1) Plasma surface modification mainly refers to certain modifications of paper, organic films, textiles, and chemical fibers. The use of plasma for textile modification does not require the use of activators, and the treatment process does not damage the characteristics of the fibers themselves. It can improve the water absorption, hydrophobicity, oil repellency, adhesion, light reflection, breathability, antistatic properties, friction coefficient, biocompatibility of textiles, and has the characteristics of good hand feel and easy coloring. It is also environmentally friendly and has great economic benefits.

2) Plasma surface modification can be applied to various organic films, such as PE, PP, PS, CPE, PTFE, PA6, PA66, NR, PVA, PMMA, poly4-methylpentene, and polyisobutylene. Plasma irradiation can cut off the covalent bond of the organic film, and increase the film polarity, adhesion, light reflection, permeability, antistatic property, etc. In the coating process of flexible film rolls, anode layer ion sources are often used to bombard organic films with argon ions, which can significantly improve the film substrate bonding force. Plasma surface modification has improved the adhesion between PET and coatings, playing a significant role in laser printing.

3) In the field of medicine, plasma treatment can improve biocompatibility and the hydrophilicity, breathability, and blood solubility of biomaterials, which can make biomedical materials such as artificial blood vessels and hemodialysis films widely used. Treating bacterial culture dishes with plasma is beneficial for cell growth.

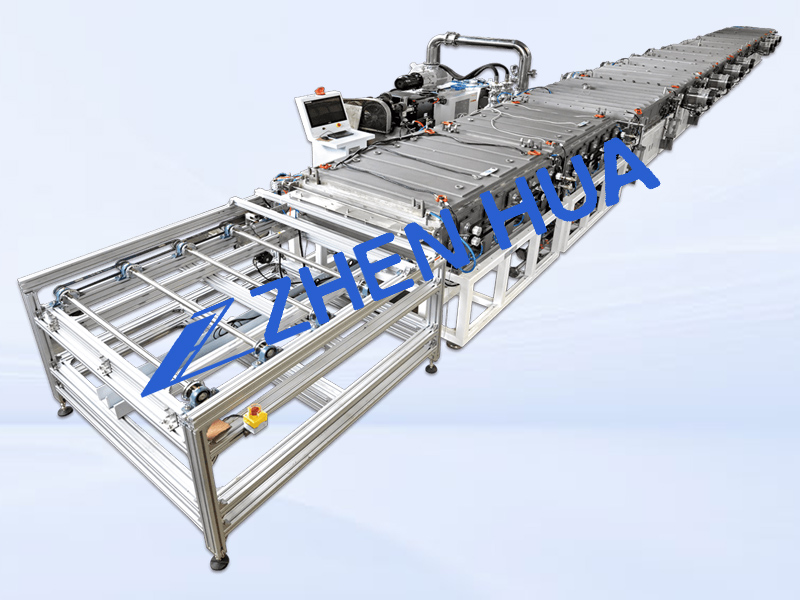

–This article was released by Guangdong Zhenhua, a vacuum coating machine manufacturer

Post time: May-27-2023