With the continuous progress of automotive technology, the market demand for automotive center control screen continues to grow. Currently automotive center control screen is no longer a simple information display terminal, but a blend of multimedia entertainment, navigation, vehicle control, intelligent connectivity and other functions in one. Consumers are also increasingly demanding for the central control screen, not only expect it to have a high resolution, vivid color performance and fast response speed, but also required in different lighting conditions can be clearly visible, and has good durability and scratch resistance.

The development of automotive center control screen market is full of opportunities, but also faces a number of challenges. Its performance is closely related to the coating technology. Coating technology is a surface treatment technology used to enhance the performance of the material, enhance the hardness, corrosion resistance or optical properties. At present, there are still some pain points in the automotive center control screen coating technology, restricting the further improvement of the performance of the center control screen. For example, the coating quality is not stable, the film layer is easy to fall off, blistering, discoloration, affecting the appearance and performance; low visible light transmission rate, the screen display blurred, affecting the user experience; hardness is not enough, easy to appear scratches, reducing the aesthetics and service life; production efficiency is low, increasing costs, extending the delivery cycle, affecting the competitiveness of the market.

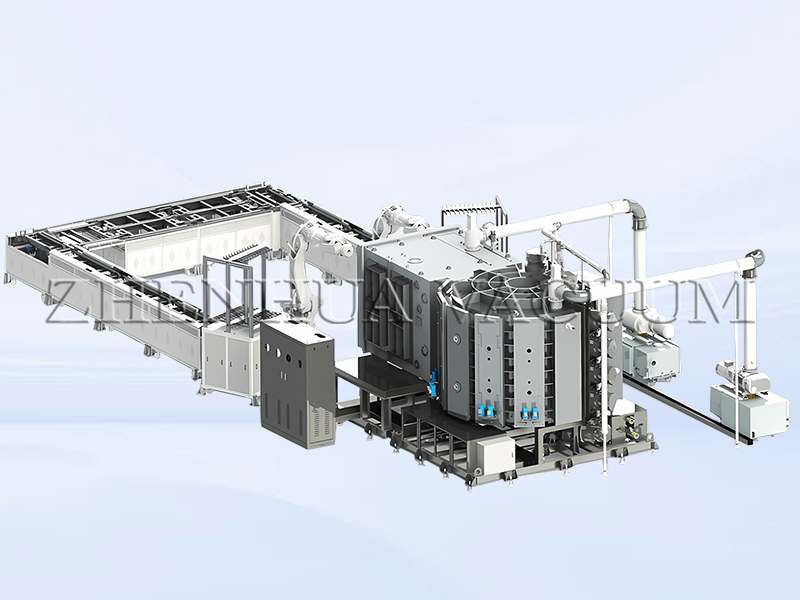

In response to the challenges encountered in the practicality and production efficiency of automotive center control screen, Zhenhua SOM-2550 continuous magnetron sputtering optical coating equipment came into being, aiming at solving the industry’s problems and providing an efficient and stable coating solution for the automotive center control screen market. The solution not only significantly improves the stability and quality of the coating process, but also essentially improves the practical performance of the center control screen, while significantly improving the production efficiency.

Zhenhua automobile center control screen coating solution – SOM-2550 continuous magnetron sputtering optical coating equipment

1. Superior coating performance to meet the high standard demand of the market.

The equipment adopts magnetron sputtering coating technology, with uniform film layer and strong adhesion, which effectively improves the overall performance and durability of the center control panel. The visible light transmission rate of the coated film is up to 99%, which ensures that the center control screen can present clear and bright images under various lighting conditions, greatly enhancing the user’s visual experience. The equipment can be plated with super-hard AR + AF, with a hardness of up to 9H, which effectively enhances the scratch-resistant performance of the center control screen, prolongs the service life of the product, and maintains the aesthetics and integrity of the screen.

2. High degree of automation, realizing cost reduction and efficiency increase

The equipment is equipped with robot to load and unload the substrate. Equipped with separable inlet and outlet chambers, the inlet and outlet can be fully automated, feeding and discharging at the same time, to ensure the stability of production efficiency and product quality, and provide strong support for the enterprise to achieve cost reduction and efficiency.

3. High production efficiency and large loading capacity

The equipment has high production efficiency, and the default supporting 24 pieces substrate, the effective coating area is up to about 8 square meters. Meet the market demand for mass production of automotive center control screen, reduce production costs and improve market competitiveness.

Application scope: mainly produce AR/NCVM+DLC+AF, and automotive center control screen, intelligent rearview mirror, car display/touch screen cover glass, camera, super hard AR, IR-CUT and other filters, face recognition and other products.

Application: Mainly produce AR/NCVM+DLC+AF, as well as automobile center control screen, intelligent rearview mirror, car display/touch screen cover glass, camera, super hard AR, IR-CUT and other filters, face recognition and other products.

–This article is released by vacuum coating machine manufacturer Guangdong Zhenhua

Post time: Oct-25-2024