትነት ምንጭ ባህሪያት, መስፈርቶች እና የቁሳቁስ ምርጫ

የመቋቋም ማሞቂያ ትነት ምንጭ መዋቅር ቀላል, ለመጠቀም ቀላል, ለመሥራት ቀላል ነው, በብዛት ጥቅም ላይ የዋለው አንድ ዓይነት የትነት ምንጭ ነው. ሰዎች ብዙውን ጊዜ የሙቀት ማመንጫ ወይም የትነት ጀልባ ይባላሉ። ጥቅም ላይ የዋለው የመከላከያ ቁሳቁስ መስፈርቶችን ማሞቅ-ከፍተኛ ሙቀት ፣ የመቋቋም ችሎታ ፣ ...ተጨማሪ ያንብቡ -

የትነት ምንጭ ንድፍ እና የችግሩ አጠቃቀም

በቫኪዩም ትነት እና በቫኩም ion ሂደት ውስጥ የሜምፕል ማቴሪያሉ በ 1000 ~ 2000C ከፍተኛ ሙቀት ውስጥ ስለሚሆን የትነት ምንጭ ተብሎ የሚጠራው የመሣሪያው Yanfa ትነት ነው። የትነት ምንጭ ብዙ ዓይነቶች፣ የነጭ ሽንኩርት ፀጉር ምንጭ የሜምፕል ቁሶች ትነት የተለያዩ ናቸው...ተጨማሪ ያንብቡ -

የፕላስቲክ ማንኪያ ፒቪዲ የቫኩም ሽፋን ማሽን

PVD (Physical Vapor Deposition) የቫኩም ሽፋን የቫኩም ክፍልን በመጠቀም ቀጫጭን ፊልሞችን በንዑስ ወለል ላይ ለማስቀመጥ የሚደረግ ሂደት ነው። ይህ ቴክኖሎጂ የተለያዩ ምርቶችን አፈጻጸም እና ገጽታ ለማሳደግ በማኑፋክቸሪንግ ውስጥ በስፋት ጥቅም ላይ የዋለ ሲሆን አሁን ደግሞ በምርቶቹ ላይ...ተጨማሪ ያንብቡ -

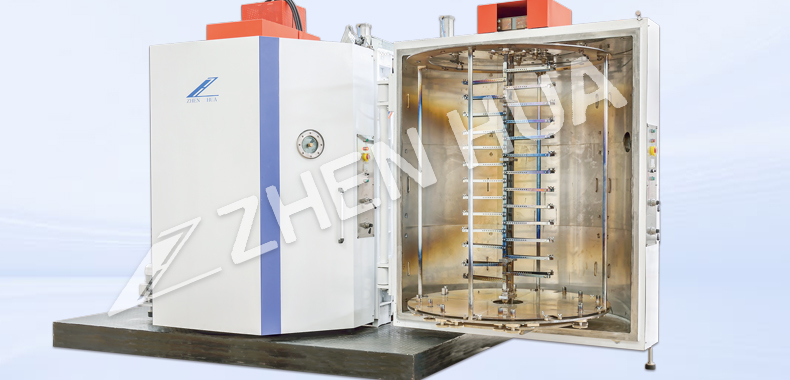

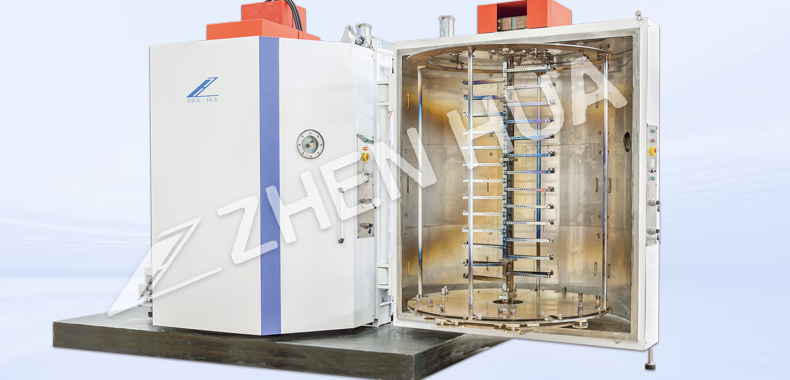

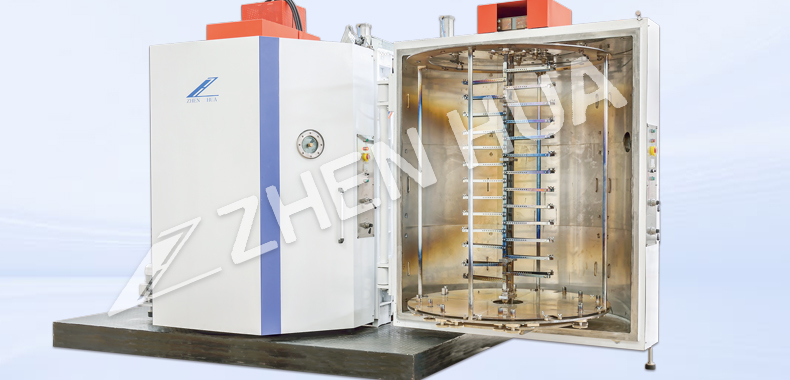

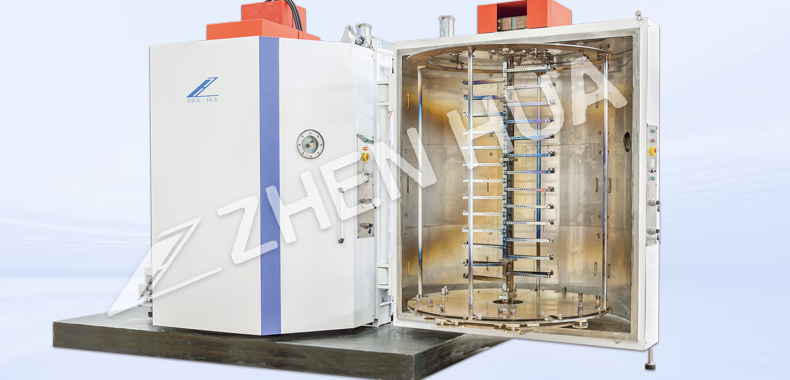

ሁለገብ የቫኩም ሽፋን መሳሪያዎች

ሁለገብ የቫኩም ማቀፊያ መሳሪያ ዘመናዊ ቴክኖሎጂን በመጠቀም ስስ ሽፋንን ለተለያዩ ቁሳቁሶች ማለትም ብረቶች፣ መስታወት እና ፕላስቲኮችን ይጠቀማል። ይህ ሂደት የምርቶቹን ውበት ብቻ ሳይሆን ጥንካሬያቸውን እና አፈፃፀማቸውን ያሻሽላል. በዚህም ምክንያት ማኑ...ተጨማሪ ያንብቡ -

የንፅህና እቃዎች ፒቪዲ የቫኩም ሽፋን መሳሪያዎች

የንፅህና መጠበቂያ ዕቃዎች PVD የቫኩም ሽፋን መሳሪያዎች የንፅህና መጠበቂያ ዕቃዎችን በማምረት ረገድ የጨዋታ ለውጥ ነው. ይህ የላቀ ቴክኖሎጂ በንፅህና መጠበቂያ ዕቃዎች ላይ ዘላቂ እና ረጅም ጊዜ የሚቆይ ሽፋን ለመፍጠር ፊዚካል ትነት ማስቀመጫ (PVD) የሚባል ሂደት ይጠቀማል። ውጤቱም ከፍተኛ ጥራት ያለው አጨራረስ ነው ...ተጨማሪ ያንብቡ -

ትክክለኛነት የቫኩም ሽፋን መሳሪያዎች

ትክክለኛ የቫኩም መሸፈኛ መሳሪያዎች ቀጭን ፊልሞችን እና ሽፋኖችን ለተለያዩ ቁሳቁሶች እጅግ በጣም ከፍተኛ ትክክለኛነት የሚተገበሩ ልዩ ማሽኖችን ያመለክታል. ሂደቱ የሚካሄደው በቫኪዩም አካባቢ ውስጥ ነው, ይህም ቆሻሻዎችን ያስወግዳል እና ከፍተኛ ተመሳሳይነት እና ወጥነት ባለው ሽፋን ላይ ያመጣል.ተጨማሪ ያንብቡ -

ትልቅ አግድም የቫኩም ሽፋን መሳሪያዎች

ከትልቅ አግድም የቫኩም መሸፈኛ መሳሪያዎች ቁልፍ ጥቅሞች አንዱ ቀጭን እና ተመሳሳይ ሽፋኖችን ለትላልቅ እና ጠፍጣፋ ንጣፎች የመተግበር ችሎታ ነው። ይህ በተለይ እንደ መስታወት ማምረቻ ባሉ ኢንዱስትሪዎች ውስጥ በጣም አስፈላጊ ነው ፣ በትልቅ ወለል ላይ ወጥ የሆነ የሸፈነ ውፍረት ማሳካት አስፈላጊ ነው…ተጨማሪ ያንብቡ -

Watch Ion Gold Vacuum Coating Machine

የሰዓት ion ወርቅ ቫክዩም ሽፋን ማሽን የስራ መርህ አካላዊ የእንፋሎት ማጠራቀሚያ (PVD) ሂደትን በመጠቀም በሰዓት ክፍሎች ላይ ቀጭን የወርቅ ንጣፍ ንጣፍ ማድረግ ነው። ሂደቱ ወርቁን በቫክዩም ቻምበር ውስጥ በማሞቅ እንዲተን በማድረግ ላይ ላዩን...ተጨማሪ ያንብቡ