Welcome to Guangdong Zhenhua Technology Co.,Ltd.

Industry News

-

Nano Vacuum Coating Machines

Nano vacuum coating technology is making waves in the industry, and for good reason. It offers a range of benefits, from improved product durability and resistance to environmental degradation to enhanced physical and chemical properties. As the demand for high-quality coating continues to grow, ...Read more -

Hardware Vacuum Coating Machine

One of the most important developments in hardware vacuum coating machine technology is the introduction of advanced automation capabilities. The new machines are equipped with state-of-the-art robotic arms and computer control systems to enable precise and efficient coating processes. This autom...Read more -

Gold Color Vacuum Coating Machine

The gold vacuum coating machine uses advanced technology to deposit a thin layer of gold coating on various surfaces such as metals, ceramics, plastics, etc. The process is achieved through the use of physical vapor deposition (PVD), a technology that creates high-quality, durable finishes with e...Read more -

Car Mirror Magnetron Sputtering Line

The car mirror magnetron sputtering line utilizes advanced magnetron sputtering technology to apply a thin, uniform coating to car mirrors. This process involves the use of high-energy particles to deposit a thin film onto the surface of the mirror, resulting in a durable and high-quality finish....Read more -

Optical Ebeam Vacuum Coating System for AR AF Coating

The optical ebeam vacuum coating system for AR AF coating is a game-changer for manufacturers and consumers alike. By utilizing the power of electron beam evaporation in a vacuum environment, this cutting-edge system can precisely and uniformly apply AR and AF coatings to a variety of optical sur...Read more -

Magnetic Filtering Hard Coating Equipment

Magnetic filtration hard coating equipment is a cutting-edge technology that plays a key role in various industries including manufacturing, automotive, aerospace and more. The equipment is designed to effectively remove impurities and contaminants from coatings, ensuring a high-quality end produ...Read more -

Vacuum Coating Machine for Protective

Vacuum coaters are gaining attention for their ability to apply protective coatings to a variety of materials, including metals, plastics, glass and ceramics. This versatility makes it a valuable asset in industries such as automotive, aerospace, electronics and medical device manufacturing. As t...Read more -

Reflective Glass Coating Production Line

Demand for reflective glass coating lines has been growing steadily as companies seek to improve energy efficiency and reduce glare in buildings. This has led to a surge in research and development efforts to improve production processes and create more effective and durable coatings. One of the ...Read more -

Jewelry Accessories Pvd Coating Machines

PVD coating machines are becoming increasingly popular in the jewelry industry due to their ability to apply a variety of colors and finishes to jewelry accessories. This technology creates a vibrant and long-lasting coating that retains its luster over time. As the demand for unique and high-qua...Read more -

Introducing The Latest Fully Automatic Ion Sputtering Coating Machine

The fully automatic ion sputtering coating machine utilizes the latest advances in ion sputtering technology to provide a seamless and efficient coating process. With its fully automatic capabilities, the machine delivers unparalleled precision and consistency, ensuring the highest quality coatin...Read more -

Metal Anti Fingerprint Vacuum Coaters

The use of metal anti-fingerprint vacuum coating machines represents a major advancement in surface protection technology. By combining vacuum technology and specialized coatings, these machines create a thin, wear-resistant layer on metal surfaces that protects against fingerprints and other imp...Read more -

Practical Vacuum Coating Machine

In the fields of advanced manufacturing and industrial production, the demand for practical vacuum coating machines is increasing. These cutting-edge machines are revolutionizing the way a variety of materials are coated, delivering enhanced durability, performance and aesthetics. In this blog po...Read more -

Target Material Selection Principle and Classification

With the increasing development of sputtering coating technology, especially magnetron sputtering coating technology, at present, for any material can be prepared by ion bombardment target film, because the target is sputtered in the process of coating it to some kind of substrate, the quality of...Read more -

RF Sputtering Coating Main Features

A. High sputtering rate. For example, when sputtering SiO2, the deposition rate can be up to 200nm/min, usually up to 10~100nm/min. And the rate of film formation is directly proportional to the high frequency power. B.The adhesion between the film and the substrate is greater than the vacuum vap...Read more -

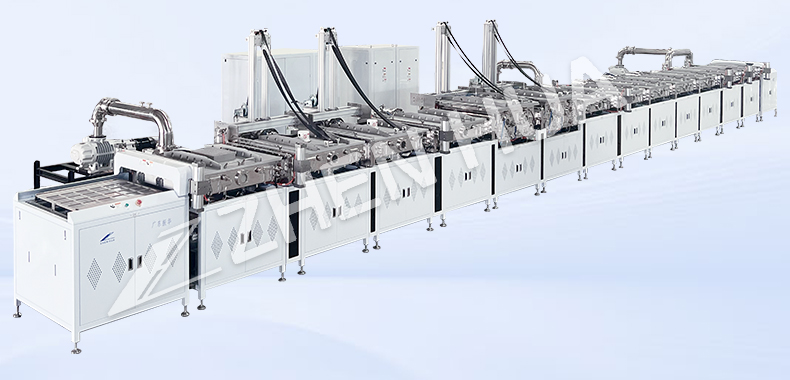

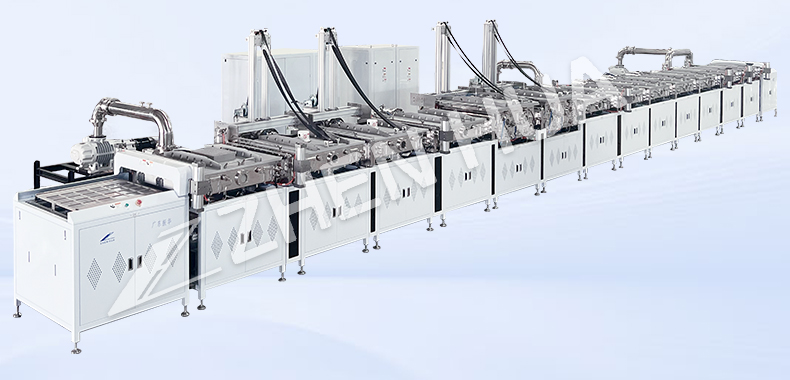

Car Lamp Film Production Coating Lines

Car lamp film production lines are an essential part of the automotive manufacturing industry. These production lines are responsible for the coating and production of car lamp films, which play a crucial role in enhancing the aesthetics and functionality of car lamps. As the demand for high-qual...Read more