Welcome to Guangdong Zhenhua Technology Co.,Ltd.

News

-

What are the requirements of vacuum coating process on the application environment

The vacuum coating process has strict requirements for the application environment. For the conventional vacuum process, its main requirements for vacuum sanitation are: there is no accumulated pollution source on the parts or surface of the equipment in the vacuum, the surface of the vacuum cham...Read more -

What is the Working Principle of Ion Plating machine

Ion coating machine originated from the theory proposed by D.M. Mattox in the 1960s, and corresponding experiments began at that time; Until 1971, Chambers and others published the technology of electron beam ion plating; The reactive evaporation plating (ARE) technology was pointed out in the Bu...Read more -

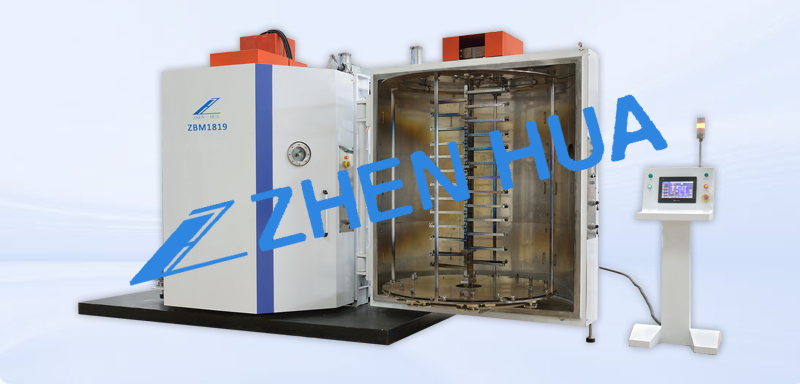

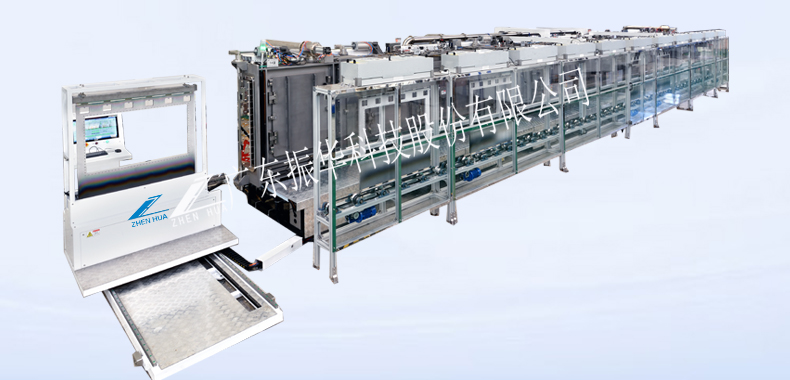

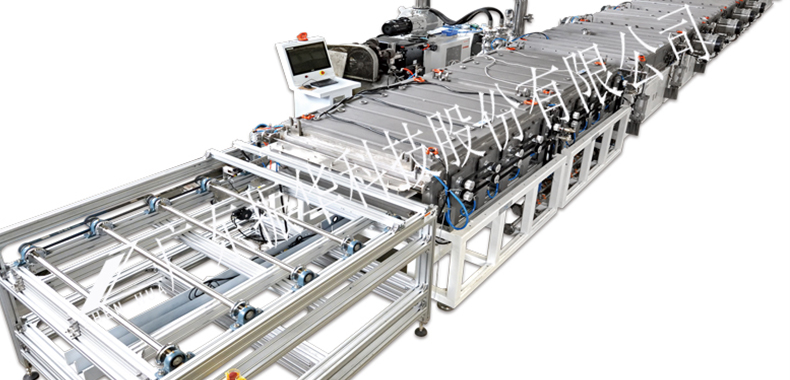

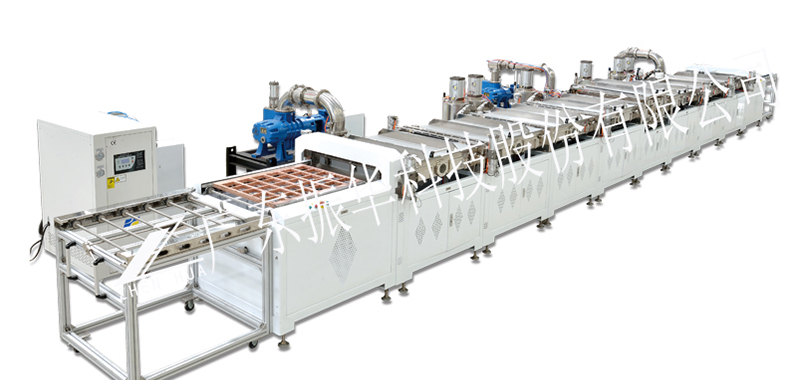

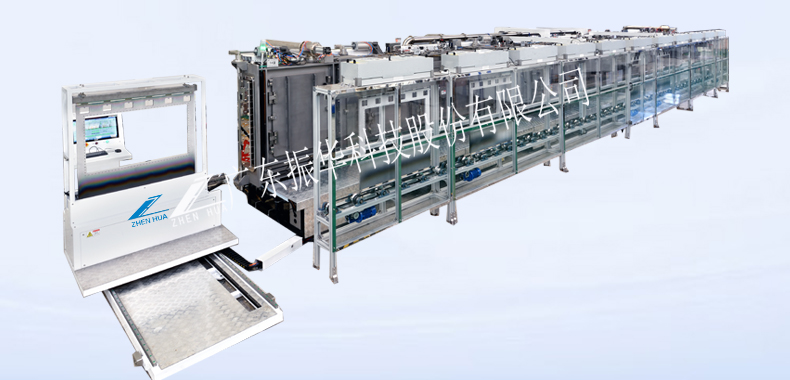

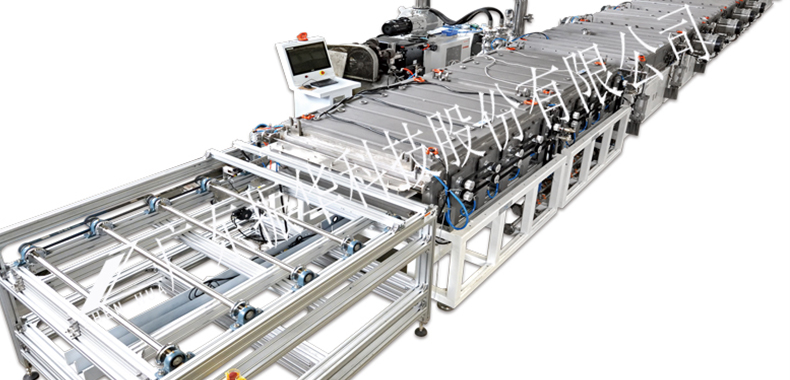

Classification and application of vacuum coating equipment

The rapid development of vacuum coaters in today’s era has enriched the types of coaters. Next, let’s list the classification of coating and the industries to which the coating machine is applied. First of all, our coating machines can be divided into decorative coating equipment, ele...Read more -

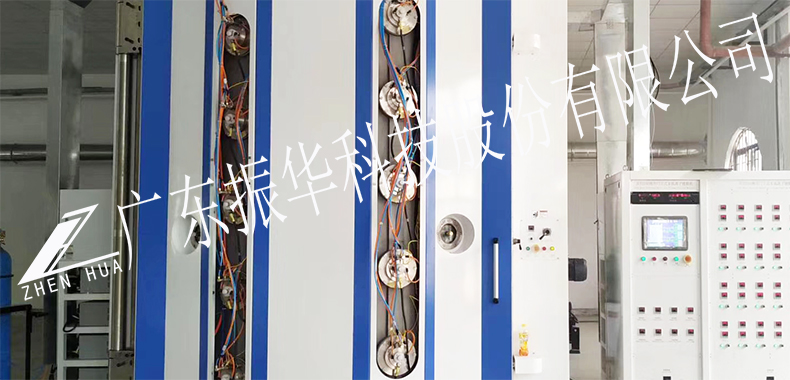

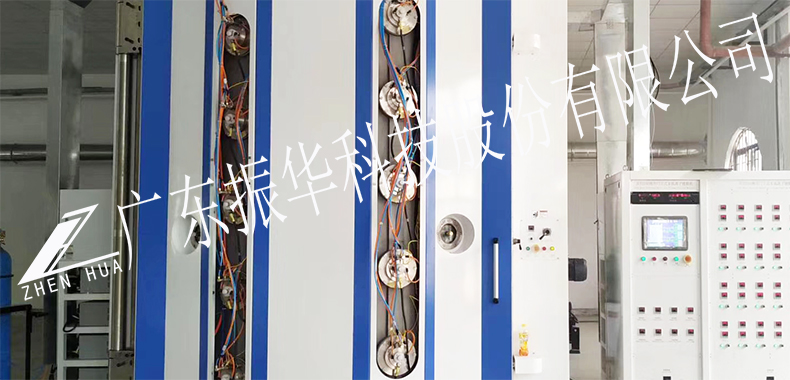

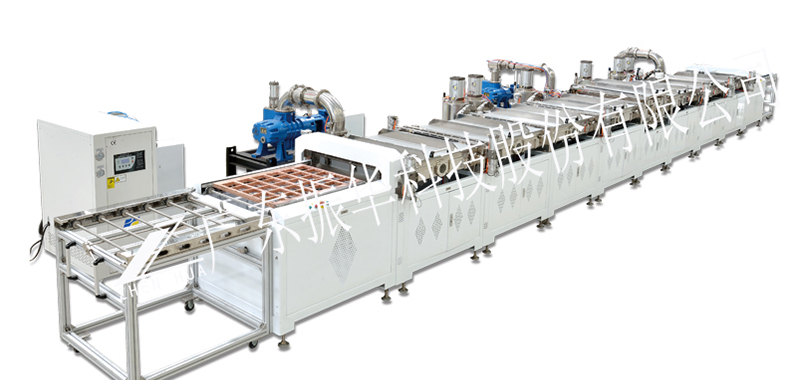

Brief introduction and advantages of magnetron sputtering coating equipment

Magnetron sputtering principle: electrons collide with argon atoms in the process of accelerating to the substrate under the action of electric field, ionizing a large number of argon ions and electrons, and electrons fly to the substrate. The argon ion accelerates to bombard the target material ...Read more -

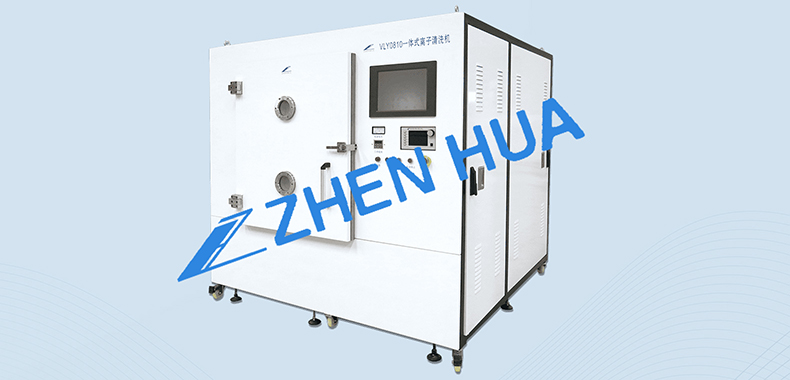

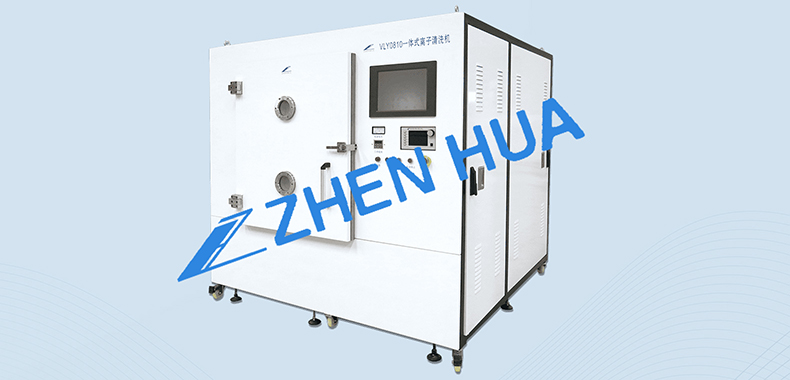

Advantages of vacuum plasma cleaning machine

1. Vacuum plasma cleaning machine can prevent users from generating harmful gas to human body during wet cleaning and avoid washing things. 2. The cleaning object is dried after plasma cleaning, and can be sent to the next process without further drying treatment, which can achieve the processing...Read more -

What is PVD coating technology

PVD coating is one of the main technologies for preparing thin film materials The film layer endows the product surface with metal texture and rich color, improves wear resistance and corrosion resistance, and extends the service life. Sputtering and vacuum evaporation are the two most mainstream...Read more -

99zxc.Plastic optical component coating application

At present, the industry is developing optical coatings for applications such as digital cameras, bar code scanners, fiber optic sensors and communication networks, and biometric security systems. As the market grows in favor of low-cost, high-performance plastic optical...Read more -

How to remove the film layer of coated glass

Coated glass is divided into evaporative coated, magnetron sputtering coated and in-line vapor deposited coated glass. As the method of preparing the film is different, the method of removing the film is also different. Suggestion 1, Using hydrochloric acid and zinc powder for polishing and rubb...Read more -

The few problems of the vacuum system should not be ignored.

1, When the vacuum components, such as valves, traps, dust collectors and vacuum pumps, are connected to each other, they should try to make the pumping pipeline short, the pipeline flow guide is large, and the diameter of the conduit is generally not smaller than the diameter of the pump port, w...Read more -

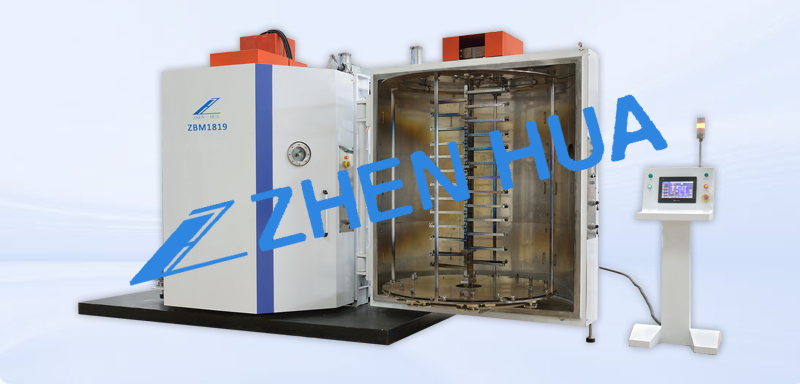

What is vacuum ion coating technology

1、The principle of vacuum ion coating technology Using vacuum arc discharge technology in a vacuum chamber, arc light is generated on the surface of the cathode material, causing atoms and ions to form on the cathode material. Under the action of electric field, the atom and ion beams bombard th...Read more -

How to choose a vacuum coating equipment supplier

At present, the number of domestic vacuum coating equipment manufacturers is increasing, there are hundreds of domestic and many foreign countries, so how to choose a suitable supplier among so many brands? How to choose the right vacuum coating equipment manufacturer for yourself? This depends o...Read more -

The difference between vacuum coating and wet coating

Vacuum coating has obvious advantages compared to wet coating. 1、Wide selection of film and substrate materials, the thickness of the film can be controlled to prepare functional films with various functions. 2、The film is prepared under vacuum condition, the environment is clean and the film ...Read more -

Role and performance optimization of cutting tool coatings

Cutting tool coatings improve the friction and wear properties of cutting tools, which is why they are essential in cutting operations. For many years, surface processing technology providers have been developing customized coating solutions to improve cutting tool wear resistance, machining effi...Read more -

Gear coating technology

PVD deposition technology has been practiced for many years as a new surface modification technology, especially vacuum ion coating technology, which has gained great development in recent years and is now widely used in the treatment of tools, molds, piston rings, gears and other components. The...Read more -

Current application situation of vacuum semiconductor coating

As we all know, the definition of semiconductor is that it has a conductivity between dry conductors and insulators, resistivity between metal and insulator, which is usually at room temperature is within the range of 1mΩ-cm ~ 1GΩ-cm.In recent years, vacuum semiconductor coating in the major semi...Read more