Plasma direct polymerization process

The process of Plasma polymerization is relatively simple for both internal electrode polymerization equipment and external electrode polymerization equipment, but parameter selection is more important in Plasma polymerization, because parameters have a greater impact on the structure and performance of polymer films during Plasma polymerization.

The operation steps for direct plasma polymerization are as follows:

(1) Vacuuming

The background vacuum of polymerization under vacuum conditions should be pumped to 1.3×10-1Pa. For polymerization reactions that require special requirements for controlling oxygen or nitrogen content, the background vacuum requirement is even higher.

(2) Charge reaction monomer or mixed gas of carrier gas and monomer

The vacuum degree is 13-130Pa. For Plasma polymerization requiring work, appropriate flow control mode and flow rate shall be selected, generally 10.100mL/min. In plasma, monomer molecules are ionized and dissociated by bombardment of energetic particles, resulting in active particles such as ions and active genes. The active particles activated by plasma can undergo Plasma polymerization at the interface of gas phase and solid phase. The monomer is the source of precursor for Plasma polymerization, and the input reaction gas and monomer shall have certain purity.

(3) Selection of excitation power supply

Plasma can be generated using DC, high-frequency, RF, or microwave power sources to provide a plasma environment for polymerization. The selection of power supply is determined based on the requirements for the structure and performance of the polymer.

(4) Selection of discharge mode

For polymer requirements, Plasma polymerization can choose two discharge modes: continuous discharge or pulse discharge.

(5) Selection of discharge parameters

When conducting Plasma polymerization, discharge parameters need to be considered from plasma parameters, polymer properties and structure requirements. The magnitude of the applied power during polymerization is determined by the volume of the vacuum chamber, electrode size, monomer flow rate and structure, polymerization rate, and polymer structure and performance. For example, if the reaction chamber volume is 1L and RF Plasma polymerization is adopted, the discharge power will be in the range of 10~30W. Under such conditions, the plasma generated can aggregate to form a thin film on the surface of the workpiece. The growth rate of Plasma polymerization film varies with power supply, monomer type and flow rate, and process conditions. Generally, the growth rate is 100nm/min~1um/min.

(6) Parameter measurement in Plasma polymerization

The plasma parameters and process parameters to be measured in Plasma polymerization include: discharge voltage, discharge current, discharge frequency, Electron temperature, density, reaction group type and concentration, etc.

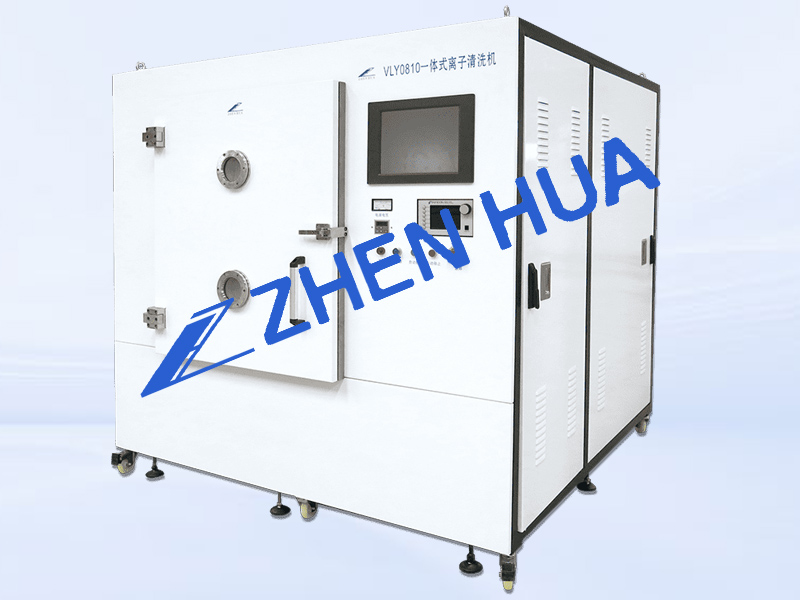

——This article was released by Guangdong Zhenhua Technology, a manufacturer of optical coating machines.

Post time: May-05-2023