1.Demand change in the era of smart cars

With the continuous development of smart car technology, smart mirrors, as an important part of automotive human-machine interaction, have gradually become the industry standard. From the traditional simple reflective mirror to today’s intelligent rear-view mirror integrated with a variety of functions, its role is not only limited to provide driving vision expansion, but also the core terminal of intelligent driving, safety monitoring, vehicle information display and other systems. The application scenarios of automotive smart mirrors put forward high requirements for optical coating technology. In order to ensure the clarity, stability and durability of mirrors during driving, mirrors need to have excellent anti-reflective, anti-glare, waterproof and anti-fouling characteristics. These features depend on the high precision and multi-layer processing capabilities of the coating process. Meanwhile, with the arrival of the TWh era (gigawatt-hour market), the automotive smart mirror market has put forward higher requirements for the production efficiency, yield and cost control ability of coating equipment.

2. Industry pain point: the technical challenges of intelligent rear-view mirror coating

However, the current coating process for smart mirrors is still facing a lot of technical difficulties, mainly including the following aspects:

① Low production efficiency: the existing traditional coating technology often requires a long coating time, resulting in slow production speed. In mass production, this low speed will significantly reduce the overall production efficiency, unable to meet market demand.

② film performance is not stable: in mass production, the consistency and stability of the film is the key, and traditional equipment is often difficult to maintain the uniformity of the coating, resulting in unstable film performance, affecting the quality and service life of the final product.

② low infrared transmittance: smart mirrors are often integrated with infrared cameras, thermal imaging functions, which requires coating materials with higher infrared transmittance, in order to better support the image display at night or in harsh environments. Existing coating technology is often unable to balance the reflection and transmission rate, affecting the imaging effect.

④ High energy consumption: traditional coating equipment usually consumes more energy and has low productivity, especially in mass production, resulting in high energy consumption and limiting the promotion of mass production.

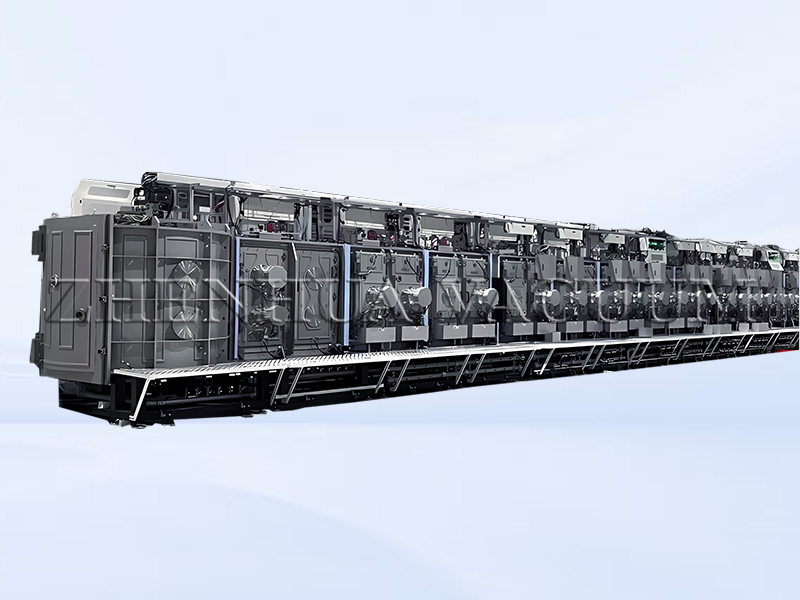

3.Zhenhua Automotive Intelligent Rearview Mirror Coating Solution–Large Vertical Super Multilayer Optical Coating Production Line

Aiming at the pain points of the current intelligent rearview mirror coating technology, Zhenhua’s large-scale vertical super-multilayer optical coating production line came into being, becoming a key solution to break through the bottleneck of the industry and improve the production efficiency and product performance. With its excellent technical advantages, the production line has not only successfully solved key technical problems in the coating process, such as the optimisation of infrared transmittance, high energy consumption and fluctuation of film performance, but also demonstrated remarkable results in significantly improving production efficiency and effectively reducing energy consumption.

–This article is released by vacuum coating machine manufacturer Guangdong Zhenhua

Post time: Dec-26-2024