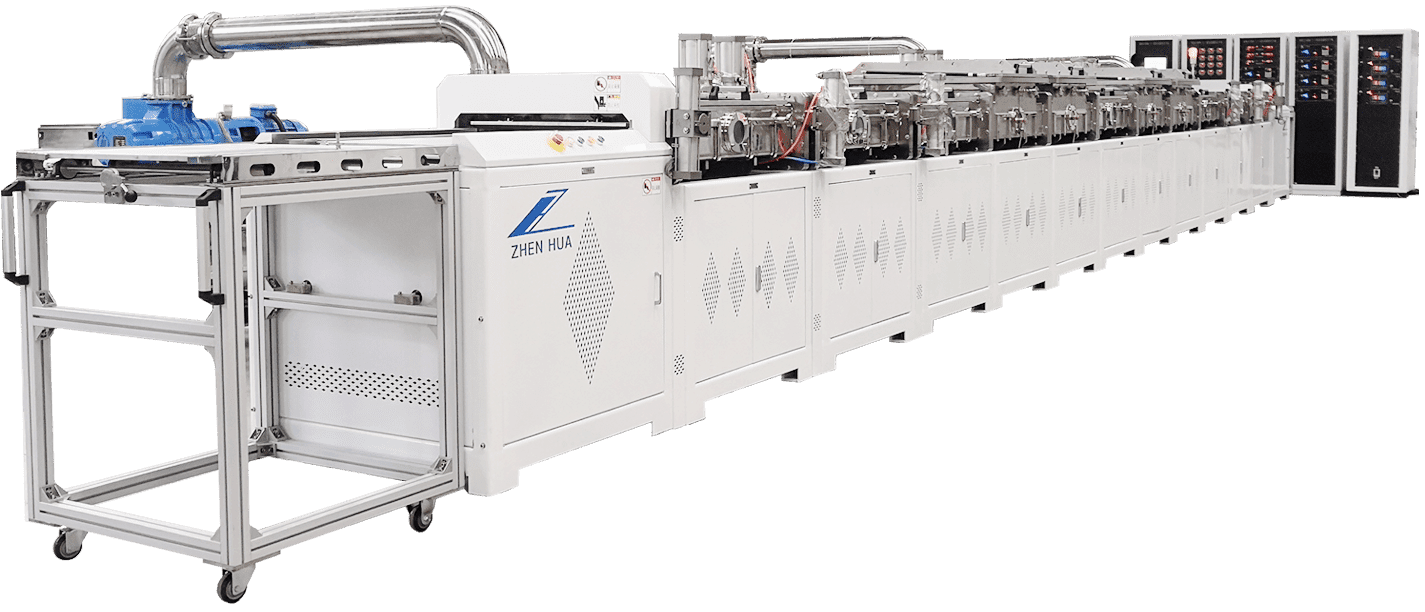

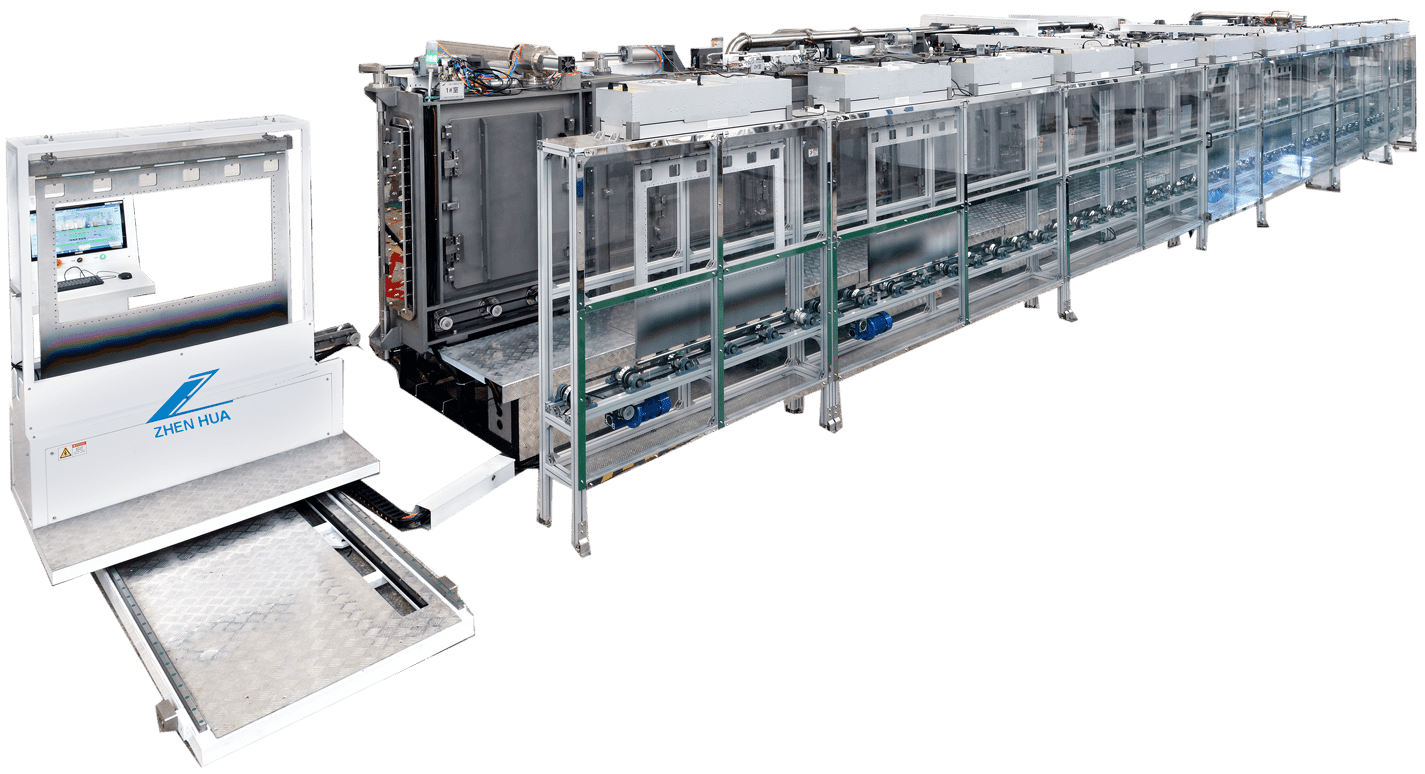

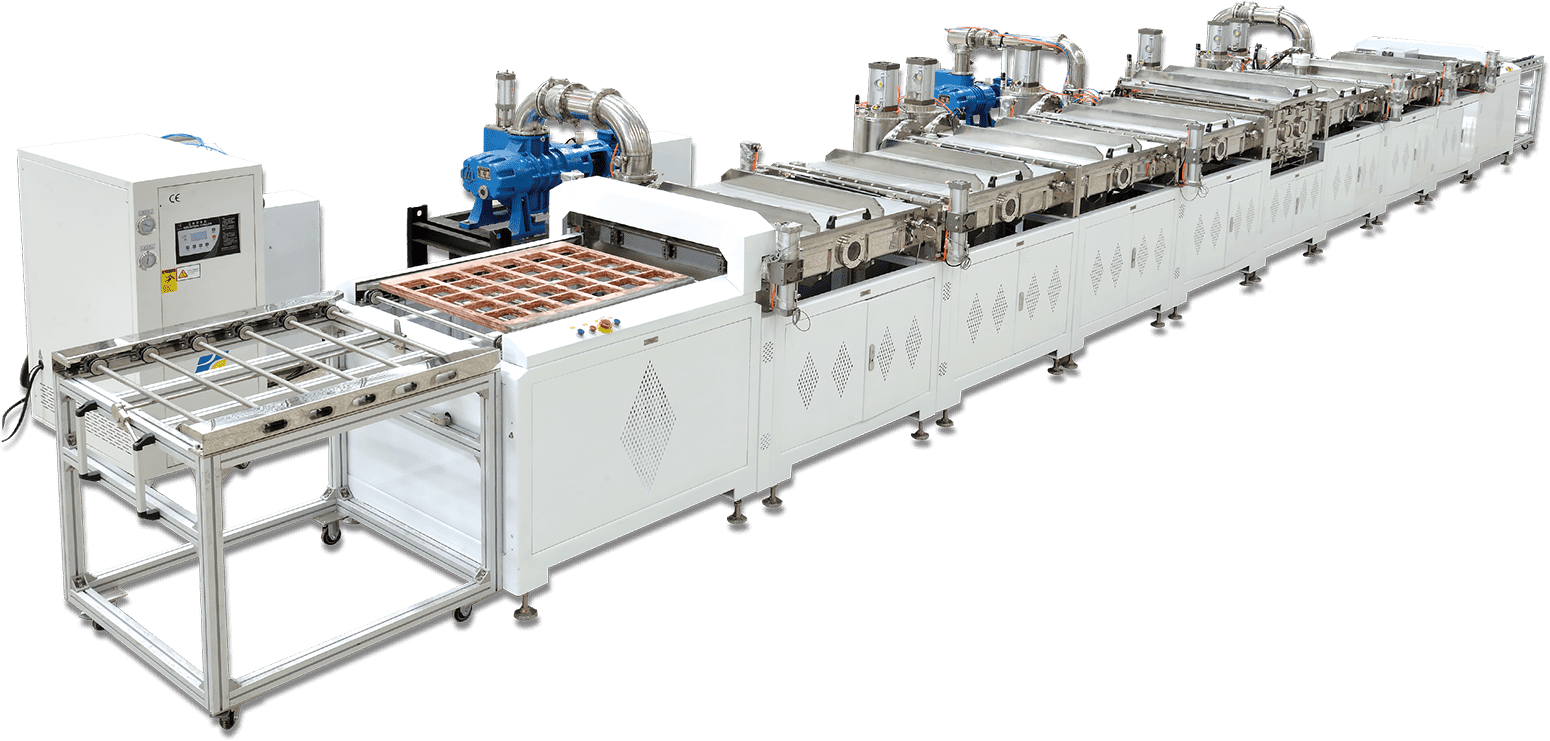

DPC Ceramic Substrate Double Side Inline Coater Supplier

Get A QuotePRODUCT DESCRIPTION

Equipment Advantage

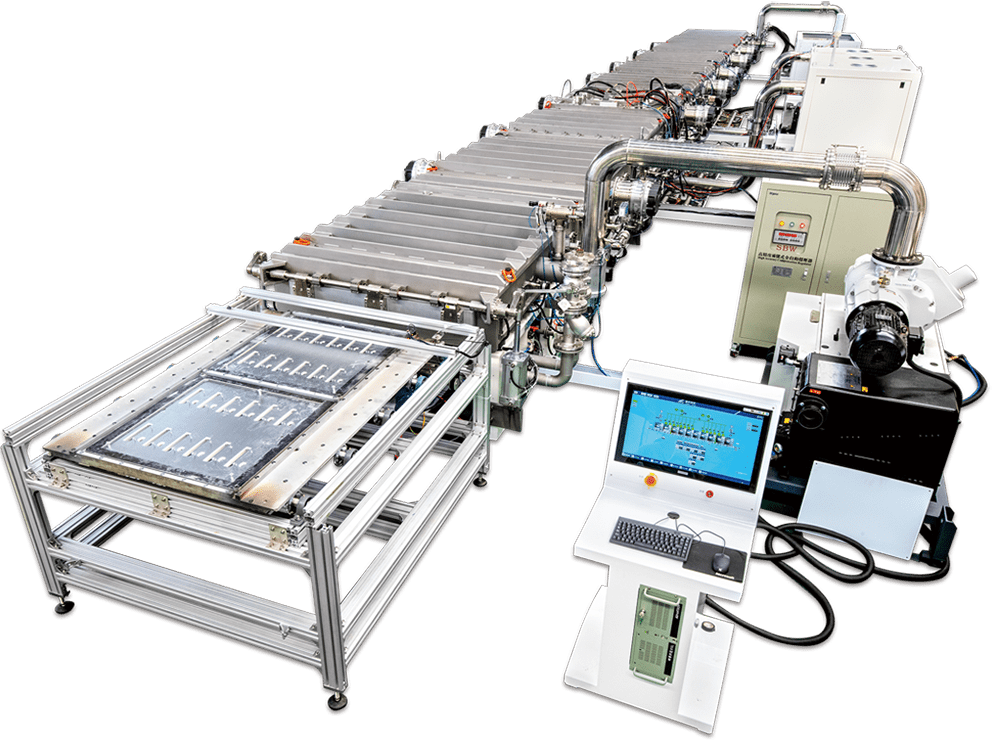

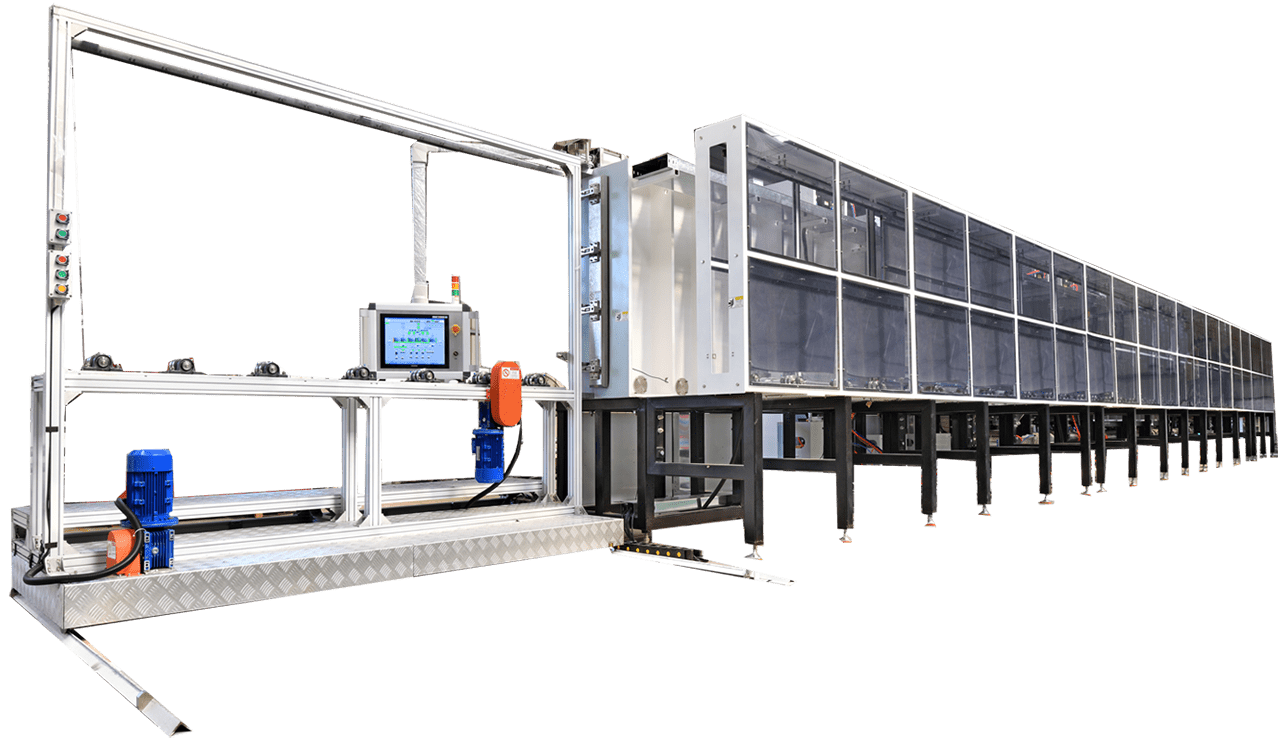

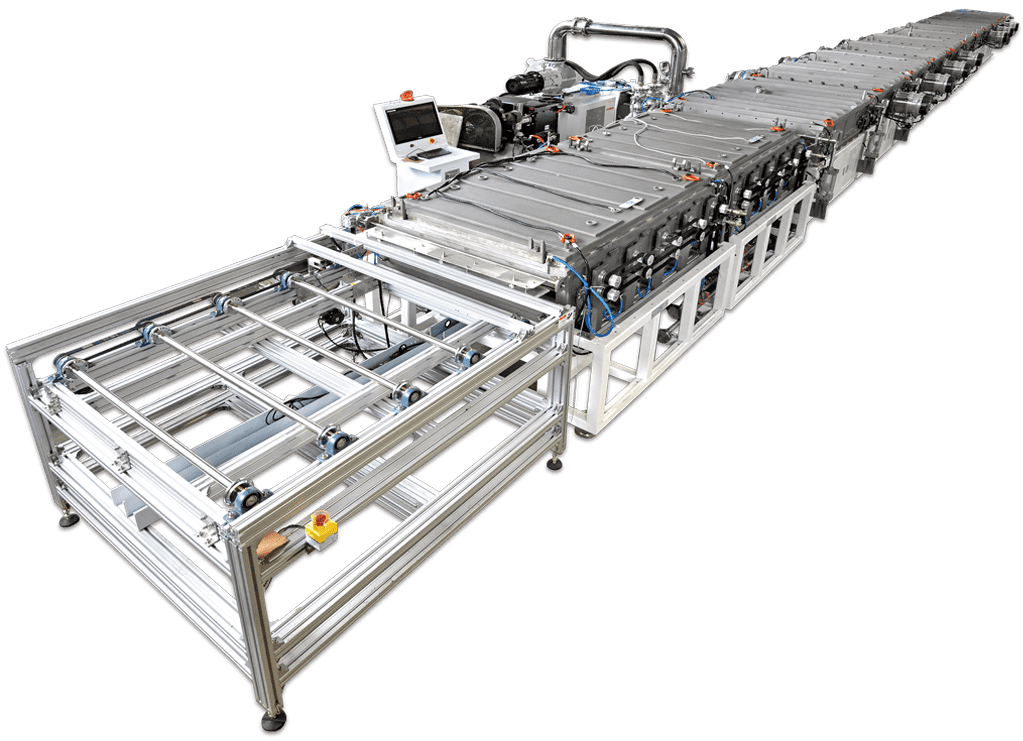

1.Scalable Functional Configuration

Utilizing a modular architecture design, it supports mass rapid production modes, allowing for the quick addition, removal, and reorganization of functional chambers. The layout of the production line can be flexibly adjusted according to production needs.

2.Precision Coating Technology Solution

Innovatively employing small-angle rotating target sputtering technology combined with an optimized magnetic field solution to achieve efficient filling of through-hole structures.

3.Adoption of Rotating Target Structure

This structure saves coating material loss and improves target material utilization. It also reduces the target replacement cycle, thereby enhancing production efficiency.

4.Process Control Advantages

Through the optimization of magnetron sputtering parameters and double-sided synchronous deposition technology, the coating efficiency of complex structural components is significantly improved, while the material loss rate is reduced.

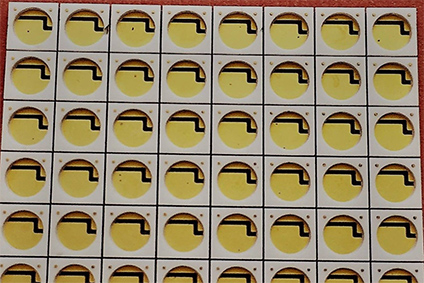

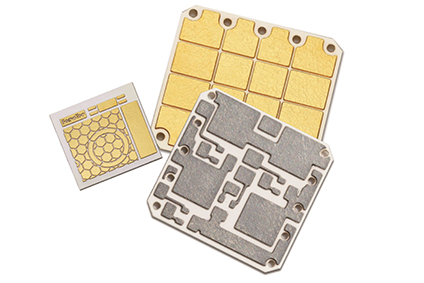

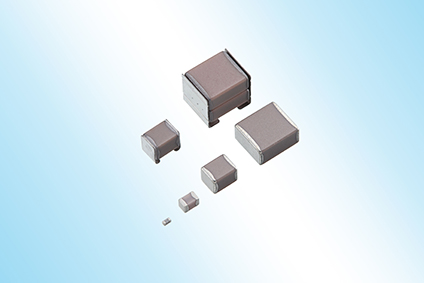

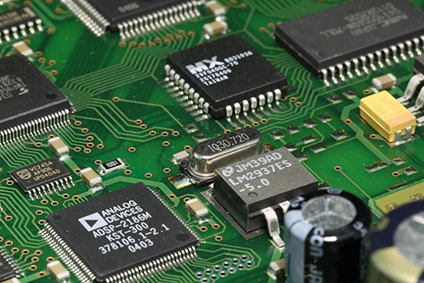

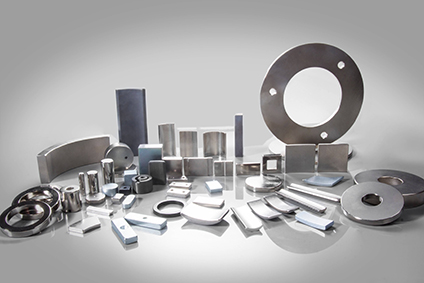

Application: Capable of preparing various single-element metal film layers such as Ti, Cu, Al, Sn, Cr, Ag, Ni, etc. It is widely used in semiconductor electronic components, such as DPC ceramic substrates, ceramic capacitors, thermistors, LED ceramic brackets, etc.