The rapid development of vacuum coaters in today’s era has enriched the types of coaters. Next, let’s list the classification of coating and the industries to which the coating machine is applied.

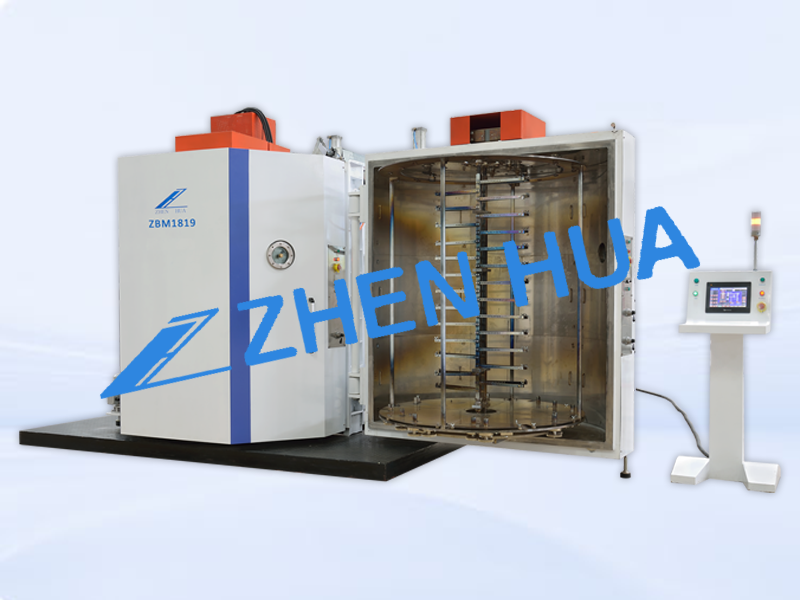

First of all, our coating machines can be divided into decorative coating equipment, electron beam evaporation coating equipment, continuous coating production line, functional coating equipment and winding coating equipment. The wide variety of coating machines also means that they are applied in a wide range of industries.

Evaporative coating equipment, one of the decorative coating equipment, can be used to process ABS, PS, PC, PP, PVC, TPU, nylon, metal, glass, ceramic and other materials. It has been widely used in mobile phone plastic structural parts, smart home, digital products, cosmetics packaging, handicrafts, toys, wine packaging, electronic components and other products.

Electron beam evaporation coating equipment: This equipment is mostly used in various compounds and metal plating materials, and can be used to prepare multi-layer precision optical films, such as AR film, long wave pass, short wave pass, brightening film, AS/AF film, IRCUT, color film system, gradient film system, etc. It has been widely used in mobile phone glass covers, cameras, glasses, optical lenses, swimming goggles, ski goggles, PET films, PMMA, optical magnetic films, anti-counterfeiting, cosmetics and other products. People with such needs can certify this coating equipment.

Continuous coating production line, the equipment is mainly used in automobile industry, such as car logo coating, automobile plastic trim, electronic product shell and other products. Its advantages are that the coating chamber of the coating line is in a high vacuum state for a long time, with less impurity, high film purity and good refractive index. It is equipped with a fully automatic Speedflow closed-loop control system to improve the deposition rate of the film layer. The production process is monitored in the whole process, and it is convenient to quickly track the production defects. The equipment is highly automated. It can cooperate with the manipulator to complete the process, reducing the labor cost.

Functional coating coating equipment, this equipment is fingerprint proof series, such as bathroom hardware, ceramic parts, mobile phone glass cover, middle frame and keys, digital products, cameras, touch screens, clocks, watches, jewelry, sunglasses, swimming goggles and other products. The film has good hydrophobicity, high stability, excellent antifouling, waterproof and wear-resistant effects, so it is also a good choice.

The last roll to roll coating equipment, which is mainly used in flexible film materials such as PET film and conductive cloth, is widely used in mobile phone decorative film, packaging film, EMI electromagnetic screen shielding film, ITO transparent film and other products.

Post time: Feb-10-2023