One of Hottest for Aluminum Coating Of Automobile Interior Parts - Anti fingerprint coating equipment – Zhenhua

PRODUCT DESCRIPTION

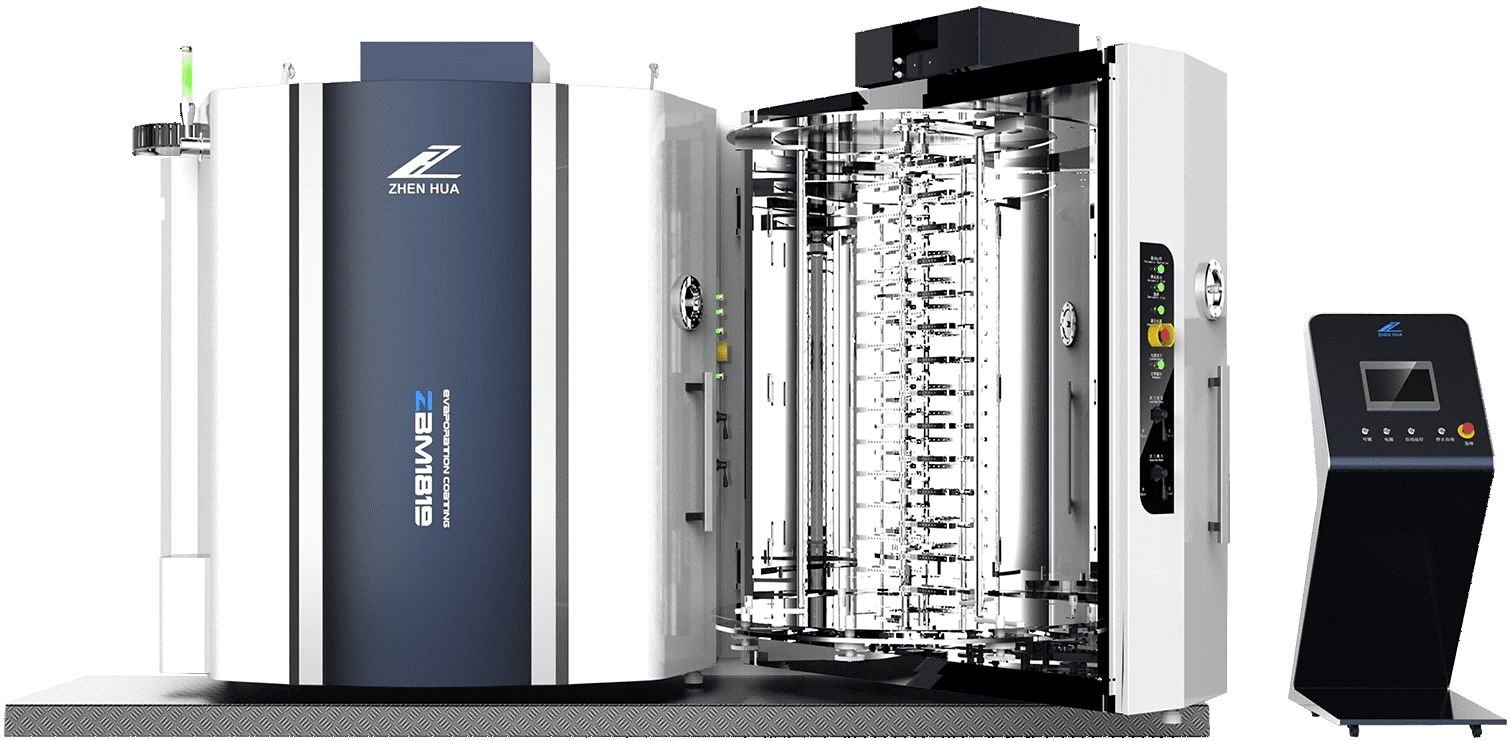

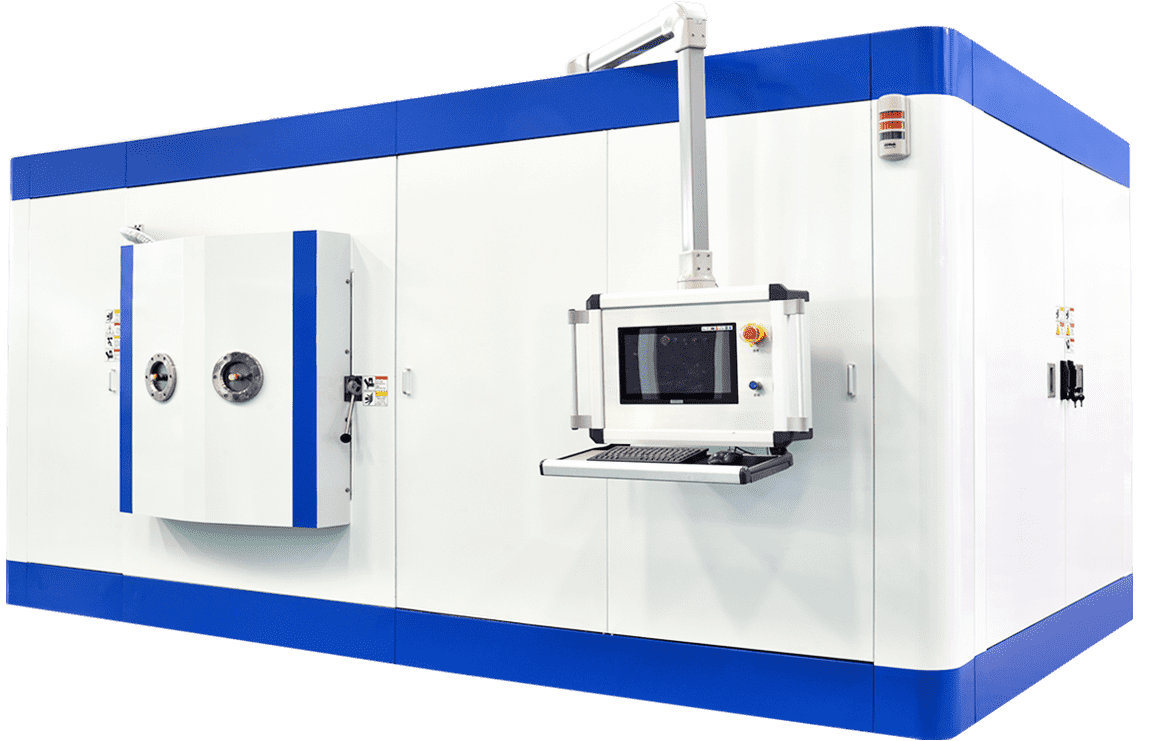

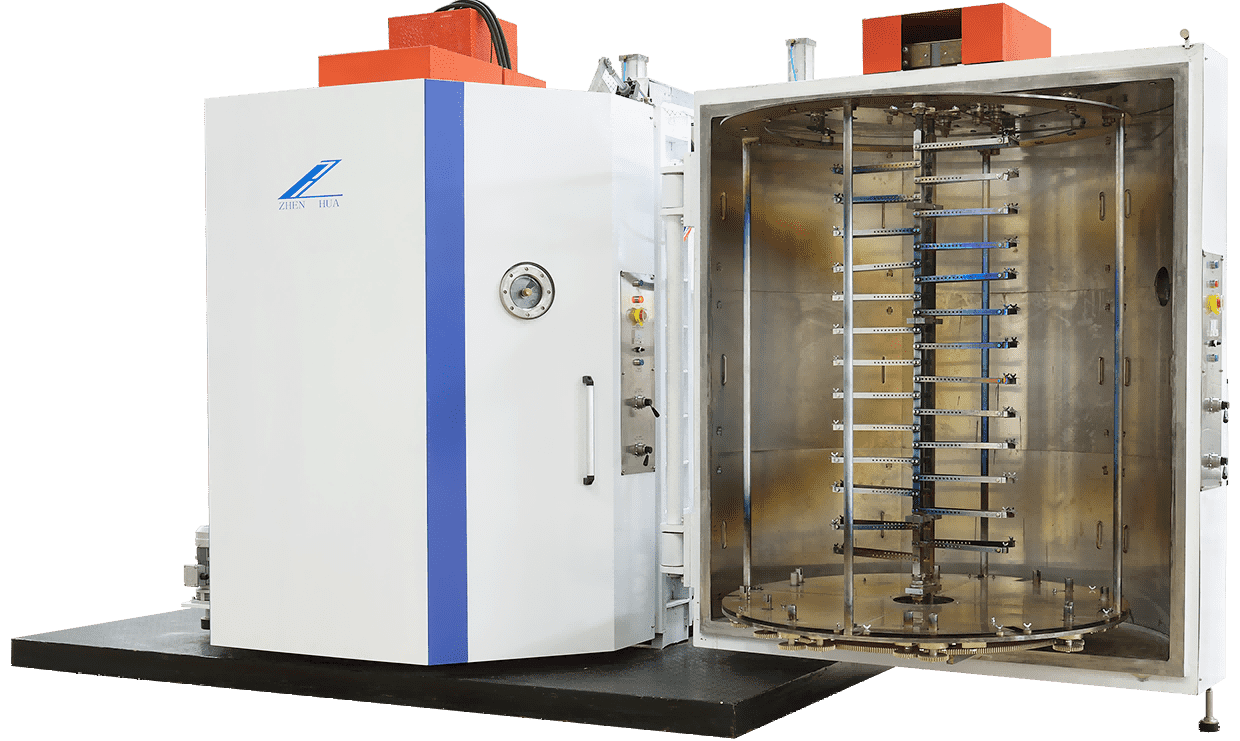

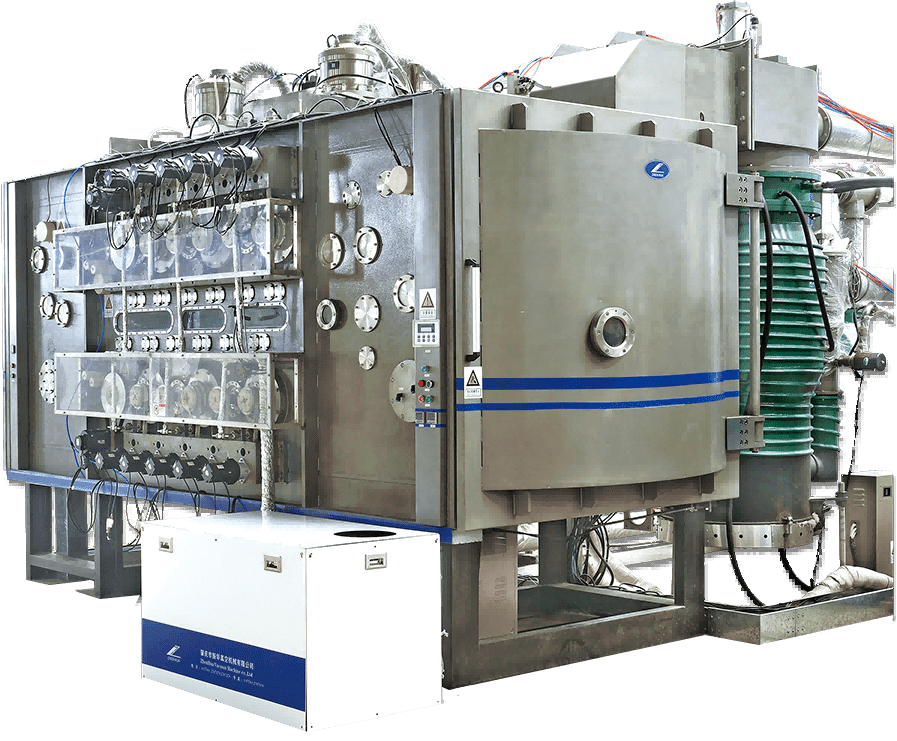

The anti fingerprint coating equipment adopts the magnetic control coating AF anti fingerprint technology, and the anti fingerprint water drop angle can reach more than 115 °. The film has good hydrophobicity, high stability, and excellent anti pollution, waterproof and wear-resistant effects. The AF anti fingerprint coating plated by the equipment has been widely used in metal parts for a long time, especially in bathroom metal parts, which has shown superior alkali resistance and friction resistance, and has been widely recognized by customers.

The equipment can deposit AF anti fingerprint and compound film, which can be applied to metal, glass, ceramic, plastic electroplated parts and other products. It has been widely used in bathroom hardware / ceramic parts, mobile phone glass cover / middle frame / keys, digital products, cameras, touch screens, clocks, jewelry, sunglasses / swimming goggles and other products.

Optional models

| AF1250 | AF1616 |

| φ1250*H1100(mm) | φ1600*H1600(mm) |

PRODUCT FEATURE

INDUSTRY APPLICATION

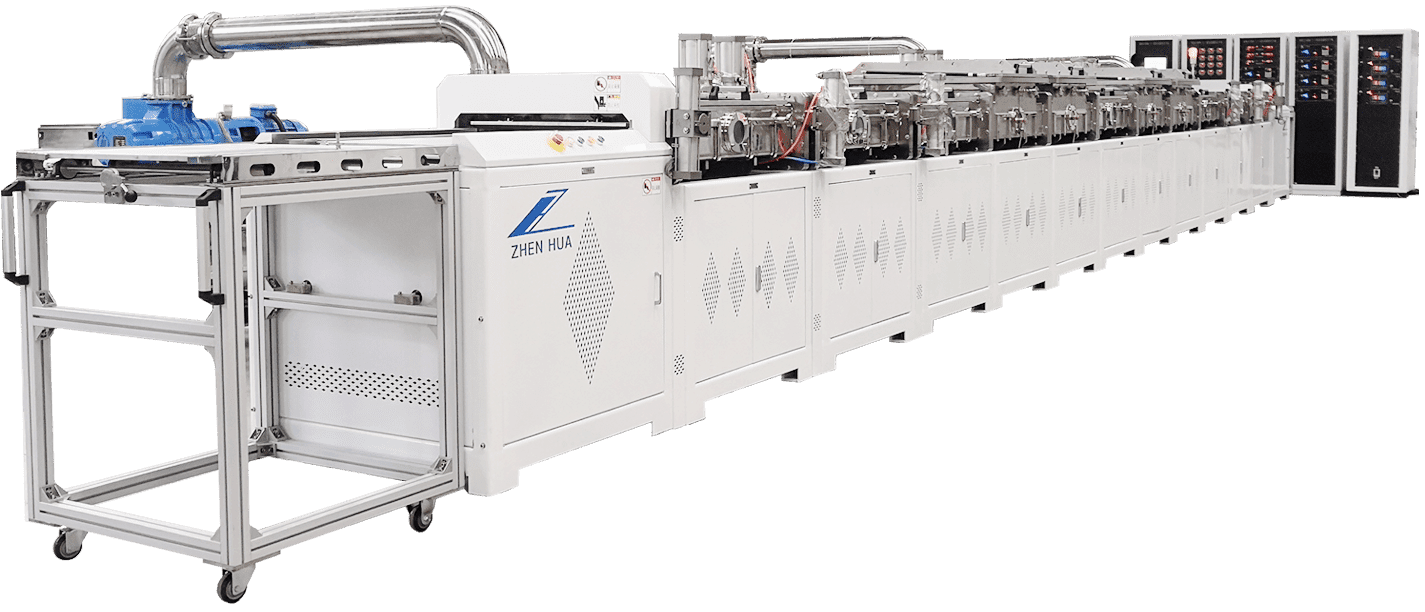

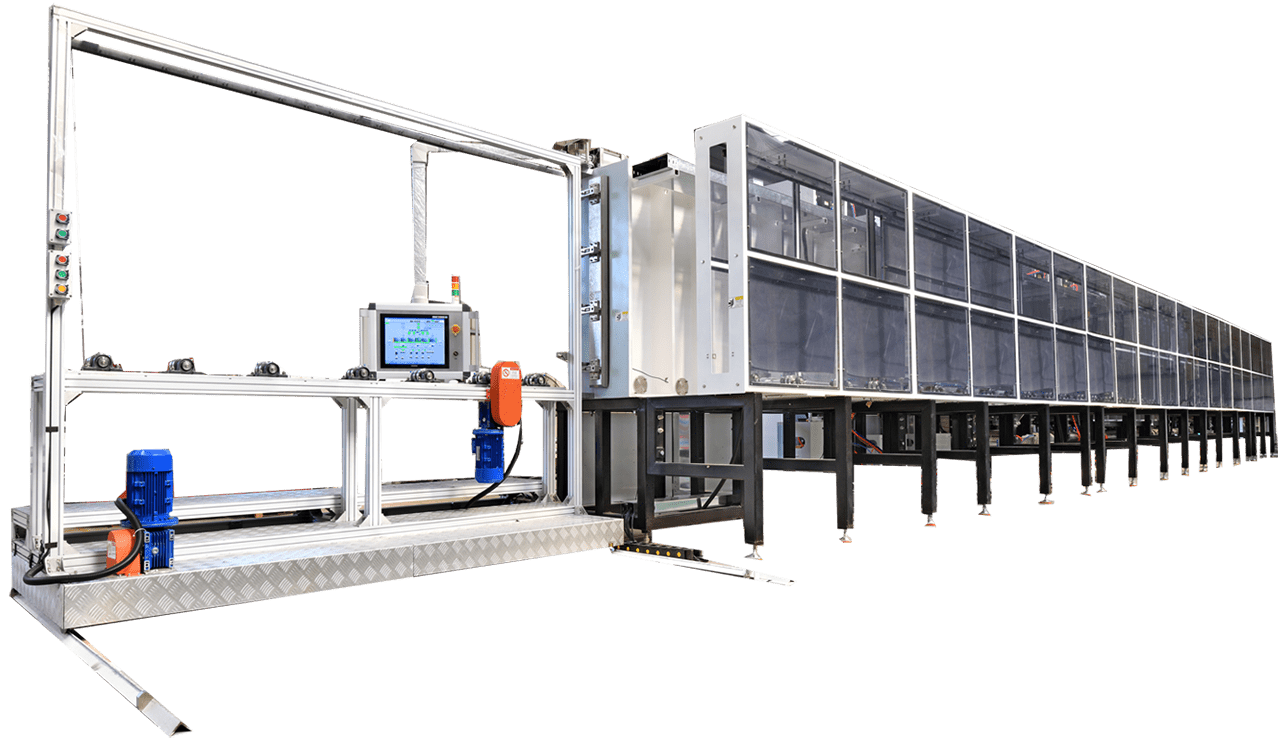

RELATIVE DEVICES

Click ViewHigh Performance Vacuum Coating Metalizing Equi...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

Wholesale Price China Bipolar Plate Pt Coating ...

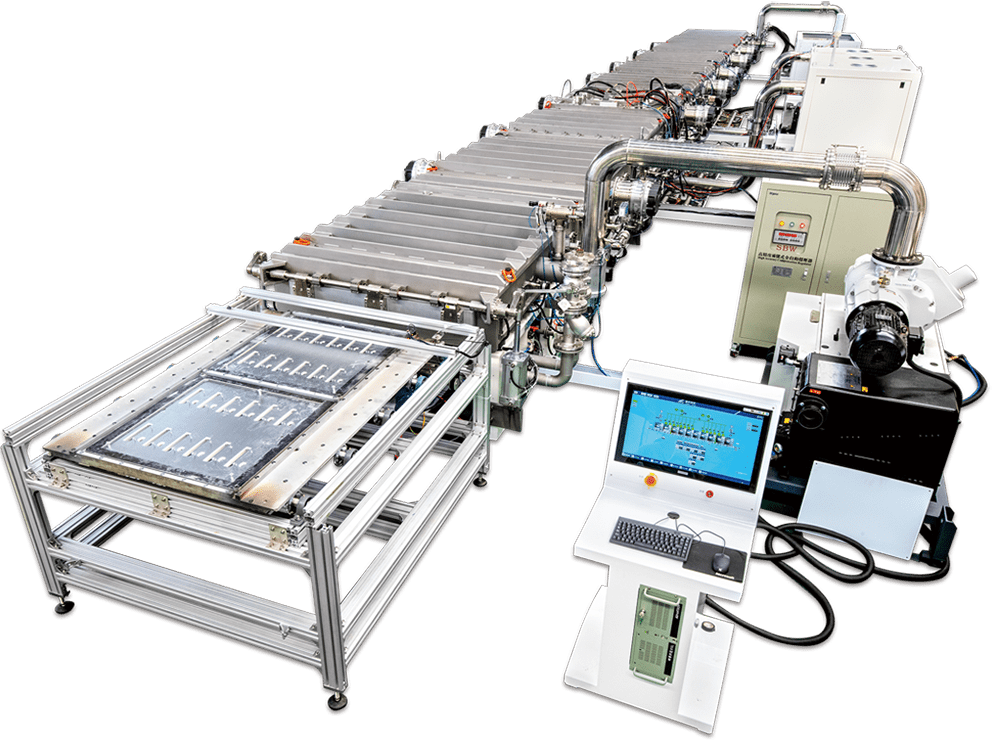

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory Cheap Pvd Machine Price - Large metal ...

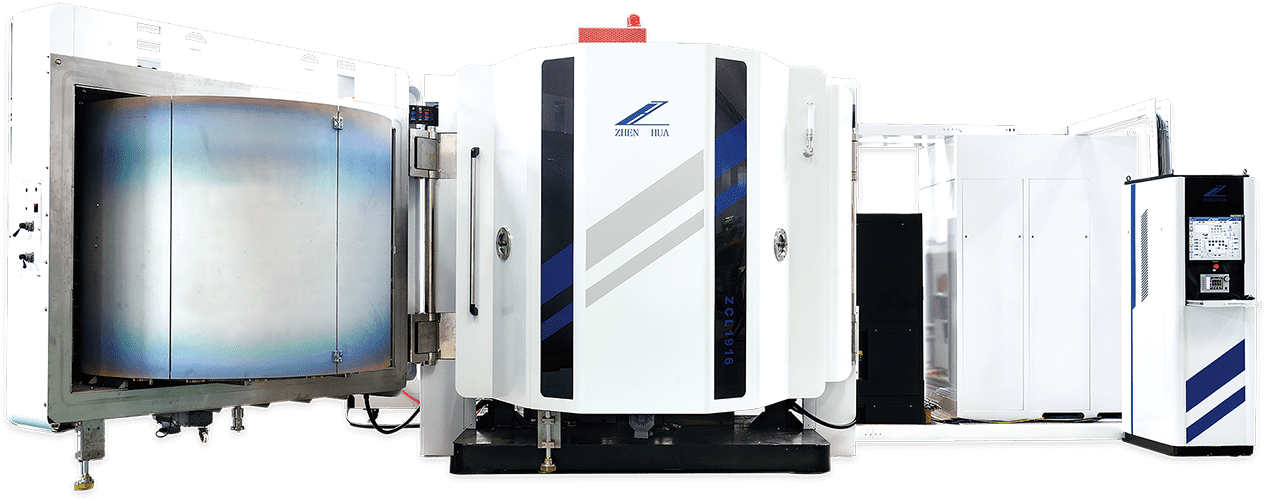

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

China Supplier Vacuum Sputtering Equipment - V...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Manufacturer for DPC Ceramic Substrate Coating ...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Manufactur standard Jewelry Wear-Resistant Coat...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

2022 China New Design Optical Vacuum Coating Eq...

The equipment integrates magnetron sputtering and ion coating technology, and provides a solution for improving color consistency, deposition rate and stability of compound composition. According t...

New Fashion Design for Bipolar Plate Anti-Corro...

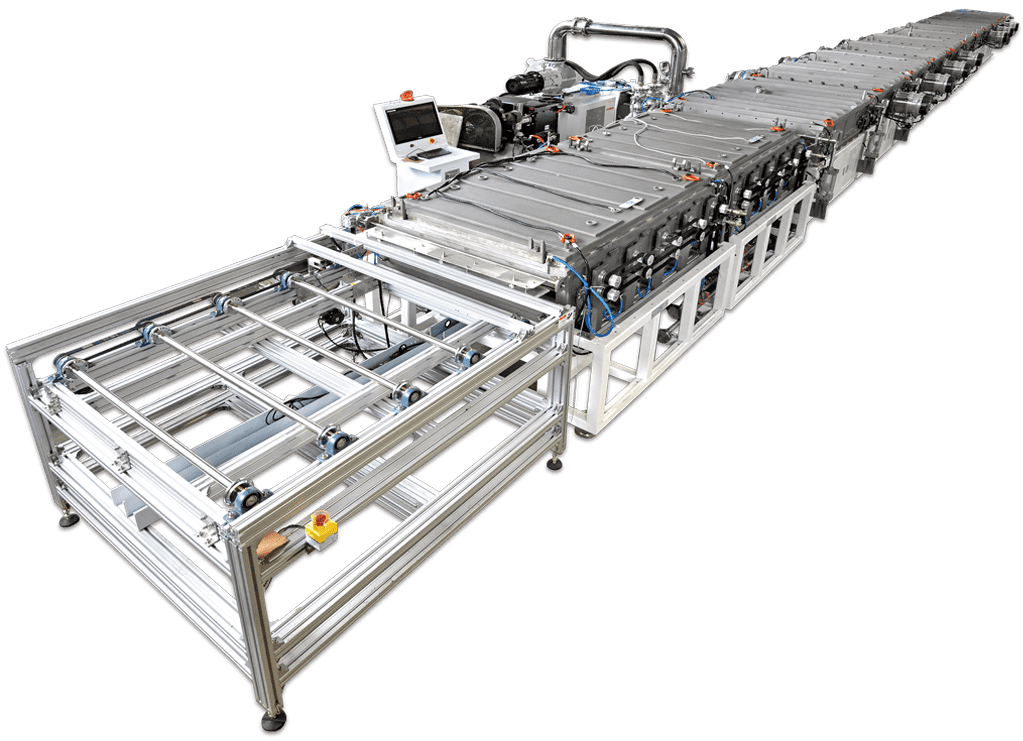

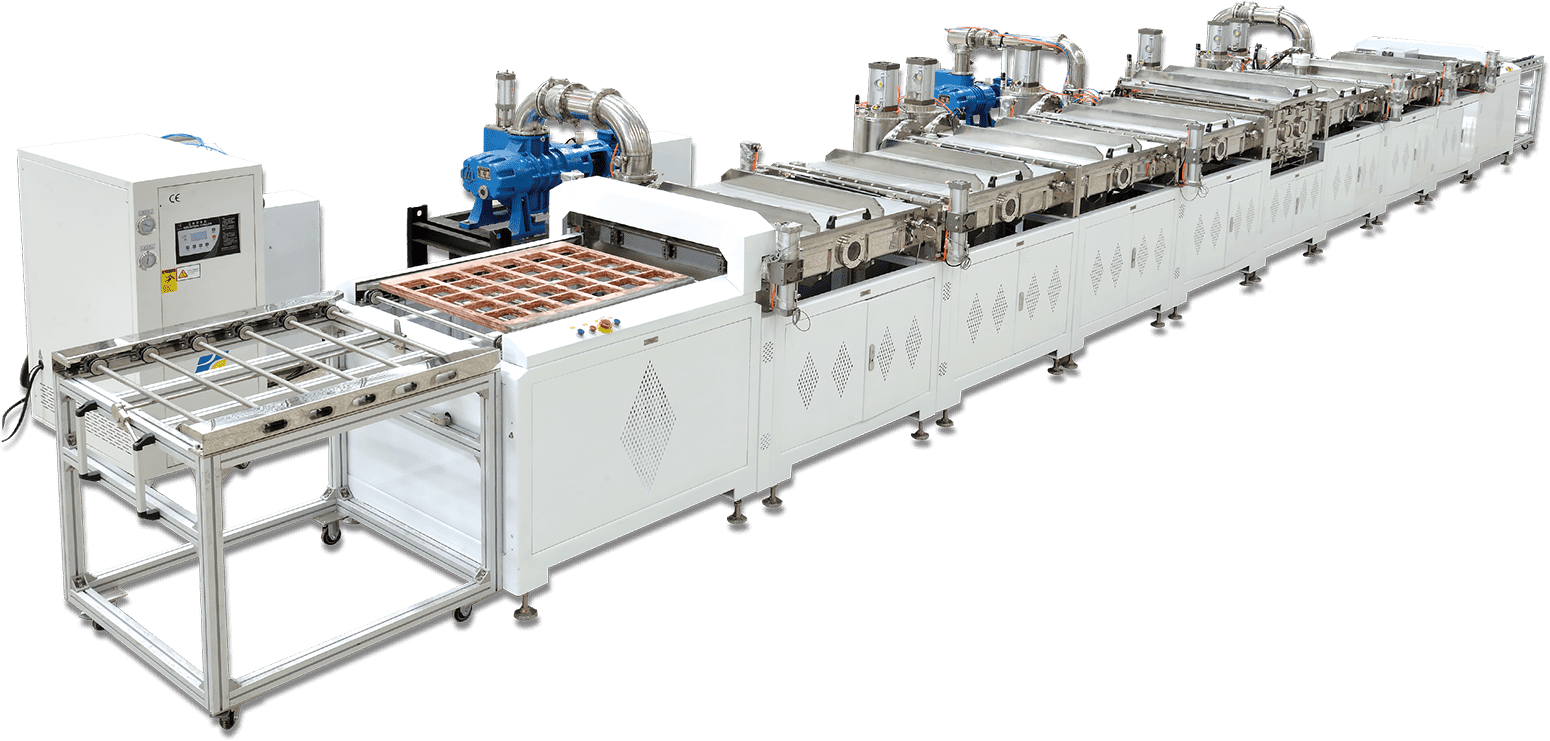

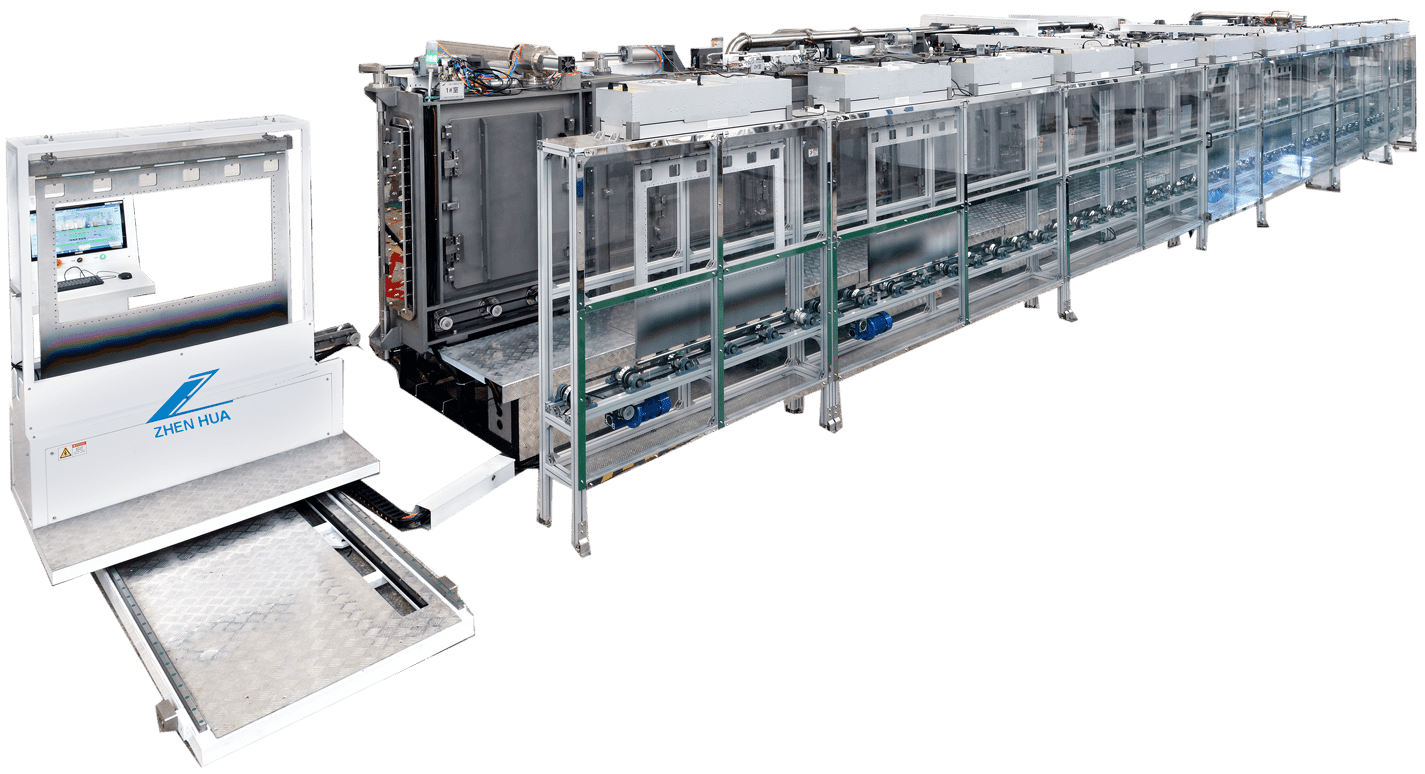

ITO / ISI horizontal continuous coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion and upgrad...

China Supplier Coating Machine Of Mobile Phone ...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

Factory Promotional Pvd Metal Coating Machine -...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Top Quality Door Handle Pvd Coating Machine - ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

factory Outlets for Metal Pvd Coating Equipment...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Europe style for Phone Back Cover Coating - Ho...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

Factory Price For Bipolar Carbon Coating Machin...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

8 Year Exporter Camera Coating Machine - Exper...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Factory Promotional Car Light Evaporation Coati...

Sapphire film hard coating equipment is a professional equipment for depositing sapphire film. The equipment integrates three coating systems of medium frequency reactive magnetron sputtering + CVD...

Hot sale Factory Backless Lamp Coating Equipmen...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Good Wholesale Vendors Vehicle Logo Coating - ...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Cheap PriceList for Continuous Coating Line - ...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

2022 wholesale price Vacuum Coating Machine Pri...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

Big Discount Sputtering Equipment Manufacturers...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

New Arrival China Vacuum Film Coating Equipment...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Good Quality Hard Film Vacuum Coating Equipment...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Hot sale Factory Sputtering Machine Manufacture...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

Excellent quality Door Hardware Pvd Coating Equ...

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Online Exporter Chrome Pvd Vacuum Coating Equip...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Super Purchasing for Cutting Tools Vacuum Coati...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

Short Lead Time for NCVM Coating (3C Products) ...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Original Factory Vacuum Coating Machine Manufac...

The anti fingerprint coating equipment adopts the magnetic control coating AF anti fingerprint technology, and the anti fingerprint water drop angle can reach more than 115 °. The film has good hyd...

Cheap PriceList for AF Coating For Jewelry - E...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

China Gold Supplier for Pvd Coating Machine For...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Good User Reputation for Lithium Battery Compou...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Wholesale Price Optical Film Coating Machine -...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory Price For Chrome Plating For Automotive...

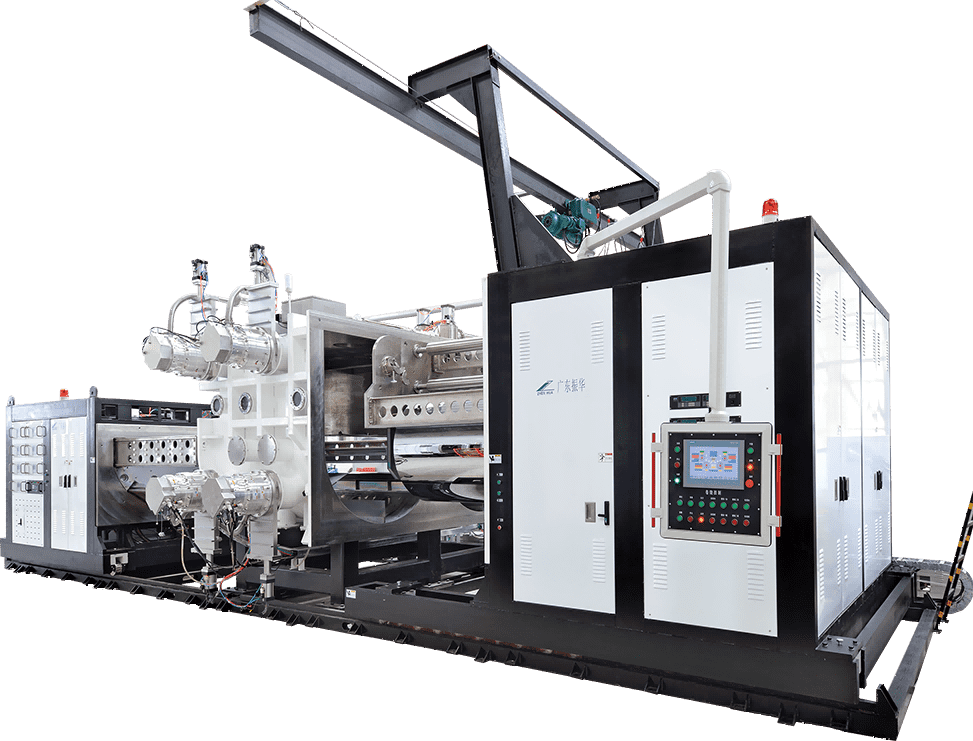

Magnetron winding coating equipment is to use magnetron sputtering method to change the coating material into gaseous or ionic state in the vacuum environment, and then deposit it on the work-piece...

High Quality for Continuous Steel Coil Color Co...

The equipment adopts cathode arc ion coating technology and is equipped with advanced IET etching system. After treatment, the product can directly deposit hard coating without transition layer. At...

Lowest Price for DPC Ceramic Substrate Coating ...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Original Factory Metal Pvd Vacuum Coating Machi...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Wholesale Price Decorative Pvd Coatings Equipme...

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Low price for Sputtering Machine Manufacturers ...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

2022 Good Quality DPC Ceramic Substrate - GX27...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Wholesale Price Eyeglass Lens Optical Vacuum Co...

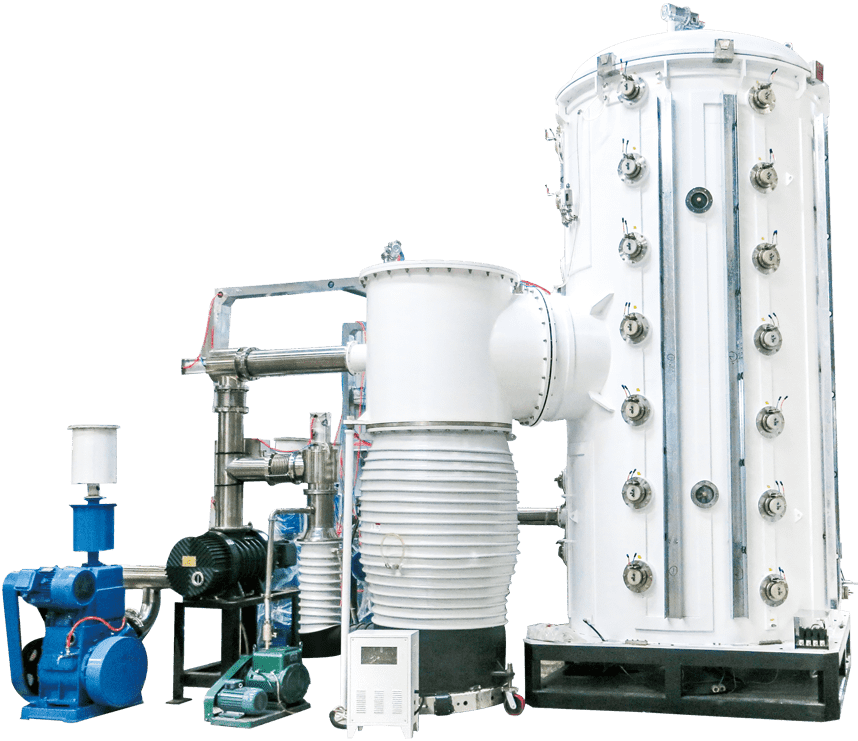

In the vacuum chamber, the coating material is vaporized and deposited on the substrate by using the resistance heating method, so that the surface of the substrate can obtain metal texture and ach...

China Factory for One Year Warranty Magnetron S...

Magnetron winding coating equipment is to use magnetron sputtering method to change the coating material into gaseous or ionic state in the vacuum environment, and then deposit it on the work-piece...

Top Quality Sputtering Deposition Equipment - ...

This series of equipment converts the coating materials with low melting point and easy to evaporate into nano particles by heating in the medium frequency induction furnace or evaporation molybden...

professional factory for Auto Spare Parts Sputt...

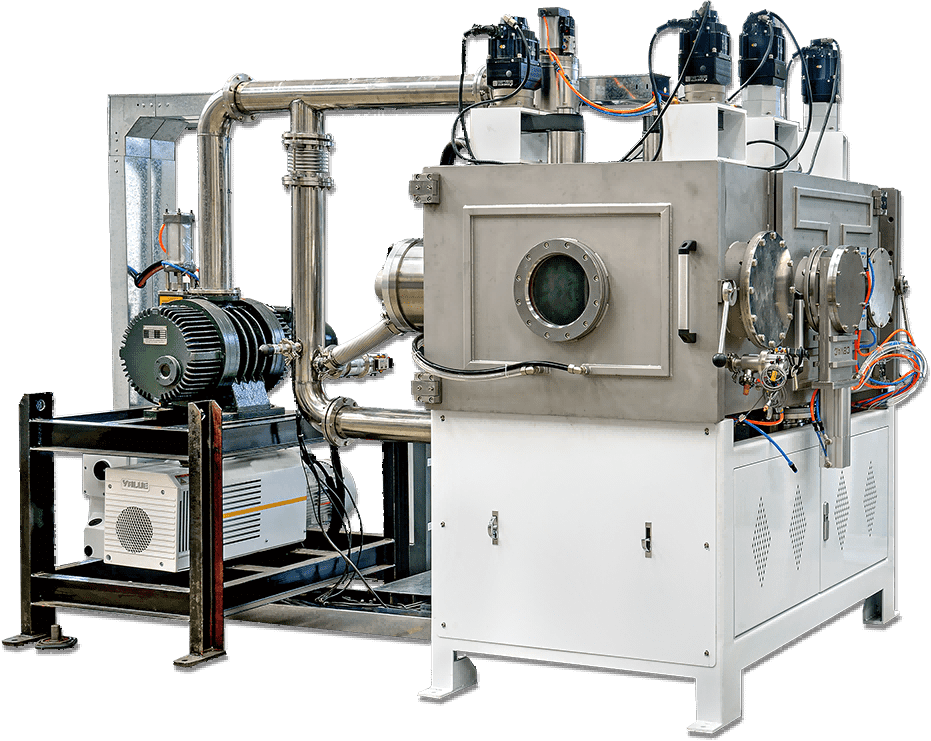

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Factory making Pvd Coating Machine Suppplier -...

With the rapid growth of the market demand for improving the wear resistance, lubrication, corrosion resistance and other properties of hard coatings, cathodic arc magnetic filtration ion coating e...

Factory Cheap Lamp Coating Equipment - Horizon...

The coating line adopts modular structure, which can increase the chamber according to the process and efficiency requirements, and can be coated on both sides, which is flexible and convenient. Eq...

Cheapest Factory Cvd Coating Machine Companies ...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

Hot-selling Ar Film Vacuum Coating Machine - S...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

Wholesale Price China Coating Machine For Autom...

The equipment integrates magnetron sputtering and ion coating technology. According to different product requirements, heating system, bias system, ionization system and other devices can be select...

Personlized Products Vacuum Coating Equipment F...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Wholesale Lithium Battery Composite Film Copper...

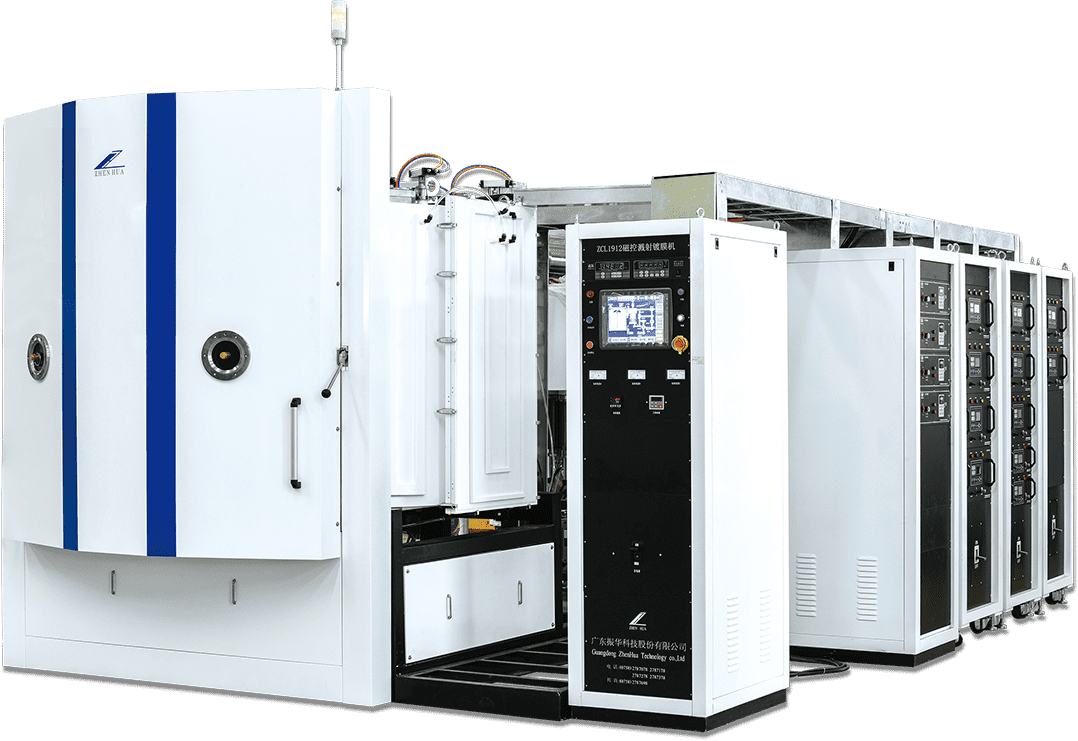

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

High reputation China Vacuum Coating Machine Su...

The equipment adopts the cathode arc evaporation ion coating technology, which has the characteristics of fast deposition rate, high energy and high metal ionization rate. The cathode arc can be co...

Excellent quality Pvd Coating Equipment Germany...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Excellent quality Decorative Vacuum Coating Mac...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Excellent quality Decorative Vacuum Coating Mac...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

High definition Small Pvd Coating Equipment - ...

Optional models Vertical multifunctional coating production line Vertical decorative film coating production line

China Gold Supplier for Pvd Coating Machine For...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Wholesale Price Perovskite Battery - Large sca...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Discountable price Titanium Nitride Coating Pvd...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

China Manufacturer for Multi Arc Ion Coating Ma...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Cheap PriceList for Vacuum Coating Machines Chi...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

Popular Design for Drill Tools Pvd Coating Equi...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Newly Arrival Metallized Evaporation Vacuum Coa...

In the vacuum state, place the workpiece on the cathode of low-pressure glow discharge and inject appropriate gas. At a certain temperature, a coating is obtained on the surface of the workpiece by...

factory Outlets for Metal Pvd Coating Equipment...

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

Fast delivery Anti Oxidation Coating Machine Fo...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Best-Selling Post Oxidation Coating - Hardness...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

One of Hottest for Magnetron Sputtering Equipme...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

Hot Selling for Door Handle Pvd Coating Equipme...

This series of equipment converts the coating materials with low melting point and easy to evaporate into nano particles by heating in the medium frequency induction furnace or evaporation molybden...

OEM/ODM China TaC Hard Coating - Vertical doub...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

2022 High quality Hard Coating Machine - Preci...

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

Chinese wholesale Pvd Coating Machine Cost - V...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Wholesale Dealers of Sputtering Vacuum Coating ...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

Low MOQ for Sputtering Machine Coating - Oxid...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

China Cheap price Reflective Cup Base Free Coat...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Newly Arrival Metallized Evaporation Vacuum Coa...

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

New Arrival China Vacuum Film Coating Equipment...

The coating line adopts vertical modular structure design and is equipped with multiple access doors, which is convenient for independent installation and maintenance of the cavity, assembly and fu...

Factory wholesale Pvd Coating System - Oxidat...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

Factory supplied Automotive Car Light Vacuum Co...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

Chinese wholesale AlN/Al₂O₃ Coating - Horizont...

With the national attention to industrial environmental protection, the water electroplating process is gradually abandoned. At the same time, with the rapid growth of demand in the automotive indu...

Reasonable price Cu Coating - GX2700 Electron ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Good Quality Metal Gold Evaporation Coating Mac...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory Cheap TiN Coating Machine - Double doo...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

2022 New Style Sputtering Equipment Coating - ...

In the vacuum state, place the workpiece on the cathode of low-pressure glow discharge and inject appropriate gas. At a certain temperature, a coating is obtained on the surface of the workpiece by...

Professional Design Titanium Nitride Coating Pv...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Factory Cheap TiN Coating Machine - Hardness f...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...