Bonvenon al Guangdong Zhenhua Teknologia Kompanio., Ltd.

Novaĵoj

-

Tipoj de CVD-Teknologio

Ĝenerale parolante, CVD povas esti malglate dividita en du tipojn: unu estas la vapora deponado de unu-kristala epitaksa tavolo de unuopa produkto sur la substrato, kiu estas mallarĝe CVD; la alia estas la deponado de maldikaj filmoj sur la substrato, inkluzive de plurproduktaj kaj amorfaj filmoj. Laŭ...Legu pli -

Transmisiaj kaj Reflektaj Spektroj kaj Koloro de Optikaj Maldikaj Filmoj Ĉapitro 2

El tio ni klarigos: (1) maldikfilmajn aparatojn, transmitancon, reflektajn spektrojn kaj la koloron de la koresponda rilato inter ili, tio estas, spektron de koloro; male, ĉi tiu rilato "ne estas unika", manifestiĝanta kiel multspektro de koloro. Tial, la filmo...Legu pli -

Transmisiaj kaj Reflektaj Spektroj kaj Koloro de Optikaj Maldikaj Filmoj Ĉapitro 1

Transmisiaj kaj reflektaj spektroj kaj koloroj de optikaj maldikaj filmoj estas du karakterizaĵoj de maldikaj filmaj aparatoj, kiuj ekzistas samtempe. 1. Transmisia kaj reflekta spektro estas la rilato inter reflektanco kaj transmitanco de optikaj maldikaj filmaj aparatoj kun ondolongo. Ĝi estas...Legu pli -

AF Maldika Filma Vaporiĝa Optika PVD Vakua Tegaĵa Maŝino

La vakua tegmaŝino AF Thin Film Vaporization Optical PVD estas desegnita por apliki maldikajn filmtegaĵojn al porteblaj aparatoj uzante la procezon de Fizika Vapora Deponado (PVD). La procezo implikas krei vakuan medion ene de tegaĵa ĉambro, kie solidaj materialoj vaporiĝas kaj poste deponiĝas...Legu pli -

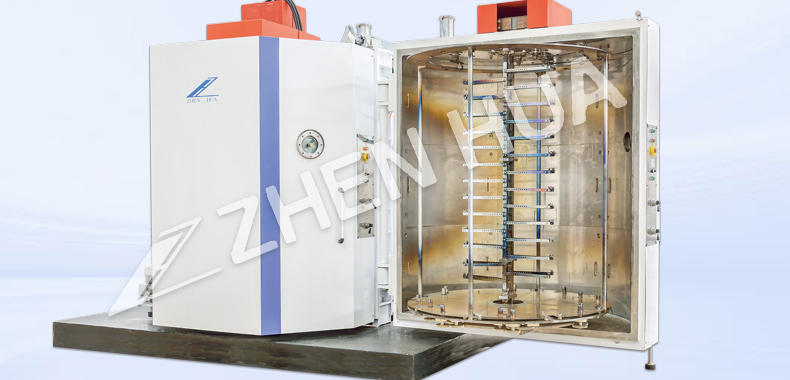

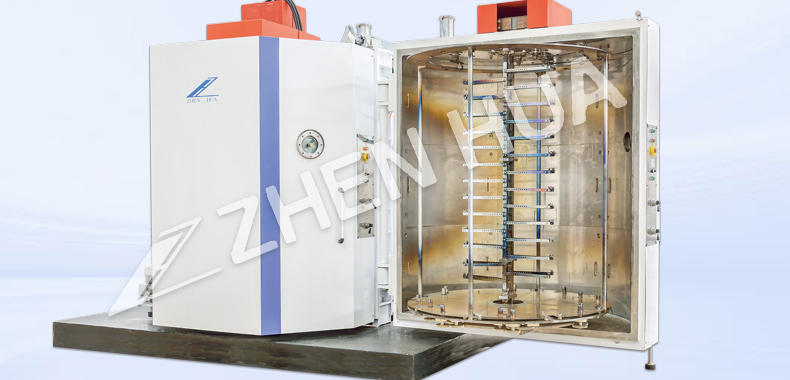

Aluminia arĝenta vakua tegaĵo spegula fabrikada maŝino

La maŝino por spegulfabrikado per vakua tegaĵo de aluminio kaj arĝento revoluciigis la spegulfabrikadan industrion per sia altnivela teknologio kaj preciza inĝenierado. Ĉi tiu pintnivela maŝino estas desegnita por apliki maldikan tavolon de aluminio kaj arĝento al la surfaco de vitro, kreante altkvalitajn...Legu pli -

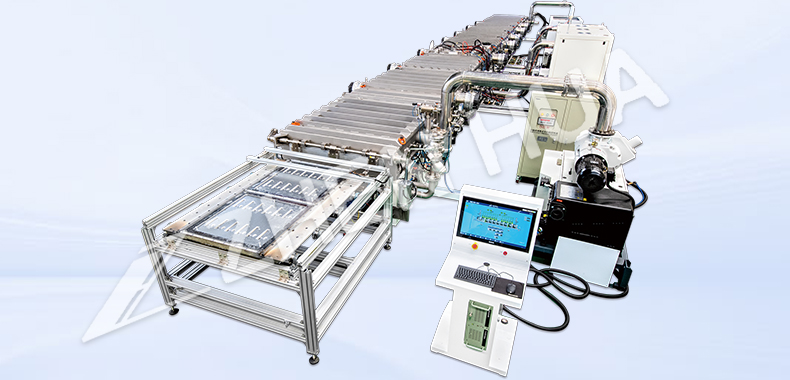

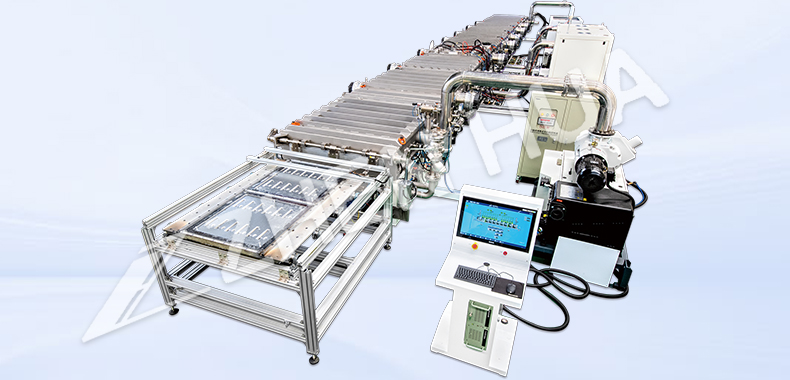

Optika vakua tegaĵmaŝino

La optika vakua metaligilo estas pintnivela teknologio, kiu revoluciigis la industrion de surfacaj tegaĵoj. Ĉi tiu progresinta maŝino uzas procezon nomatan optika vakua metalizado por apliki maldikan tavolon de metalo al diversaj substratoj, kreante tre reflektan kaj daŭran surfacon...Legu pli -

Plasmo Plifortigita Kemia Vapora Deponado Ĉapitro 2

Plej multaj kemiaj elementoj povas esti vaporigitaj per kombinado de ili kun kemiaj grupoj, ekzemple Si reagas kun H por formi SiH4, kaj Al kombiniĝas kun CH3 por formi Al(CH3). En la termika CVD-procezo, la supre menciitaj gasoj absorbas certan kvanton da termika energio dum ili trapasas la varmigitan substraton kaj formas re...Legu pli -

Plasmo Plifortigita Kemia Vapora Deponado Ĉapitro 1

Kemia Vapora Deponado (KVA). Kiel la nomo sugestas, ĝi estas tekniko kiu utiligas gasajn antaŭajn reakciantojn por generi solidajn filmojn per atomaj kaj intermolekulaj kemiaj reakcioj. Male al PVD, la KVA-procezo plejparte efektiviĝas en pli alta premo (pli malalta vakuo) medio, kun...Legu pli -

Procezaj Elementoj kaj Agaj Mekanismoj influantaj la kvaliton de maldikaj filmaj aparatoj (Parto 2)

3. Influo de substrata temperaturo Substrata temperaturo estas unu el la gravaj kondiĉoj por membrana kresko. Ĝi provizas plian energian suplementon al la membranaj atomoj aŭ molekuloj, kaj ĉefe influas la membranan strukturon, aglutinan koeficienton, ekspansian koeficienton kaj agregaĵ...Legu pli -

Procezaj Faktoroj kaj Mekanismoj influantaj la kvaliton de maldikaj filmaj aparatoj (Parto 1)

La fabrikado de optikaj maldikaj filmaj aparatoj estas efektivigata en vakua ĉambro, kaj la kresko de la filmtavolo estas mikroskopa procezo. Tamen, nuntempe, la makroskopaj procezoj, kiujn oni povas rekte kontroli, estas iuj makroskopaj faktoroj, kiuj havas nerektan rilaton kun la kvalito...Legu pli -

Enkonduko al la historio de disvolviĝo de vaporiĝa teknologio

La procezo de varmigado de solidaj materialoj en altvakua medio por sublimiĝi aŭ vaporiĝi kaj deponi ilin sur specifan substraton por akiri maldikan filmon estas konata kiel vakua vaporiĝa tegaĵo (nomata vaporiĝa tegaĵo). La historio de la preparado de maldikaj filmoj per vakua vaporiĝa...Legu pli -

Enkonduko al ITO-tegaĵo

Indio-stanoksido (indio-stanoksido, nomata ITO) estas larĝa bendbreĉo, forte dopita n-tipa duonkonduktaĵa materialo, kun alta videbla lumtransmisio kaj malaltaj rezistecaj karakterizaĵoj, kaj tial vaste uzata en sunĉeloj, plataj ekranoj, elektrokromaj fenestroj, neorganikaj kaj organikaj...Legu pli -

Laboratoria vakua spino-tegaĵmaŝino

Laboratoriaj vakuaj rotaciaj tegaĵoj estas gravaj iloj en la kampo de maldika filmdemetado kaj surfacmodifo. Ĉi tiu altnivela ekipaĵo estas desegnita por precize kaj egale apliki maldikajn filmojn el diversaj materialoj al substratoj. La procezo implikas la aplikon de likva solvaĵo aŭ sus...Legu pli -

Jona fasko-helpata depozicia reĝimo kaj ĝia energia selektado

Ekzistas du ĉefaj reĝimoj de jonfasko-helpata deponado, unu estas dinamika hibrido; la alia estas statika hibrido. La unua rilatas al la filmo en la kreskoprocezo ĉiam akompanata de certa energio kaj faskofluo de jona bombado kaj filmo; la dua estas antaŭdeponita sur la surfaco de la...Legu pli -

Jona Traba Depozicia Teknologio

① Jona faskohelpata deponado-teknologio karakteriziĝas per forta adhero inter la filmo kaj la substrato, la filmotavolo estas tre forta. Eksperimentoj montris, ke: jona faskohelpata deponado de adhero ol la adhero de termika vapora deponado pliiĝis plurfoje al centoj ...Legu pli