Welcome to Guangdong Zhenhua Technology Co.,Ltd.

Industry News

-

Applications of diamond like carbon films

(1) cutting tool field DLC film used as a tool (such as drills, milling cutters, carbide inserts, etc.) coating, can improve tool life and tool edge hardness, reduce sharpening time, but also has a very low friction factor, low adhesion and excellent wear resistance. Therefore, DLC film tools sho...Read more -

Coating technology in CdTe solar cells

Thin-film solar cells have always been the industry’s research hotspot, several conversion efficiency can reach more than 20% of thin-film battery technology, including cadmium telluride (CdTe) thin-film battery and copper indium gallium selenide (CICS, Cu, In, Ga, Se abbreviation) thin-fil...Read more -

Optical thin films in projection display products

Almost all typical optical films are used in liquid crystal projection display systems. A typical LCD projection display optical system contains a light source (metal halide lamp or high pressure mercury lamp), an illumination optical system (including the light system and polarization conversion...Read more -

Hot cathode enhancement for magnetron sputtering

The tungsten filament is heated to a high temperature that emits hot electrons to emit a high-density electron stream, and at the same time an accelerating electrode is set to accelerate the hot electrons into a high-energy electron stream. High-density, high-energy electron flow can be more chlo...Read more -

Exploring the Process and Importance of Diffusion Pump Oil Change

As technology continues to advance, the need for efficient vacuum systems becomes crucial. One crucial component of such systems is the diffusion pump, which plays a vital role in maintaining the vacuum levels required for various industrial applications. To ensure efficient and reliable function...Read more -

Vacuum Ion Tools: Launch of High Quality PVD Hard Surface Coating Machine

In this advanced technology, companies are striving to meet the growing needs of consumers by providing high-performance products. Vacuum ion tools have become an industry game changer when it comes to surface coatings. With their superior quality and precision, they enable companies to achieve s...Read more -

Lab Vacuum Coating Equipment: Revolutionizing the Research Industry

Lab vacuum coating equipment, also known as vacuum deposition systems, are revolutionizing the way researchers conduct experiments and develop new materials. This sophisticated technology allows scientists to precisely coat materials with thin layers of substances such as metals, ceramics, and po...Read more -

Optical lens films: revolutionizing the visual world

In today’s fast-paced, technologically advanced world, we rely heavily on electronic devices such as smartphones, tablets, and laptops. These devices have become an important part of our lives, providing information and entertainment with just a few taps. Hidden behind the screens of these ...Read more -

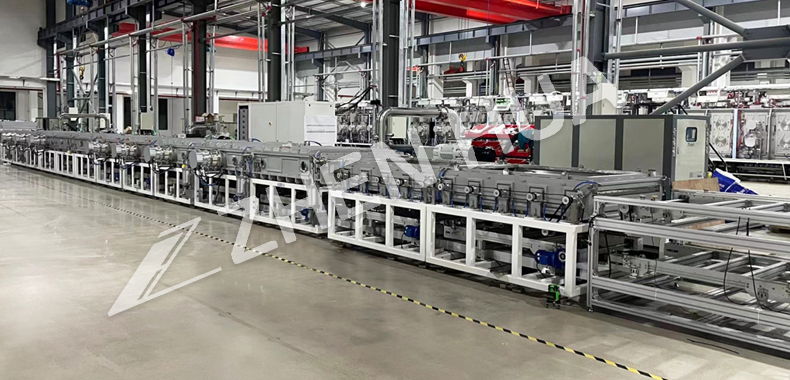

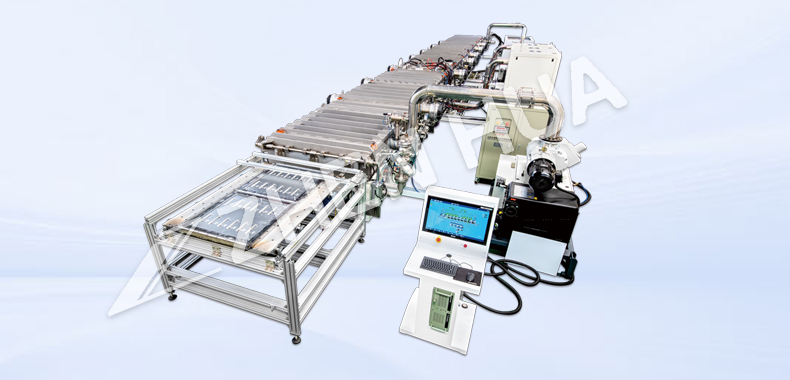

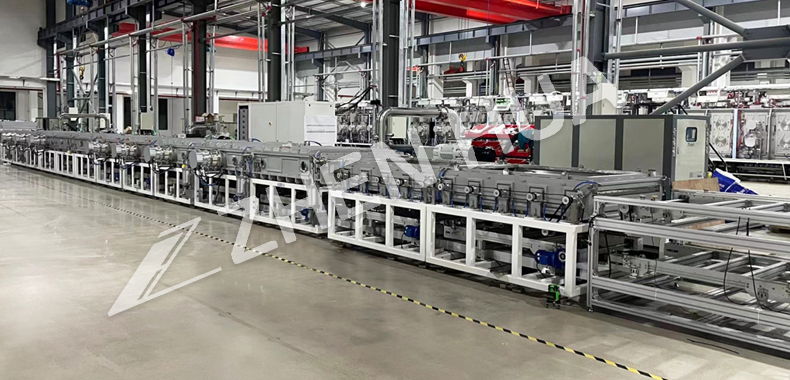

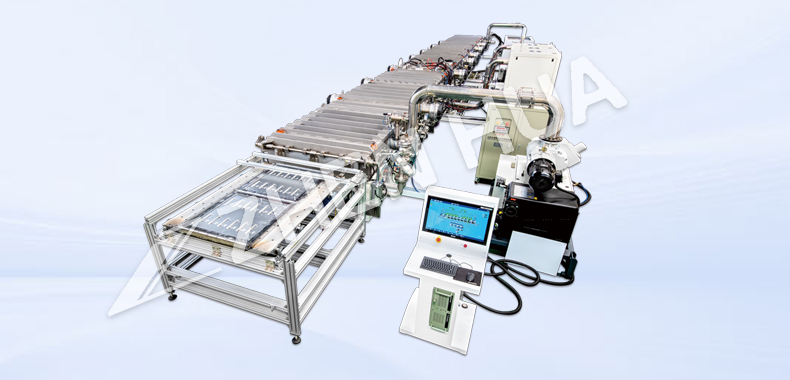

In-line vacuum coating machine: revolutionizing the coating industry

The coating industry has made significant progress thanks to in-line vacuum coating machines. This cutting-edge technology is revolutionizing the way coatings are applied, paving the way for improved efficiency and quality. In this blog post, we will explore the capabilities of this innovative ma...Read more -

Stainless steel vacuum coating machine: the future of advanced surface coating technology

In today’s rapidly evolving industrial environment, where precision and durability are critical, the demand for advanced surface coating technologies is growing. Industries such as automotive, aerospace and electronics are constantly seeking innovative ways to improve the performance, aesth...Read more -

Mirror coating machine: enhance reflective gloss

In today’s fast-paced world, technological advancements are reshaping various industries, including manufacturing. Mirror coating machines are one of the innovations that have attracted much attention. This cutting-edge device plays a vital role in improving the brightness and durability of...Read more -

Metal plating ceramic vacuum coating machine: revolutionizing surface coating

In today’s rapidly evolving world, innovative technologies are reshaping industries and pushing boundaries. One of the breakthrough technologies is the metal plating ceramic vacuum coating machine. This cutting-edge equipment is revolutionizing the surface coating industry, delivering unpar...Read more -

Plasma Direct Polymerization Film Application Areas

(1) Conductive film using tetramethyltin and other monomers for the monomer plasma polymerization into a conductive polymer containing metal to get nearly conductor polymer film. Plasma polymerization of conductive film can be used for anti-static, widely used in electronics, military, aerospace...Read more -

Optical PVD coating: revolutionizing the world of optics

In today’s ever-evolving technology landscape, optical coatings play a vital role in enhancing the performance and functionality of various optical devices. Among the many breakthroughs in this field, optical PVD coating technology is the most eye-catching process. As one of the fastest gro...Read more -

PVD Coating on Aluminum: Enhanced Durability and Aesthetics

In the field of metal surface treatment, PVD coating on aluminum has become a breakthrough technology, offering incredible advantages in terms of durability, aesthetics and cost-effectiveness. PVD (Physical Vapor Deposition) coating involves depositing a thin film of material onto the aluminum su...Read more