No.1 New Challenges Under the Water-based Paint Replacement: The “Repulsion Effect” Between Polymers and Coatings

Traditional solvent-based paints, due to their severe VOC emissions, can no longer meet the environmental requirements of regulations such as the EU REACH Regulation. The automotive interior coating process is rapidly transitioning to water-based paints. However, while water-based paints offer significant environmental advantages, they expose a critical flaw—these polymers (e.g., ABS, PP, commonly used in automotive interiors) have low surface energy, resulting in poor wettability and insufficient adhesion of water-based paints. This can lead to issues such as coating delamination and reduced weather resistance. Particularly for irregularly shaped interior components (e.g., curved dashboards, 3D door trim strips), conventional surface treatment methods struggle to achieve uniform modification, further reducing production yield.

No.2 Zhenhua’s Innovative Solution: Reshaping Material Surface Properties, Empowering Water-based Paint Coating

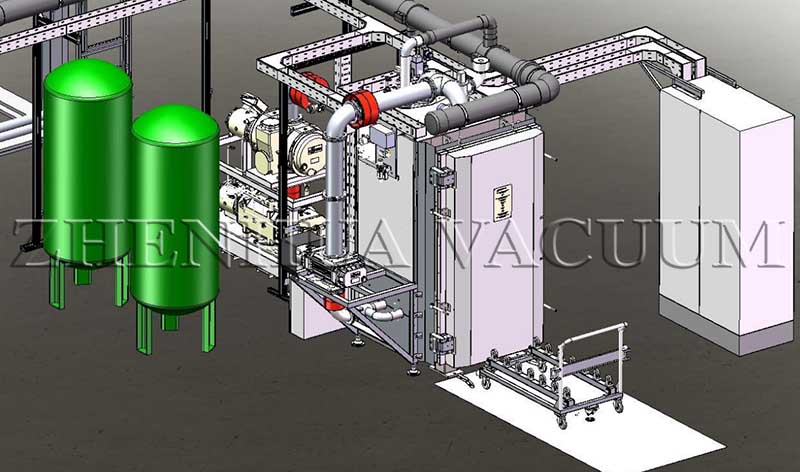

Addressing this industry pain point, Zhenhua Vacuum has independently developed vacuum Plastic part nitrogen fluorination treatment equipment, helping automotive component manufacturers overcome the bottleneck of insufficient water-based paint adhesion and providing efficient, eco-friendly pre-coating treatment solutions.

Equipment Advantages:

1.Innovative Surface Modification Technology, Enhancing Water-based Paint Adhesion

Utilizing proprietary nitrogen fluorination surface modification technology, precise gas-solid phase reactions reconstruct the molecular structure of plastic surfaces, endowing them with excellent hydrophilic properties. This enables water-based paints to wet more uniformly and adhere firmly, completely resolving the issue of poor bonding between water-based paints and polymers.

2.Comprehensive Performance Optimization: From Single Adhesion to Multi-dimensional Performance Enhancement

After treatment with the plastic surface nitrogen fluorination machine, the chemical stability of plastic surfaces is significantly improved, offering robust barrier properties that effectively resist external environmental erosion. Additionally, the treated surfaces exhibit excellent tolerance to chemical solvents, water vapor, odor gases, and microbial contaminants, significantly enhancing the long-term stability and service life of automotive interior components.

3.Precision Coating Control, Tackling Irregular Shape Challenges

Equipped with an advanced coating control system, the equipment ensures precise control over key parameters such as film thickness and uniformity. Through flexible and adjustable coating process parameters, it enables customized treatment based on the unique shapes and structures of irregular workpieces, ensuring uniform and efficient surface modification and providing reliable assurance for high-quality processing of complex geometries.

4.Wide Application Adaptability, Meeting Diverse Needs

By offering customized solutions for various industries, the technology significantly expands the application of polymer materials, driving comprehensive upgrades in product quality and performance:

Automotive Industry: Enhances the quality of interior and exterior plastic components, meeting stringent EU environmental standards.

Chemical Industry: Improves the corrosion resistance and stability of plastic parts in chemical equipment.

Electronics Industry: Boosts the stability and protective properties of plastic housings for electronic components.

Packaging Industry: Optimizes the barrier properties and printability of packaging films.

Film Production Industry: Vacuum nitrogen fluorination-treated plastic films exhibit optimized surface properties, enabling the production of high-performance functional films.

No.3 Conclusion

As the global automotive industry advances toward a green manufacturing era characterized by low VOC and low carbon emissions, the environmental upgrade of coating processes has become an irreversible trend. Zhenhua Vacuum’s vacuum nitrogen fluorination treatment equipment, with its innovative surface modification technology, with its exceptional environmental performance and broad applicability), Zhenhua Vacuum’s technology redefines the strategic value of surface engineering, providing automotive manufacturers with efficient and sustainable solutions.

–This article is published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Mar-25-2025