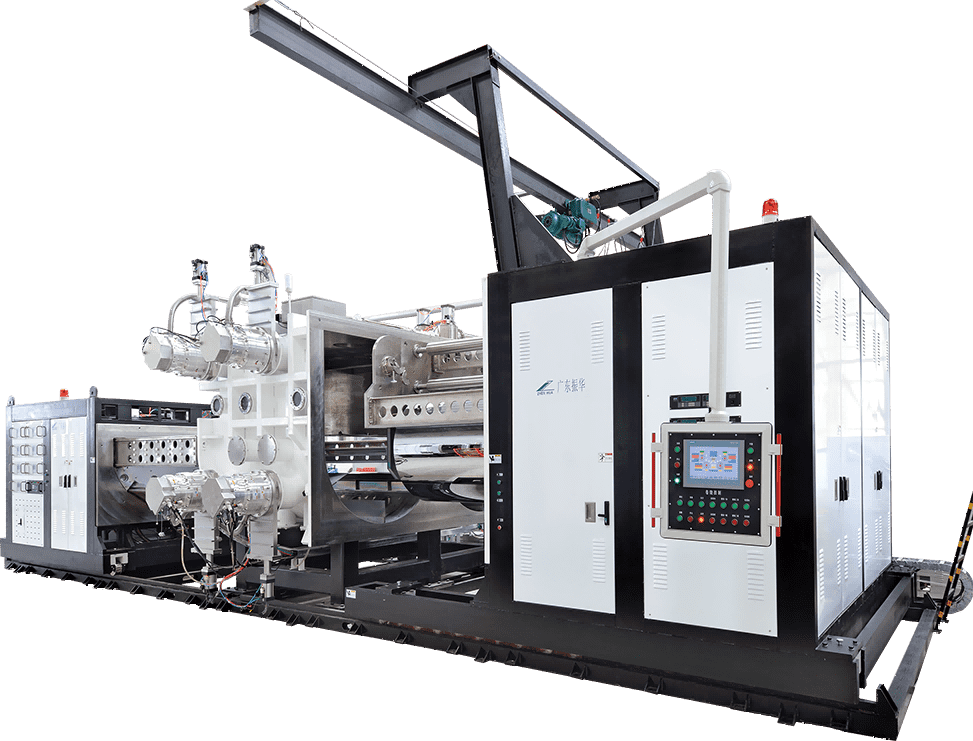

Factory supplied Metal Pvd Coating Machine - Vertical double door multifunctional coating equipment – Zhenhua

PRODUCT DESCRIPTION

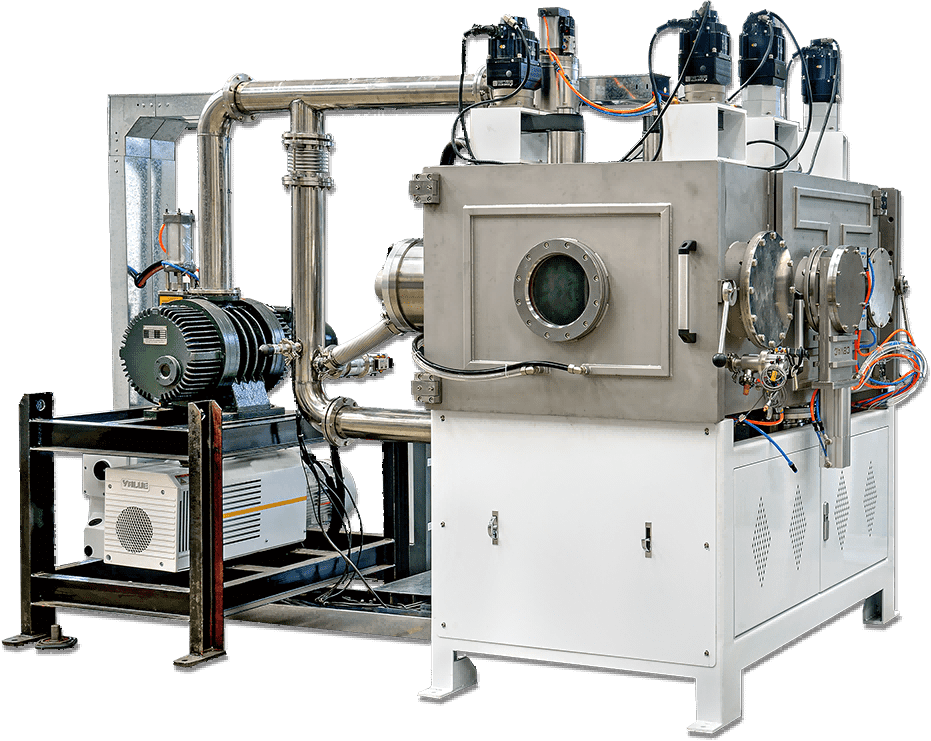

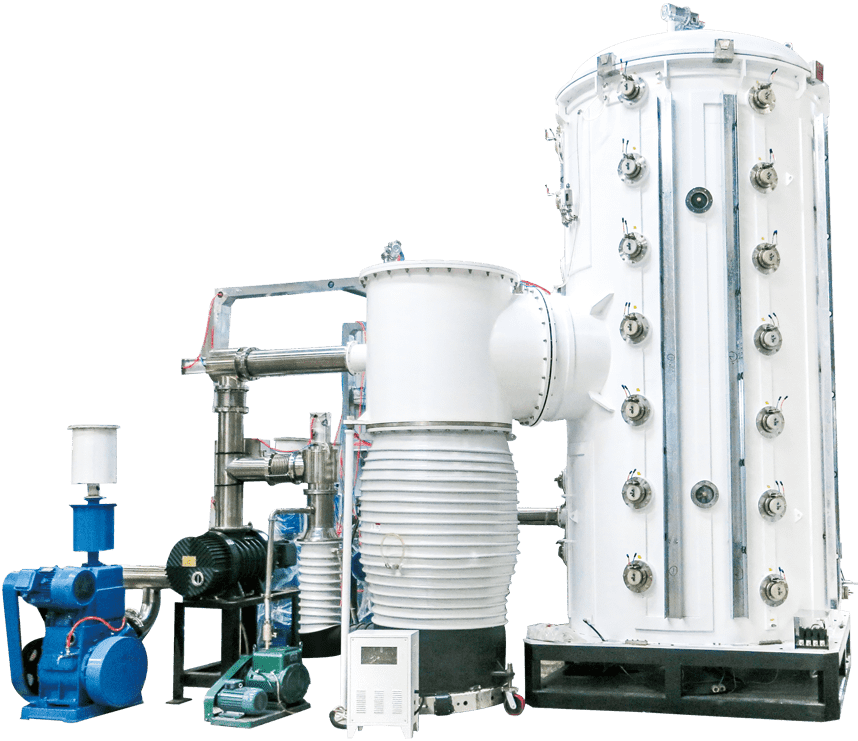

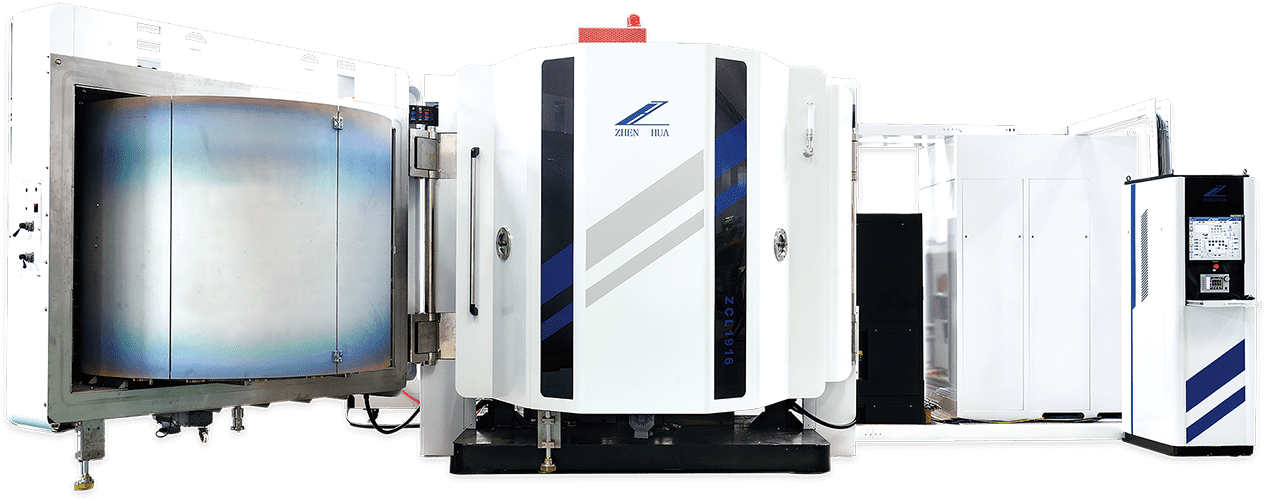

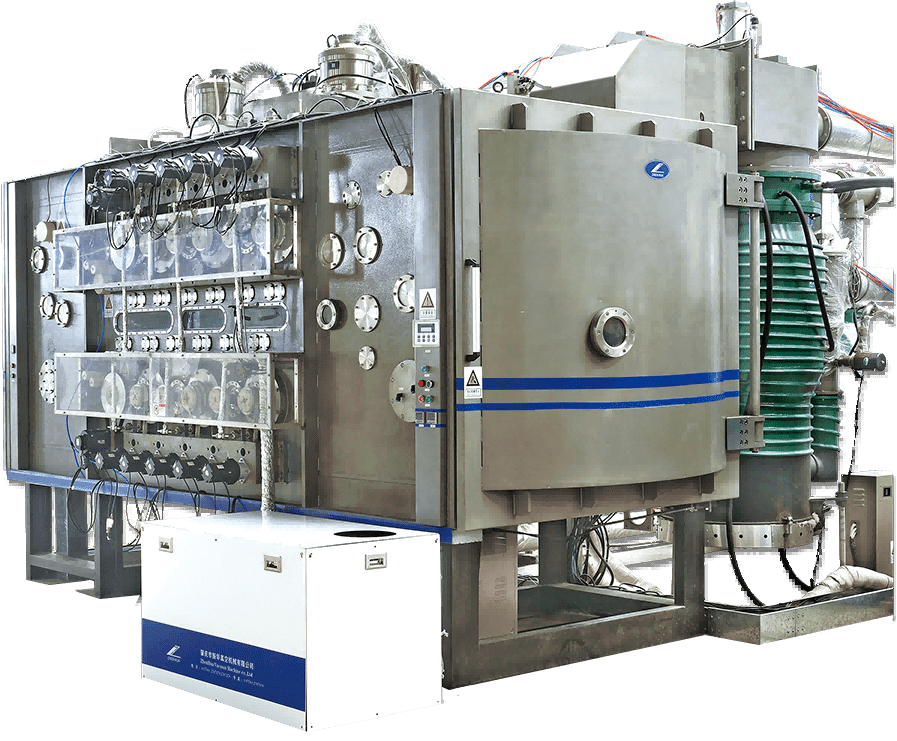

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technology and medium frequency ion cleaning system. It is suitable for customers’ complex product process switching. The metal film and protective film manufacturing process can be completed in the vacuum chamber at one time to prevent secondary process pollution.

1. The equipment has compact structure and small floor area.

2. Double door structure, no standby time, high production efficiency.

3. The coating film has good uniformity and high finish.

The equipment can be applied to different products such as lamps, vehicle logos and automotive interior trim parts, and can be coated with metal films, such as Ti, Cu, Al, Cr, Ni, SUS, Sn, In and other materials.

The equipment can be applied to different products such as lamps, vehicle logos and automotive interior trim parts, and can be coated with metal films, such as Ti, Cu, Al, Cr, Ni, SUS, Sn, In and other materials.

Optional models

| ZCM1417 |

| φ1400*H1700(mm) |

PRODUCT FEATURE

INDUSTRY APPLICATION

RELATIVE DEVICES

Click ViewFactory source Jewelry Wear-Resistant Coating E...

The equipment integrates magnetron sputtering and ion coating technology, providing a solution for improving color consistency, deposition rate and stability of compound composition. According to d...

OEM/ODM Factory Pvd Coating Machine Korea - O...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Factory directly supply Car Light Thermal Evapo...

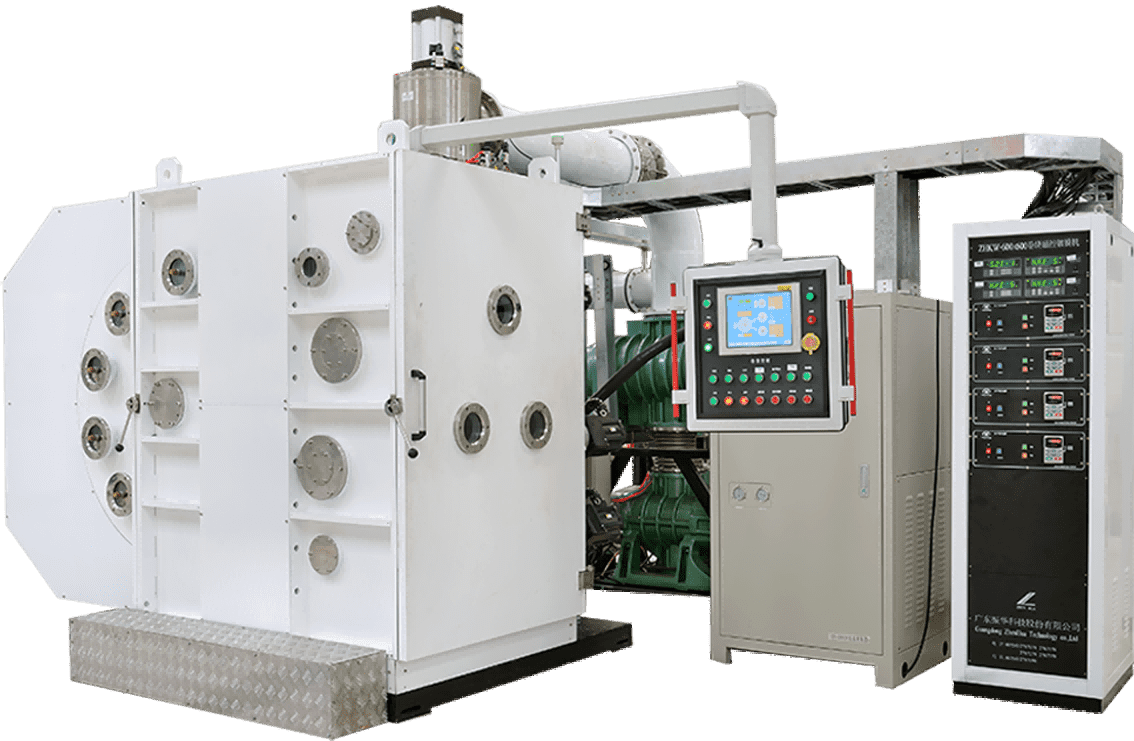

Magnetron winding coating equipment is to use magnetron sputtering method to change the coating material into gaseous or ionic state in the vacuum environment, and then deposit it on the work-piece...

18 Years Factory Non Conductive Coating Of Mobi...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Reliable Supplier Metal Gold Evaporation Coatin...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

2022 New Style Bipolar Plate Coating Machine -...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory supplied Vertical Evaporation Coating M...

The anti fingerprint coating equipment adopts the magnetic control coating AF anti fingerprint technology, and the anti fingerprint water drop angle can reach more than 115 °. The film has good hyd...

Cheap PriceList for Continuous Coating Line - ...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

Best-Selling Post Oxidation Coating - Hardness...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

Factory directly supply Car Light Thermal Evapo...

The equipment integrates magnetron sputtering and ion coating technology, and provides a solution for improving color consistency, deposition rate and stability of compound composition. According t...

8 Year Exporter Magnetron Sputter Vacuum Coatin...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Quality Inspection for Metal Coating Equipment ...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Manufacturer for Vacuum Coating Equipment For S...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

Professional Design Magnetron Sputter Vacuum Co...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

factory low price Vacuum Evaporation Coating Eq...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

High definition Small Pvd Coating Equipment - ...

The equipment adopts the cathode arc evaporation ion coating technology, which has the characteristics of fast deposition rate, high energy and high metal ionization rate. The cathode arc can be co...

Hot-selling Al Coating - Special equipment for...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Factory Supply Lithium Supplement By Vacuum Coa...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Factory making Evaporation Magnetron Sputtering...

This series of equipment converts the coating materials with low melting point and easy to evaporate into nano particles by heating in the medium frequency induction furnace or evaporation molybden...

One of Hottest for Magnetron Sputtering Equipme...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

High definition Lithium Battery PET Film Alumin...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Good Quality Metal Gold Evaporation Coating Mac...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Trending Products Chrome Pvd Coating Machine -...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Top Suppliers Gradual Color Coating Equipment -...

Magnetron winding coating equipment is to use magnetron sputtering method to change the coating material into gaseous or ionic state in the vacuum environment, and then deposit it on the work-piece...

OEM Supply Buy Coating Machine Vacuum - Specia...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Discount wholesale Magnetron Coating Equipment ...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

High Quality for Anti Fingerprint AF Coating Ma...

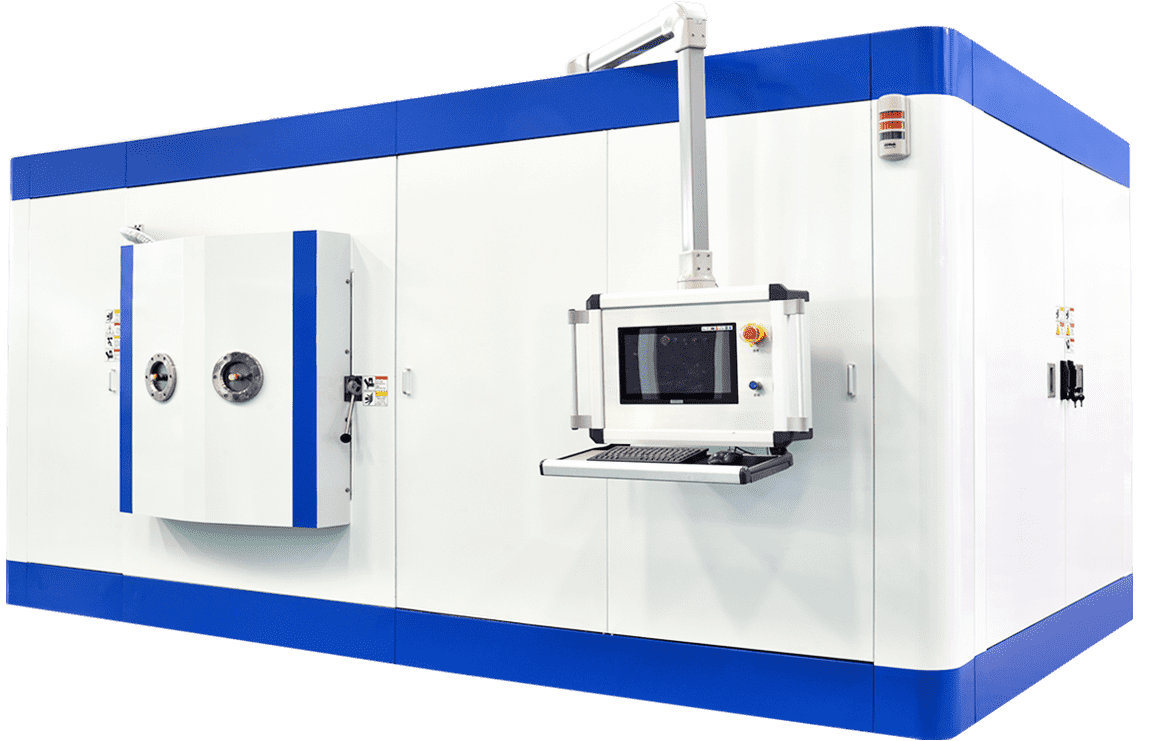

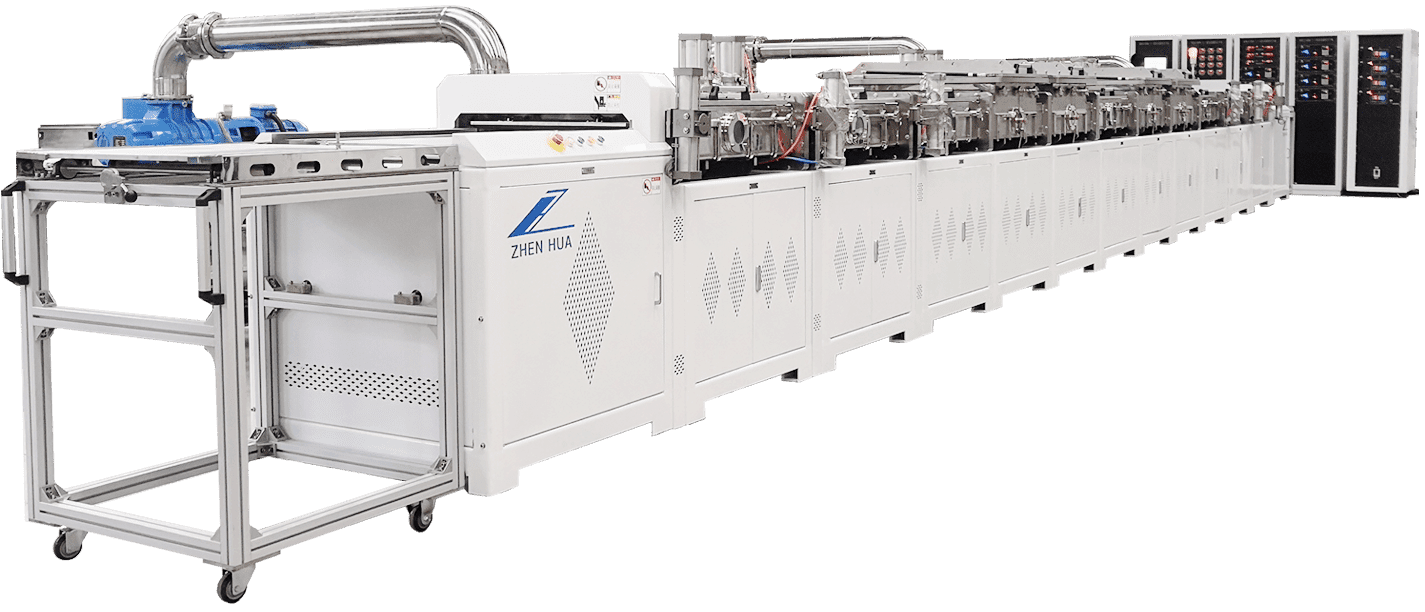

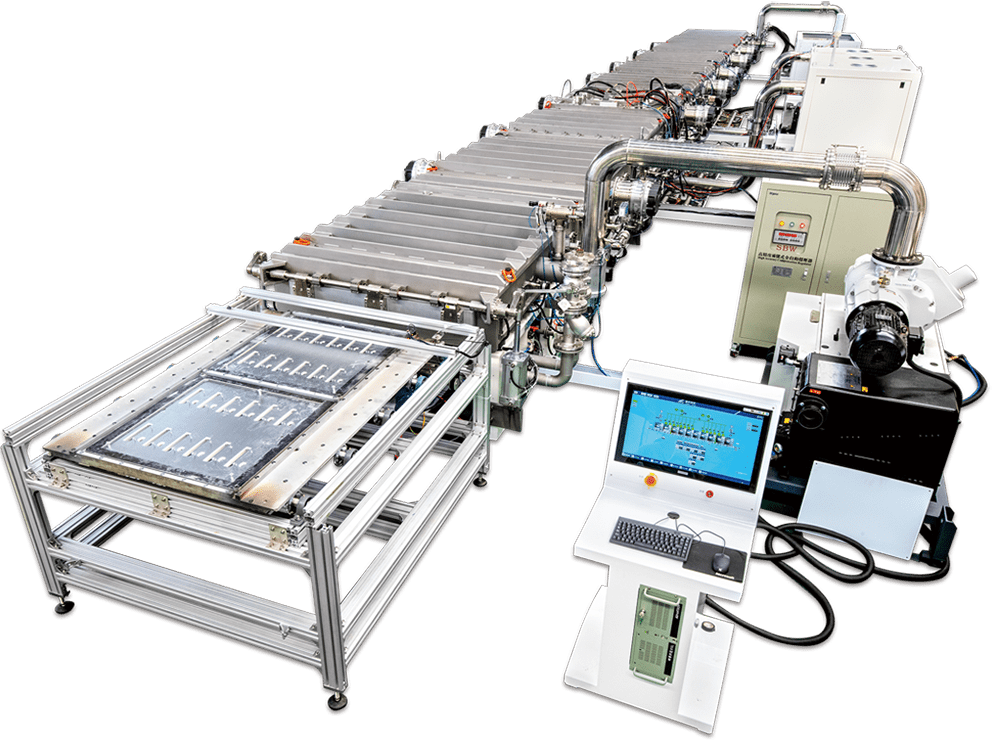

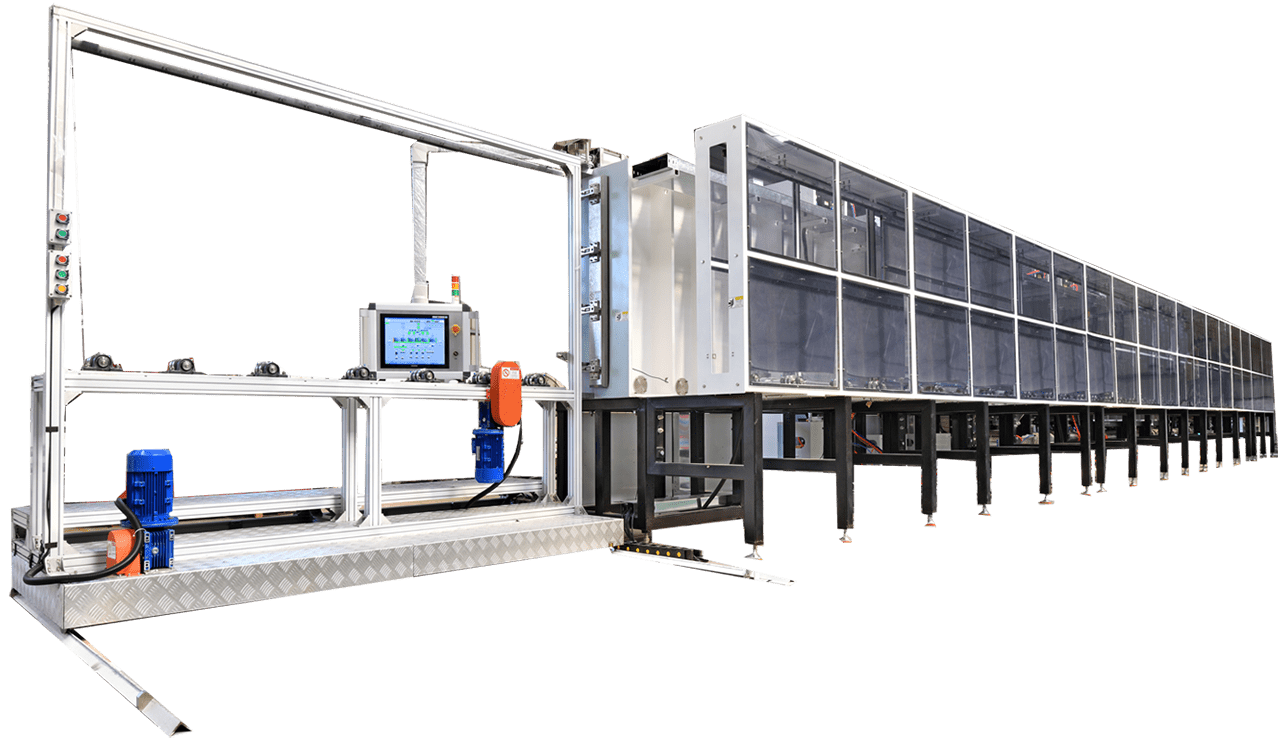

ITO / ISI horizontal continuous coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion and upgrad...

Good quality Lithium Battery Compound Aluminium...

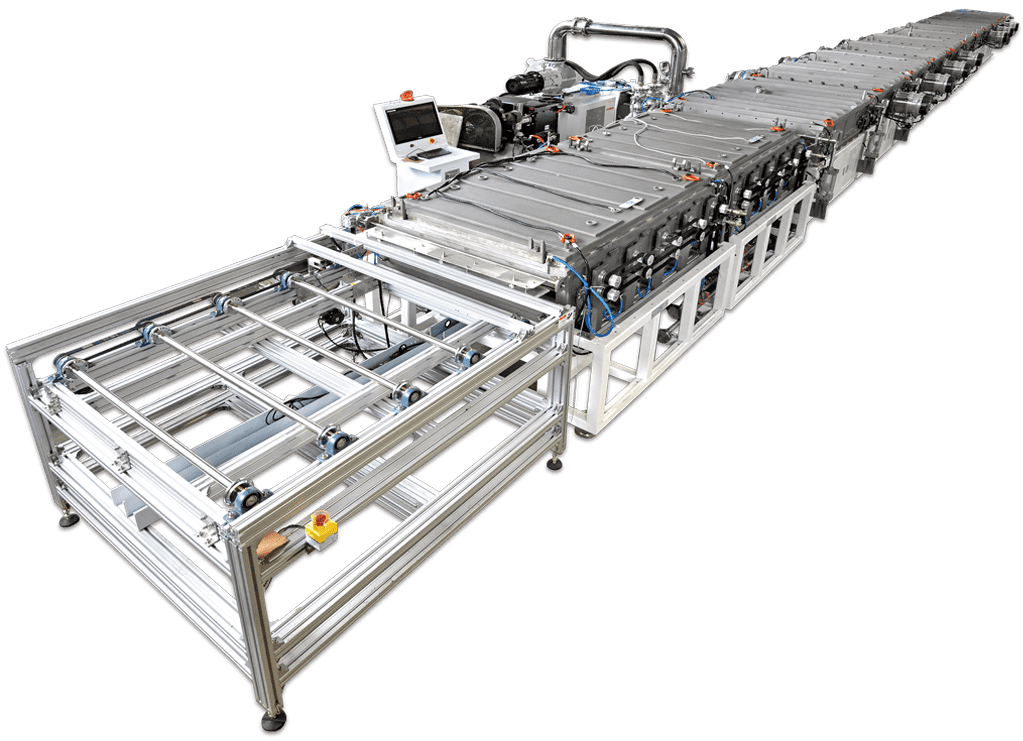

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Personlized Products Vacuum Coating Equipment F...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

Best-Selling PCB Micro Drill Coating Machine -...

Magnetron winding coating equipment is to use magnetron sputtering method to change the coating material into gaseous or ionic state in the vacuum environment, and then deposit it on the work-piece...

Factory best selling Vacuum Coating Equipment P...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Wholesale Discount Pvd Coating Equipment Suppli...

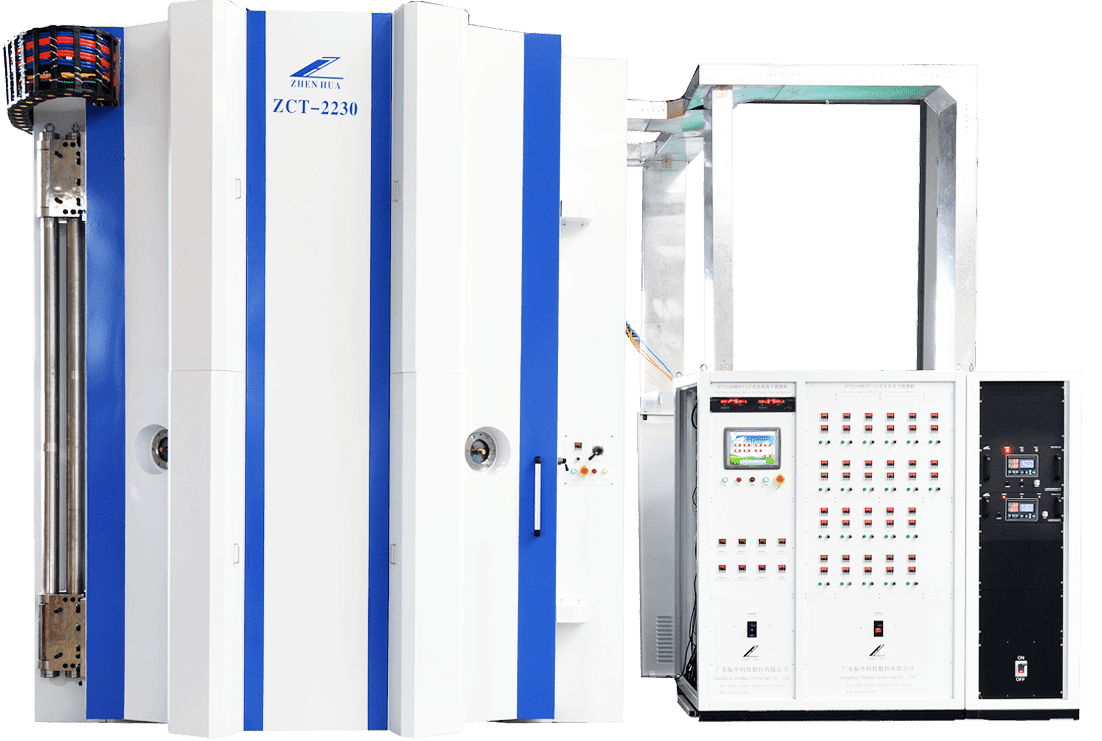

Optional models Vertical multifunctional coating production line Vertical decorative film coating production line

High reputation China Vacuum Coating Machine Su...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Leading Manufacturer for Vacuum Metalizing Equi...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Wholesale Pvd Equipments - GX600 small electro...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

2022 New Style 9H Hard Coating Machine - Doubl...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

OEM/ODM China TaC Hard Coating - Vertical doub...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Ordinary Discount Chrome Pvd Coating Equipment ...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Super Lowest Price Vacuum Coating Machine India...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Good quality Pvd Vacuum Coating Machine - Expe...

The equipment integrates magnetron sputtering and ion coating technology, and provides a solution for improving color consistency, deposition rate and stability of compound composition. According t...

Cheapest Factory Hard Coat Anodizing Machine -...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Factory making Pvd Coating Machine Suppplier -...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

2022 Latest Design Golf Head Vacuum Coating Equ...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

New Fashion Design for Bipolar Plate Anti-Corro...

The equipment integrates magnetron sputtering and ion coating technology, providing a solution for improving color consistency, deposition rate and stability of compound composition. According to d...

Massive Selection for Pvd Titanium Coating Equi...

The anti fingerprint coating equipment adopts the magnetic control coating AF anti fingerprint technology, and the anti fingerprint water drop angle can reach more than 115 °. The film has good hyd...

Factory Price For 9H Hard Coating Device - Exp...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Factory Price Gold Sputtering Equipment - Larg...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

2022 High quality Vacuum Coating Equipment - S...

In the vacuum state, place the workpiece on the cathode of low-pressure glow discharge and inject appropriate gas. At a certain temperature, a coating is obtained on the surface of the workpiece by...

OEM Manufacturer Buy Vacuum Coating Machine - ...

Sapphire film hard coating equipment is a professional equipment for depositing sapphire film. The equipment integrates three coating systems of medium frequency reactive magnetron sputtering + CVD...

100% Original Factory Evaporation Magnetron Spu...

The equipment adopts the cathode arc evaporation ion coating technology, which has the characteristics of fast deposition rate, high energy and high metal ionization rate. The cathode arc can be co...

Renewable Design for Stainless Steel Pvd Coatin...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

factory low price Car Lamp Thermal Evaporation ...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Massive Selection for Gold Sputtering Machine -...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Hot sale Electron Beam Vacuum Coating Machine -...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

New Arrival China Sputtering Equipment Manufact...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

Ordinary Discount Pvd Hard Surface Coating Equi...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

China New Product Lithium Battery Compound Copp...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

High Quality Car Light Coating Machine - Large...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Factory Cheap Pvd Machine Price - Oxidation r...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Massive Selection for Pvd Titanium Coating Equi...

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

factory Outlets for Metal Pvd Coating Equipment...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

100% Original China Pvd Coating Equipment - GX...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

China wholesale Hard Chrome Coating Equipment -...

With the rapid growth of the market demand for improving the wear resistance, lubrication, corrosion resistance and other properties of hard coatings, cathodic arc magnetic filtration ion coating e...

Ordinary Discount Vacuum Sputtering Machine - ...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Super Purchasing for Pvd Chrome Coating Equipme...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

Popular Design for Chrome Plating Equipment - ...

The equipment integrates magnetron sputtering and ion coating technology, providing a solution for improving color consistency, deposition rate and stability of compound composition. According to d...

Professional Design Titanium Nitride Coating Pv...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Factory wholesale Pvd Metallization Vacuum Coat...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Short Lead Time for Photovoltaic Glass Coating ...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Chinese wholesale Coating Equipment Vacuum - G...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory wholesale TOPCON Battery Coating - Spe...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

PriceList for AF Coatig Of Jewelry - Special h...

The equipment adopts cathode arc ion coating technology and is equipped with advanced IET etching system. After treatment, the product can directly deposit hard coating without transition layer. At...

Factory Supply Lithium Supplement By Vacuum Coa...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

2022 New Style Sputtering Equipment Coating - ...

Optional models Vertical multifunctional coating production line Vertical decorative film coating production line

Original Factory Cvd Diamond Coating Equipment ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

factory Outlets for Tools Pvd Coating Machine -...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Factory Outlets Magnetron Sputtering Coating Eq...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Renewable Design for Stainless Steel Pvd Coatin...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

100% Original Anti Oxidation Coating Of Jewelry...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Cheap price Anti Oxidation Film Layer Of Jewelr...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

PriceList for On Board Display Coating Equipmen...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

High Quality Pvd Coating Machine - Vacuum plas...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

OEM Manufacturer Buy Vacuum Coating Machine - ...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Discount wholesale Gold Pvd Coating Equipment -...

With the rapid growth of the market demand for improving the wear resistance, lubrication, corrosion resistance and other properties of hard coatings, cathodic arc magnetic filtration ion coating e...

Factory wholesale Pvd Coating Equipment - Expe...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...