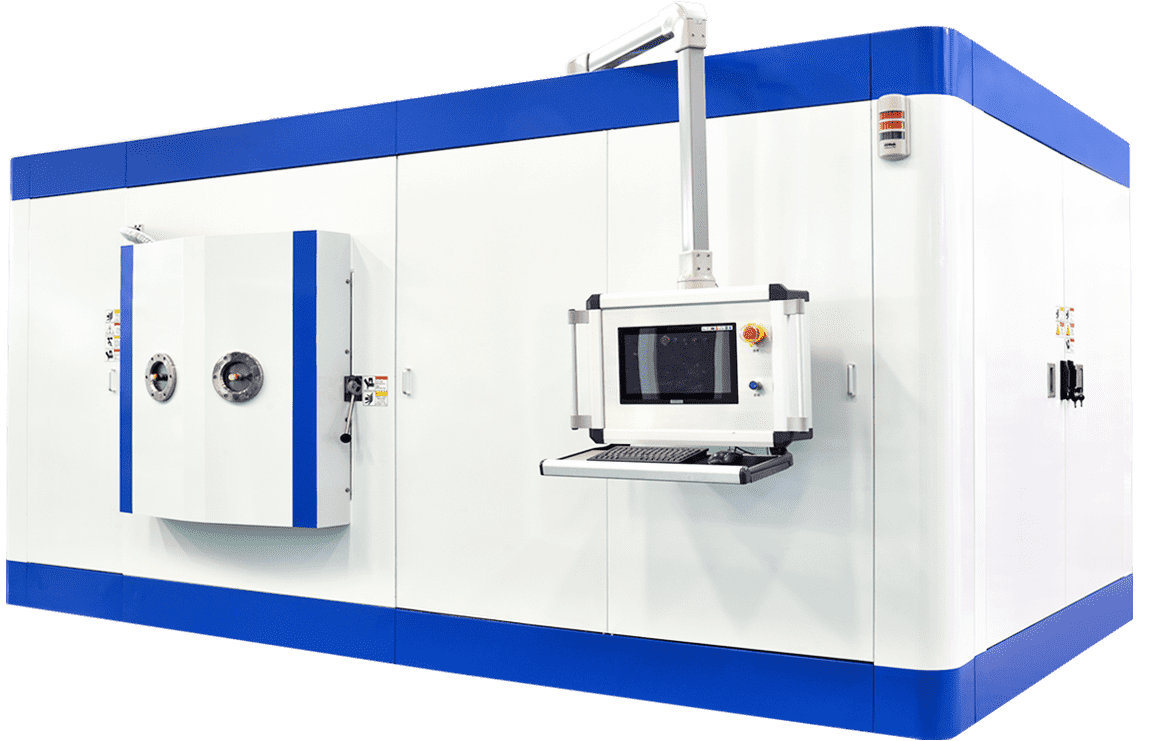

PRODUCT DESCRIPTION

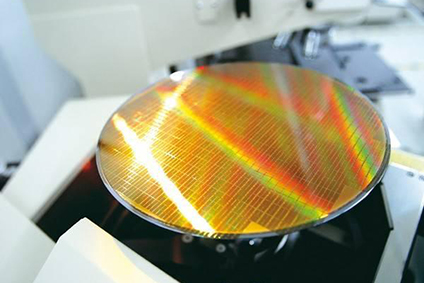

The equipment adopts vertical front door structure and cluster layout. It can be equipped with evaporation sources for metals and various organic materials, and can evaporate silicon wafers of various specifications. Equipped with precision alignment system, the coating is stable and the coating has good repeatability.

GX600 coating equipment can accurately, evenly and controllably evaporate organic light-emitting materials or metal materials onto the substrate. It has the advantages of simple film formation, high purity and high compactness. The full-automatic film thickness real-time monitoring system can ensure the repeatability and stability of the process. It is equipped with self melting function to reduce the dependence on the operator's skills.

The equipment can be applied to Cu, Al, Co, Cr, Au, Ag, Ni, Ti and other metal materials, and can be coated with metal film, dielectric layer film, IMD film, etc. it is mainly used in the semiconductor industry, such as power devices, semiconductor rear packaging substrate coating, etc.

Optional models

| GX600 | GX900 |

| φ600*800(mm) | φ900*H1050(mm) |