PRODUCT DESCRIPTION

With the rapid growth of the market demand for improving the wear resistance, lubrication, corrosion resistance and other properties of hard coatings, cathodic arc magnetic filtration ion coating equipment has become a highlight. The equipment adopts the most commonly used and effective 90 degree elbow circular section magnetic filter device, which can effectively remove large particles, so as to give full play to the advantages of cathodic arc ion coating technology. In the field of preparing DLC superhard coatings, especially in the field of preparing Ta-C coatings with many excellent physical and chemical properties, such as high hardness, low friction coefficient, heat conduction, insulation, UV absorption, radiation damage resistance, corrosion resistance, etc., the advantages are particularly significant. The average hardness of Ta-C coatings can reach up to about 63GPa.

The equipment can deposit Hybrid diamond-like carbon coatings such as Ta-C / AlTiN / AlCrN / TiCrAlN / TiAlSiN / CrN, which is suitable for micro drilling, milling cutters, taps, rod-shaped cutters, auto parts, medical devices and other fields.

The laser Raman spectrum test results, the Raman spectrum of Cr transition layer on the surface of high-speed steel:

Sample 20210122, Gaussian fitting of Raman test results (ID/IG=0.224, sp3 content is high enough):

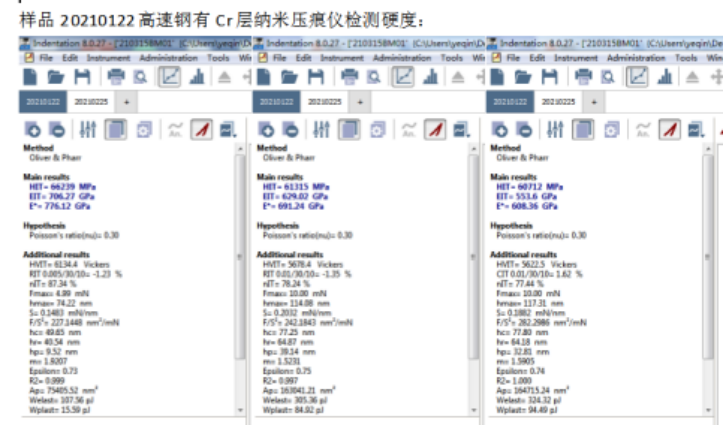

According to the hardness test results of Nano indentation instrument, the average hardness of sample 20210122 is 62.7GPa:

Optional models

| MFA0605 |

| φ600*H500(mm) |