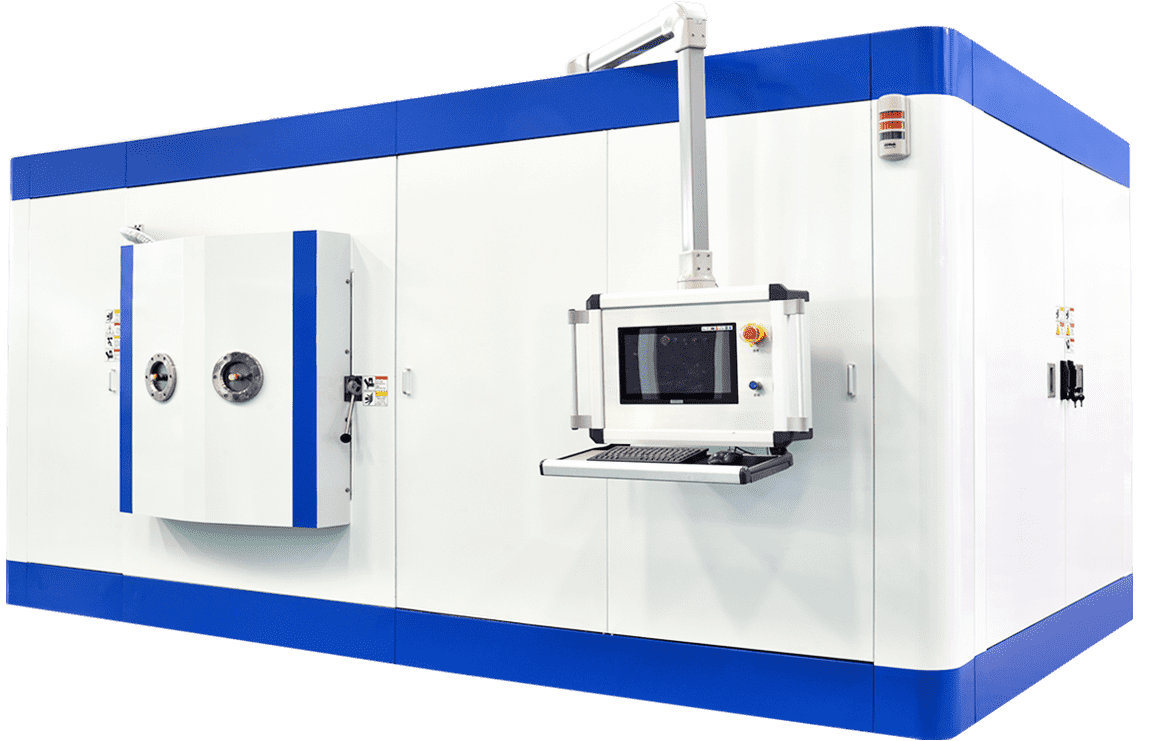

GX2050 Cosmetic Anti-forgery Ink Optical Coating Machine

Get A QuotePRODUCT DESCRIPTION

Equipment advantages

The equipment utilizes electron beam evaporation technology, where electrons are emitted from the cathode filament and focused into a specific beam current. The beam is then accelerated by the potential between the cathode and the crucible, causing the coating material to melt and evaporate. This method is characterized by high energy density, enabling the evaporation of materials with melting points exceeding 3000 degrees Celsius. The resulting film layers exhibit high purity and thermal efficiency.

The equipment is equipped with an electron beam evaporation source, an ion source, a film thickness monitoring system, a film thickness correction structure, and a stable umbrella-shaped workpiece rotation system. The ion source assists in the coating process, enhancing the density of the film layers, stabilizing the refractive index, and preventing wavelength shifts due to moisture. The fully automatic real-time film thickness monitoring system ensures process repeatability and stability. Additionally, the equipment features a self-feeding function, reducing the dependency on operator skill.

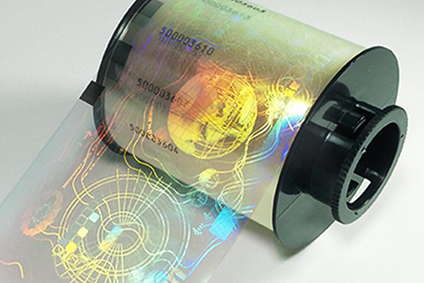

This equipment is suitable for various oxide and metal coating materials. It can deposit multilayer precision optical films, such as AR (anti-reflective) coatings, long-pass filters, short-pass filters, brightness enhancement films, AS/AF (anti-smudge/anti-fingerprint) coatings, IRCUT filters, color filter systems, and gradient films. It is widely used in applications such as mobile phone glass covers, camera lenses, eyeglass lenses, optical lenses, swimming goggles, ski goggles, PET film sheets/composite boards, PMMA (polymethyl methacrylate), photochromic magnetic films, anti-counterfeiting, and cosmetics.