Vacuum ion coating (referred to as ion plating) is the United States in 1963 Somdia company D.M. Mattox proposed, the 1970s has been the rapid development of a new surface treatment technology. It refers to the use of evaporation source or sputtering target in a vacuum atmosphere so that the film material evaporation or sputtering, evaporation or sputtering out of a part of the particles in the gas discharge space ionized into metal ions.

These particles are deposited on the substrate under the action of electric field to generate a thin film process.

Vacuum ion plating of many kinds, usually according to the membrane material to produce the ion source will be divided into two types: evaporation source type ion plating and sputtering target type ion plating. The former is evaporated by heating the film material to produce metal vapors, so that it is partially ionized into metal vapors and high-energy neutral atoms in the space of the gas discharge plasma, through the role of the electric field to reach the substrate to generate thin films; the latter is the use of high-energy ions (eg, Ar +) on the surface of the film material bombardment to make the sputtering out of the particles through the space of the gas discharge ionized into ions or high-energy neutral atoms, to reach the surface of the substrate and generate the film.

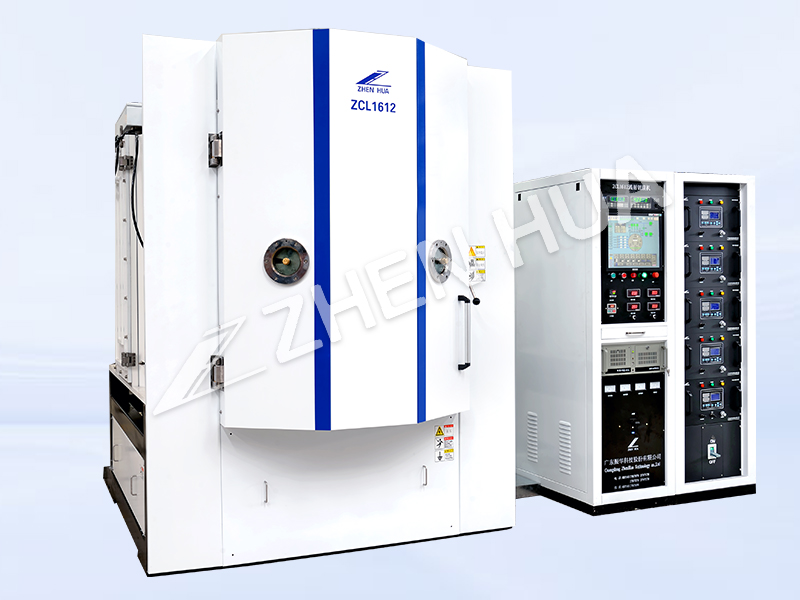

–This article is released by vacuum coating machine manufacturer Guangdong Zhenhua

Post time: Mar-07-2024