Nkọwa ngwaahịa

Ngwa ahụ na-anabata teknụzụ mkpuchi cathode arc ion ma kwadebere ya na sistemụ etching IET dị elu. Mgbe ọgwụgwọ gasịrị, ngwaahịa ahụ nwere ike itinye mkpuchi siri ike ozugbo na-enweghị oyi akwa mgbanwe. N'otu oge ahụ, a na-akwalite nkà na ụzụ arc ọdịnala ka ọ bụrụ magnet na-adịgide adịgide gbakwunyere teknụzụ nyocha eriri electromagnetic. Teknụzụ a nwere ike ịkwalite ike ion nke ọma, melite ọnụego ionization na ọnụego ojiji ebumnuche, mee ngwa ngwa ngagharị ngagharị nke arc, gbochie ọgbọ nke ụmụ irighiri mmiri nke ọma, belata ịdị njọ nke ihe nkiri ahụ, wee belata ọnụọgụ esemokwu nke ihe nkiri ahụ. Karịsịa maka ebumnuche aluminom, ọ nwere ike melite ndụ ọrụ nke workpiece. N'iji ngwa 3D dị fechaa kacha ọhụrụ, ịdị n'otu na nkwụsi ike ka mma.

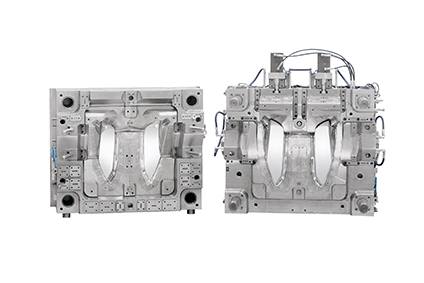

Enwere ike kpuchie akụrụngwa ahụ na AlTiN / AlCrN / TiCrAlN / TiAlSiN / CrN na mkpuchi mkpuchi dị elu nke ukwuu, nke ejirila ya mee ihe na ebu, ihe ịkpụ, ọkpọ ọkpọ, akụkụ akpaaka, plunger na ngwaahịa ndị ọzọ.

Nka nka

1. Plasma kwalitere, ike electromagnetic na-atụgharị nyocha nyocha na-akpụ akpụ oyi cathode, diffraction siri ike, ihe nkiri siri ike.

2. ogologo sputtering anya, elu ike na ezi adhesion.

3. Enwere ike idozi anya nke arc na-egbu anode na-enweghị nkwụsị maka mmezi.

4. Usoro ntụgharị ntụgharị dị mma iji dochie ma nọgide na-enwe cathode oyi.

5. ọnọdụ ntụpọ arc nwere ike ịchịkwa, na ụdị oghere magnetik dị iche iche nwere ike gbanwee dịka ihe dị iche iche si dị.

Ihe atụ nke ihe mkpuchi

| Mkpuchi | Ọkpụrụkpụ (um) | Isi ike (HV) | Oke okpomọkụ (℃) | Agba | Ngwa |

| Ta-C | 1-2.5 | 4000-6000 | 400 | Nwa | Graphite, carbon fiber, composites, aluminum and aluminum alloys |

| TiSiN | 1-3 | 3500 | 900 | Ọla | 55-60HRC igwe anaghị agba nchara, mma imecha |

| AlTiN-C | 1-3 | 2800-3300 | 1100 | Agba ntụ na-acha anụnụ anụnụ | Low hardness igwe anaghị agba nchara ọnwụ, akpụ ebu, stamping ebu |

| CrAlN | 1-3 | 3050 | 1100 | Agba ntụ | Mkpụcha dị arọ na ịkpụzi ebu |

| CrAlSiN | 1-3 | 3520 | 1100 | Agba ntụ | 55-60HRC igwe anaghị agba nchara, mma imecha, akọrọ ọnwụ |

Ụdị nhọrọ

| HDA0806 | HDA1112 |

| φ850*H600(mm) | φ1100*H1200(mm) |