① Good controllability and repeatability of film thickness

Whether the film thickness can be controlled at a predetermined value is called film thickness controllability. The required film thickness can be repeated for many times, which is called film thickness repeatability.Because the discharge current and target current of vacuum sputtering coating can be controlled separately. Therefore, the thickness of sputtered film is controllable, and the film with predetermined thickness can be deposited reliably. In addition, the sputter coating can obtain a film with uniform thickness on a large surface.

② Strong adhesion between film and substrate

The energy of sputtered atoms is 1-2 orders of magnitude higher than that of evaporated atoms. The energy conversion of the high-energy sputtered atoms deposited on the substrate is much higher than that of the evaporated atoms, which generates higher heat and enhances the adhesion between the sputtered atoms and the substrate. In addition, some high-energy sputtered atoms produce different degrees of injection, forming a pseudodiffusion layer on the substrate. In addition, the substrate is always cleaned and activated in the plasma region during the film forming process, which removes the sputtering atoms with weak adhesion, and purifies and activates the substrate surface. Therefore, the sputtered film has strong adhesion to the substrate.

③ New material film different from target can be prepared

If reactive gas is introduced during sputtering to make it react with the target, a new material film completely different from the target can be obtained. For example, silicon is used as the sputtering target, and oxygen and argon are put into the vacuum chamber together. After sputtering, SiOz insulating film can be obtained. Using titanium as the sputtering target, nitrogen and argon are put into the vacuum chamber together, and the phase TiN gold-like film can be obtained after sputtering.

④ High purity and good quality of film

Since there is no crucible component in the sputtering film preparation device, the components of the crucible heater material will not be mixed in the sputtering film layer. The disadvantages of sputtering coating are that the film forming speed is slower than that of evaporation coating, the substrate temperature is higher, it is easy to be affected by impurity gas, and the device structure is more complex.

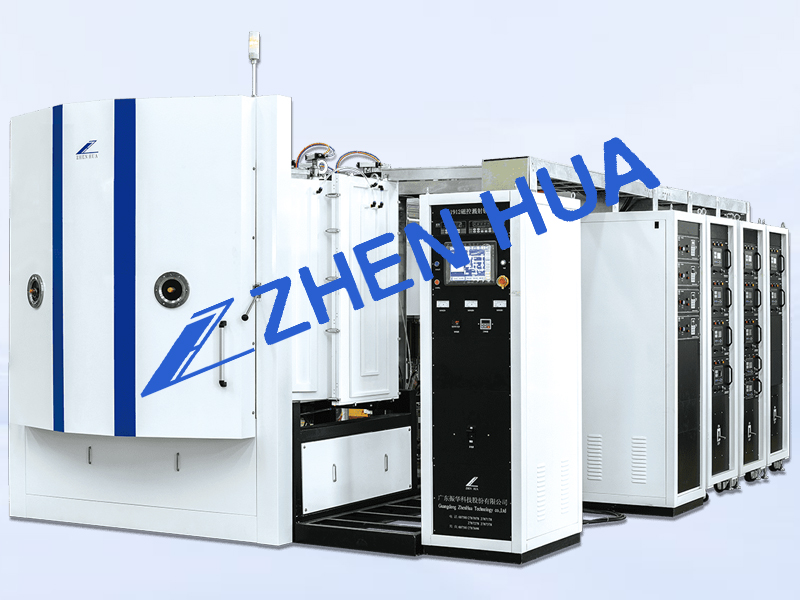

This article is published by Guangdong Zhenhua, a manufacturer of vacuum coating equipment

Post time: Mar-09-2023