HUD (Head-Up Display) projects critical driving information (e.g., speed, navigation, ADAS warnings) onto the windshield or a dedicated display, allowing drivers to access data without looking down, thereby enhancing driving safety and convenience. To achieve clear and stable display performance, optical coating technology is essential. Different functional coatings deliver distinct effects:

High-reflection coating (HR coating): Increases reflectivity, enhancing HUD projection brightness and clarity.

Anti-reflection coating (AR coating): Reduces light reflection, improving display sharpness.

Hard coating: Enhances surface abrasion resistance, extending service life.

Conductive coating: Enables anti-fog, anti-static, and other functional modules.

Currently, HUD have expanded from luxury vehicles to mid-range models, becoming a standard feature in smart cars. With sustained market demand, traditional coating equipment faces challenges such as low productivity, limited capacity, and insufficient automation, leading to capacity shortages and high costs—key bottlenecks hindering the HUD supply chain.

Zhenhua Vacuum has innovated an HUD vacuum coating solution, focusing on production efficiency and automation. Integrating high-precision layer control, intelligent loading/unloading systems, real-time process optimization, and adaptive production regulation, this solution overcomes industry pain points in throughput, consistency, and energy efficiency, empowering automotive component manufacturers to achieve high-yield mass production and cost optimization.

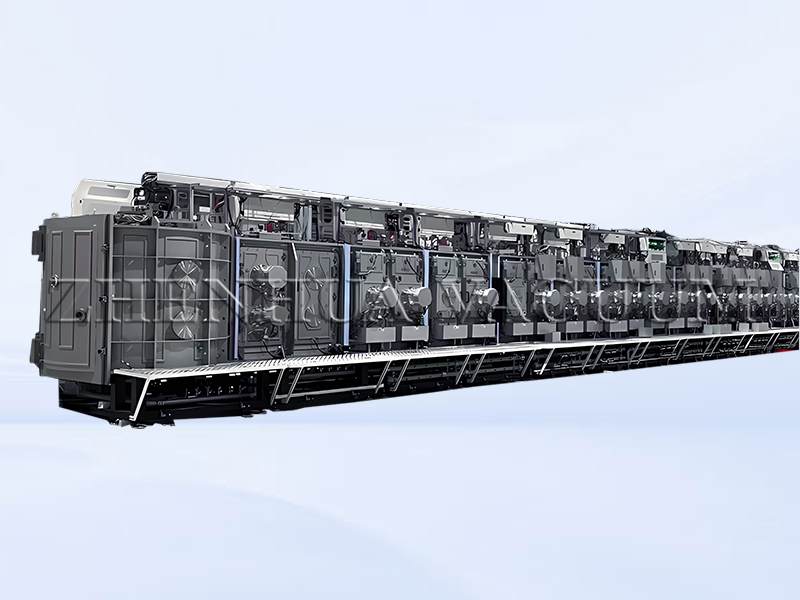

Zhenhua Vacuum Large Plate Optical Coating Inline Coater

Through iterative innovation, Zhenhua Vacuum Large Plate Optical Coating Inline Coater achieves breakthroughs in productivity (up to 50 m²/h) and automation. Key features include:

Robotic arm integration for fully automated workflow, ensuring efficiency and stability.

Low-energy vacuum system optimization, reducing operational costs without compromising output.

Multi-layer optical coatings (up to 14 layers) with exceptional uniformity and repeatability, meeting high-standard optical requirements.

Equipment advantages:

Supports mass production of oversized optical glass (2m x 3m).

High automation: Robotic arms enable seamless inter-process flow.

High throughput, low energy consumption: Max output of 50 m²/h.

Superior coating performance: Multi-layer precision coatings (up to 14 layers) with excellent reproducibility.

Applications:

Head-up display(HUD); Smart rearview mirror; Automotive center console panel; Touch screen glass cover; Camera lense; Optical lense

Zhenhua Vacuum empowers automotive component manufacturers to overcome capacity and process bottlenecks with its high-efficiency, stable, and intelligent coating production solutions, providing robust support for the rapid development of the HUD industry.

–This article is published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Apr-02-2025