No.1 Ụkpụrụ nke nnukwu ike pulsed magnetron sputtering

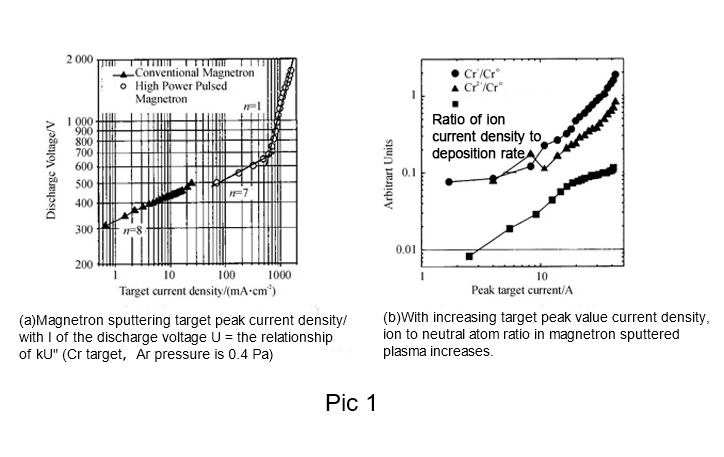

The elu ike pulsed magnetron sputtering Usoro na-eji elu elu usu ike (2-3 iwu nke ịdị ukwuu dị elu karịa ot magnetron sputtering) na ala pulse ọrụ okirikiri (0.5% -10%) iji nweta elu metal dissociation ọnụego (> 50%), nke na-ewepụtara site na magnetron sputtering e ji mara, dị ka e gosiri na pitity pensụl suttering e ji mara 1, dị ka e gosiri na pec 1. exponential nth ike nke mwepu voltaji U, I = kUn (n bụ mgbe niile metụtara cathode Ọdịdị, ndọta na ihe onwunwe). Na njupụta ike dị ala (obere voltaji) uru n na-abụkarị 5 ruo 15; na voltaji na-agbapụta na-arịwanye elu, njupụta dị ugbu a na njupụta ike na-abawanye ngwa ngwa, na elu voltaji uru n na-aghọ 1 n'ihi nkwụsị nke njide magnetik. Ọ bụrụ na njupụta ike dị ala, a na-ekpebi nkwụsị gas site na ion gas nke dị na ọnọdụ mwepu pulsed nkịtị; Ọ bụrụ na n'ịdị elu ike densities, nkezi nke metal ion na plasma na-abawanye na ụfọdụ ihe ịgbanwee, nke ahụ bụ na onwe-sputtering mode, ie The plasma na-nọgidere site ionization nke sputtered na-anọpụ iche irighiri na nke abụọ metal ion, na inert gas atọm dị ka Ar na-eji naanị na-amụnye na plasma, mgbe nke a sputtered metal azuoku na-ezubere iche na-ezubere iche na-ezubere iche. sputtered lekwasịrị n'okpuru omume nke magnetik na electric ubi iji nọgide na-enwe elu ugbu a mwepu, na plasma bụ ukwuu ionized metal ahụ. N'ihi na sputtering usoro nke kpo oku mmetụta na lekwasịrị anya, iji hụ na kwụsiri ike ọrụ nke lekwasịrị na ulo oru ngwa, ike njupụta ozugbo etinyere na lekwasịrị apụghị ịdị oke ibu, n'ozuzu kpọmkwem mmiri jụrụ na lekwasịrị ihe thermal conductivity kwesịrị ịbụ n'ihe banyere 25 W / cm2 n'okpuru, mmiri jụrụ oyi na-apụtachaghị ìhè, ezubere iche ihe thermal conductivity bụ ogbenye, ezubere iche ihe onwunwe kpatara site n'ikiri ala, ihe ezubere iche na-akpata site na ihe na-adịghị mma ma ọ bụ ihe mgbakasị ahụ nwere ike ịbụ ihe na-adịghị mma. ikpe ndị ọzọ nke njupụta ike nwere ike ịbụ naanị na 2 ~ 15 W / cm2 n'okpuru, dị n'okpuru ihe achọrọ nke njupụta ike dị elu. Enwere ike idozi nsogbu nke ikpo oke ọkụ nke ebumnuche site n'iji ike dị elu dị warara. Anders na-akọwapụta ike dị elu pulsed magnetron sputtering dị ka ụdị pulsed sputtering ebe oke ike njupụta karịrị nkezi ike njupụta site 2 ruo 3 iwu nke ịdị ukwuu, na lekwasịrị ion sputtering na-achị na sputtering usoro, na lekwasịrị sputtering atọm na-ukwuu dissociated.

No.2 The e ji mara elu ike pulsed magnetron sputtering mkpuchi nkwụnye ego

Nnukwu ike pulsed magnetron sputtering nwere ike iwepụta plasma nwere oke dissociation ọnụego na ike ion dị elu, ma nwee ike itinye nrụgide nhụsianya iji mee ka ion ebubo ahụ dịkwuo elu, na usoro ntinye mkpuchi mkpuchi na-agbaze site na oke ume ike, nke bụ nkà na ụzụ IPVD na-ahụkarị. Ike ion na nkesa nwere mmetụta dị oke mkpa na mkpuchi mkpuchi na arụmọrụ.

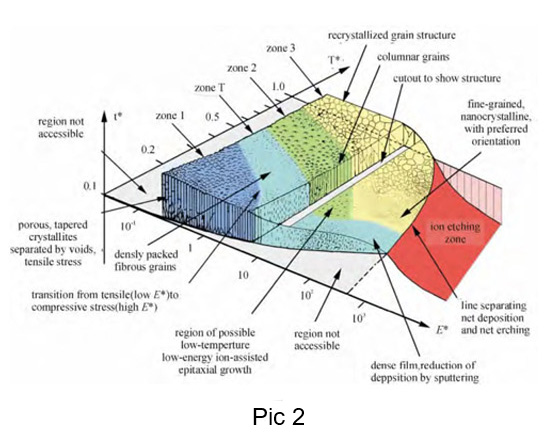

Banyere IPVD, dabere na ama Thorton structural region model, Anders tụrụ aro a bughi mpaghara ihe nlereanya nke na-agụnye plasma deposition na ion etching, gbasaa mmekọrịta dị n'etiti mkpuchi Ọdịdị na okpomọkụ na ikuku mgbali na Thorton structural region nlereanya na mmekọrịta dị n'etiti mkpuchi Ọdịdị, okpomọkụ na ion ike, dị ka e gosiri na foto 2. N'ihe banyere obere ike ion deposition mkpuchi ihe atụ nke Thorton nhazi usoro. Site na mmụba nke ọnọdụ okpomọkụ, mgbanwe site na mpaghara 1 (kristal ndị na-adịghị mma) na mpaghara T (kristal fiber na-acha ọkụ), mpaghara 2 (kristal kọlụm) na mpaghara 3 (mpaghara recrystallization); na mmụba nke ntinye ion ike, mgbanwe okpomọkụ site na mpaghara 1 gaa na mpaghara T, mpaghara 2 na mpaghara 3 na-ebelata. Enwere ike ịkwadebe kristal eriri dị elu na kristal columnar na obere okpomọkụ. Mgbe ike nke ion ndị a na-echekwa na-abawanye n'usoro nke 1-10 eV, bọmbụ na etching nke ions n'elu mkpuchi mkpuchi na-eme ka ọ dịkwuo elu ma na-abawanye ụba nke mkpuchi.

No.3 Nkwadebe nke ike mkpuchi oyi akwa site elu ike pulsed magnetron sputtering technology

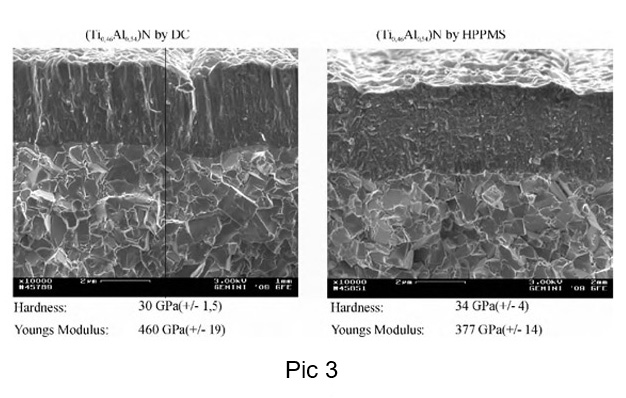

Ihe mkpuchi a kwadebere site na teknụzụ magnetron sputtering ike dị elu dị oke ọnụ, nwere akụrụngwa akụrụngwa ka mma yana nkwụsi ike dị elu. Dị ka e gosiri na foto 3, ihe mkpuchi TiAlN magnetron na-agbasa bụ ihe owuwu kristal kọlụm nwere ike nke 30 GPa na modul nke Young nke 460 GPa; mkpuchi HIPIMS-TiAlN bụ 34 GPa hardness ebe modul nke Young bụ 377 GPa; oke dị n'etiti ike siri ike na modul Young bụ ihe nleba anya siri ike nke mkpuchi. Isi ike dị elu na obere modul nke ntorobịa pụtara isi ike ka mma. Ihe mkpuchi HIPIMS-TiAlN nwere nkwụsi ike dị elu ka mma, yana usoro hexagonal AlN na-ebuli na mkpuchi TiAlN a na-ahụkarị mgbe ọgwụgwọ anneal okpomọkụ dị elu na 1,000 Celsius C maka awa 4. Ike nke mkpuchi na-ebelata na okpomọkụ dị elu, ebe mkpuchi HIPIMS-TiAlN na-anọgide na-agbanweghị mgbe ọgwụgwọ okpomọkụ gasịrị n'otu oge okpomọkụ na oge. HIPIMS-TiAlN mkpuchi nwekwara elu mmalite okpomọkụ nke elu okpomọkụ oxidation karịa uwe mkpuchi. Ya mere, mkpuchi HIPIMS-TiAlN na-egosi arụmọrụ dị mma na ngwa ngwa ịkpụ ngwa ngwa karịa ngwaọrụ ndị ọzọ mkpuchi nke PVD kwadebere.

Oge nzipu: Nov-08-2022