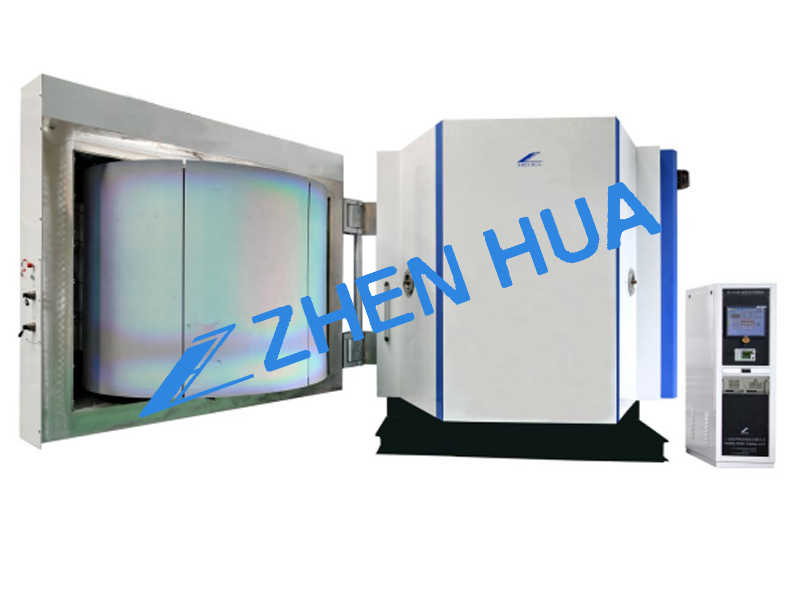

Sputtering coating machine to coat rainbow colors

Magnetron sputtering is a kind of physical vapor deposition. The general sputtering method can be used to coat metal, semiconductor, insulator and other materials, and has the characteristics of large loading capacity , easy to operation, the coating film is very fine and smooth, with good adhesion and so on. Magnetron sputtering can increase the sputtering rate by introducing a magnetic field on the cathode surface of the target and using the constraint of the magnetic field on the charged particles to increase the plasma density. A complete magnetron sputtering vacuum coating machine is composed of many parts, each system complete different functions, and finally achieve the final high-quality coating. The magnetron sputtering optical coating equipment is composed of vacuum chamber, valve, vacuum pumping system, vacuum measurement system, cathode target, film thickness gauge, electro-pneumatic control system, etc. The main body of the magnetron sputtering optical coater is vacuum chamber, the size is determined by the size of the product substrate and the capacity of the user. The chamber is made of SUS304 stainless steel, which is not easy to rust, more durable than carbon steel and easy to do maintenance. Machine adopted medium frequency sputtering coating technology, coating with oxide materials such as silicon oxide and niobium oxide etc, with film thickness gauge to make optical decorative film. The film made by magnetron sputtering optical coating machine has strong adhesion and high purity, and can be sputtered with a variety of materials with different components at the same time.

The process of gradual change color is generally made by magnetron sputtering optical coating machine. At present, the back cover of many mobile phones adopts PVD vacuum coating gradual change color process. Of course, optical coating machine and evaporation coating machine can also make similar rainbow seven color effect, but the colors are not regular gradients and there are still has differences in quality. Magnetron sputtering is a kind of physical vapor deposition. The general sputtering method can be used to coat metal, semiconductor, insulator and other materials, and has the characteristics of large loading capacity , easy to operation, the coating film is very fine and smooth, with good adhesion and so on.

Magnetron sputtering can increase the sputtering rate by introducing a magnetic field on the cathode surface of the target and using the constraint of the magnetic field on the charged particles to increase the plasma density. A complete magnetron sputtering vacuum coating machine is composed of many parts, each system complete different functions, and finally achieve the final high-quality coating. The magnetron sputtering optical coating equipment is composed of vacuum chamber, valve, vacuum pumping system, vacuum measurement system, cathode target, film thickness gauge, electro-pneumatic control system, etc.

The main body of the magnetron sputtering optical coater is vacuum chamber, the size is determined by the size of the product substrate and the capacity of the user. The chamber is made of SUS304 stainless steel, which is not easy to rust, more durable than carbon steel and easy to do maintenance. Machine adopted medium frequency sputtering coating technology, coating with oxide materials such as silicon oxide and niobium oxide etc, with film thickness gauge to make optical decorative film. The film made by magnetron sputtering optical coating machine has strong adhesion and high purity, and can be sputtered with a variety of materials with different components at the same time.