Nheyo yevacuum evaporation coating

1, Zvishandiso uye maitiro emuviri wevacuum evaporation coating

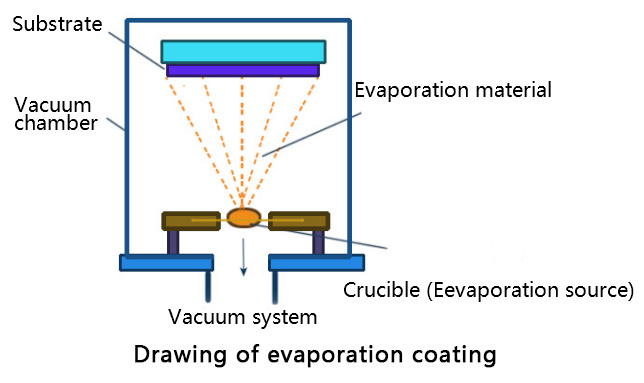

Iyo vacuum evaporation yekubatisa midziyo inonyanya kuumbwa neyevacuum chamber uye evacuation system. Mukati mevacuum room, mune evaporation sosi (kureva evaporation heater), substrate uye substrate furemu, substrate hita, exhaust system, nezvimwe.

Iyo yekuputira inoiswa mune evaporation sosi yevacuum chamber, uye pasi peyakanyanya vacuum mamiriro, inopiswa neiyo evaporation sosi kuti ibude. Kana avhareji yemahara yemhando yemamorekuru emhute yakakura kupfuura mutsara saizi yekamuri yekutsvaira, mushure mekunge maatomu nemamorekuru emhute yefirimu apukunyuka kubva pamusoro peiyo sosi yekubuda, haawanzo kudziviswa nekudhumhana kwemamwe mamorekuru kana maatomu, uye akananga pamusoro peiyo substrate kuti ivharwe. Pamusana pekushisa kwakadzika kwe substrate, iyo firimu vapor particles inoputika pairi uye inogadzira firimu.

Kuti uvandudze kunamatira kwemamorekuru evaporation uye substrate, iyo substrate inogona kushandiswa nekudziya kwakakodzera kana kuchenesa ion. Vacuum evaporation coating inoenda nenzira dzinotevera dzemuviri kubva pakubuda kwezvinhu, kutakurwa kuenda kunoiswa mufirimu.

(1)Kushandisa nzira dzakasiyana-siyana kushandura mamwe marudzi esimba kuita simba rinopisa, iyo firimu zvinhu zvinopisa kuti zvinyunguduke kana kuti sublimate kuita gaseous particles (atomu, mamorekuru kana maatomu masumbu) ane humwe huwandu hwesimba (0.1 kusvika 0.3 eV).

(2) Gaseous particles anosiya pamusoro pefirimu uye anotakurwa kuenda pamusoro pe substrate pane imwe spidhi yekufamba, zvakanyanya pasina kudhumhana, mumutsara wakatwasuka.

(3) Iwo magasi zvimedu zvinosvika pamusoro peiyo substrate coalesce uye nucleate, uye zvino inokura kuita yakasimba-chikamu firimu.

(4)Kuronga patsva kana kubatanidza kemikari kwemaatomu anoumba firimu.

2, Evaporation kudziyisa

(1) Resistance heat evaporation

Resistance heat evaporation ndiyo yakapfava uye inowanzo shandiswa kupisa nzira, inowanzo shandiswa pakupfekedza zvinhu zvine nzvimbo yekunyungudika pazasi 1500 ℃, yakakwira simbi inonyungudika muwaya kana shizha chimiro (W, Mo, Ti, Ta, boron nitride, nezvimwewo) inowanzo gadzirwa kuita chimiro chakakodzera chekuputira sosi, inotakurwa neinopfungaira kune yekupisa kwezvinhu, kuburikidza neiyo evaporate mepu yehuputi, kuburikidza neiyo evaporic mepu. plating zvinhu, chimiro che evaporation sosi inonyanya kusanganisa multi-strand spiral, U-shaped, sine wave, nhete ndiro, chikepe, cone basket, etc. Panguva imwecheteyo, iyo nzira inoda kuti evaporation source material ive nepamusoro pekunyungudika, low saturation vapor pressure, kugadzikana kwemakemikari zvivakwa, kwete kuva nekemikari inopindirana neyokuputira zvinhu pakukwirira kwepamusoro, kushanduka kwesimba, kushanduka kwesimba, kupisa kwakanaka, kupisa kwemhepo kunopisa. tsime rekuita kuti ridziye uye rinyungudze iyo firimu zvinhu nekudziya kwakananga, kana kuisa iyo firimu zvinhu mucrucible yakagadzirwa negraphite uye mamwe epamusoro tembiricha anodzivirira simbi oxides (seA202, B0) uye zvimwe zvinhu zvekudziya zvisina kunanga kuti zvinyunguduke.

Resistance heat evaporation coating ine zvisingakwanisi: refractory metals ine low vapor pressure, iyo yakaoma kugadzira firimu yakaonda; zvimwe zvinhu zviri nyore kugadzira alloy newaya yekudziya; hazvisi nyore kuwana yunifomu yekuumbwa kwefirimu yealloy. Nekuda kwechimiro chakareruka, mutengo wakaderera uye nyore kushanda kwekupokana kudziyisa evaporation nzira, iri yakajairika kushandiswa kweevaporation nzira.

(2) Electron danda kudziyisa evaporation

Electron beam evaporation inzira yekufefetedza iyo yekuputira nekuibhomba nehigh-energy density elekitironi danda nekuiisa mumvura-yakatonhodzwa copper crucible. Iyo evaporation sosi ine maerekitironi emission source, electron acceleration power source, crucible (kazhinji copper crucible) , magnetic field coil, uye inotonhorera mvura set, etc. Muchigadziro ichi, zvinhu zvinopisa zvinoiswa mumvura-yakatonhorera crucible, uye electron danda remagetsi rinoramba richibhomba pasi pechinhu chiduku zvikuru chechinhu chakasara chemhepo inotonhorera. iyo crucible, iyo inogona kutorwa sechikamu chakabhombwa che crucible. Nekudaro, iyo nzira yekudziya erekitironi danda rekubuda mumhepo inogona kudzivirira kusvibiswa pakati pechinhu chekuputira uye evaporation sosi zvinhu.

Mamiriro eelectron beam evaporation source anogona kupatsanurwa mumhando nhatu: pfuti dzakatwasuka (Boules pfuti), pfuti dzemhete (dzinodzorwa nemagetsi) uye e-pfuti (yakadzoserwa magineti). Imwe kana kupfuura crucibles inogona kuiswa munzvimbo inoputika, iyo inogona kubuda uye kuisa zvinhu zvakawanda zvakasiyana panguva imwe chete kana zvakasiyana.

Electron beam evaporation masosi ane zvinotevera zvakanakira.

①Iyo yakakwira danda density ye electron beam bombardment evaporation sosi inogona kuwana yakawedzera simba density pane inopokana kudziyisa sosi, iyo inogona kufambisa yakakwira yekunyungudika zvinhu, senge W, Mo, Al2O3, nezvimwe.

②Iyo yekuputira inoiswa mumvura-yakatonhorera yemhangura crucible, iyo inogona kudzivirira kubuda kweiyo evaporation sosi zvinhu, uye kuita pakati pavo.

③Kupisa kunogona kuwedzerwa zvakananga pamusoro pechinhu chekuputira, izvo zvinoita kuti kupisa kwemafuta kukwire uye kurasikirwa kwekupisa conduction uye kupisa mwaranzi kudzikira.

Kuipa kweyerekitironi danda kudziyisa evaporation nzira ndeyokuti maerekitironi ekutanga kubva papfuti yerekitironi uye maerekitironi echipiri kubva pamusoro pechinhu chekuputira anozoisa maatomu ari kubuda uye mamorekuru egasi asara, izvo zvinozokanganisa kunaka kwefirimu dzimwe nguva.

(3) High frequency induction heat evaporation

Yakakwira-frequency induction heat evaporation ndeyekuisa iyo crucible ine coating zvinhu pakati peyakakwira-frequency spiral coil, kuitira kuti iyo yekubikira ibudise yakasimba eddy ikozvino uye hysteresis mhedzisiro pasi pekupinzwa kweyepamusoro-frequency electromagnetic field, izvo zvinoita kuti firimu ridziye kusvika ranyura nekubuda. Iyo evaporation sosi kazhinji ine mvura-yakatonhodzwa high-frequency coil uye graphite kana ceramic (magnesium oxide, aluminium oxide, boron oxide, nezvimwewo) crucible. Iyo yakakwira frequency magetsi inoshandisa frequency zviuru gumi kusvika kumazana akati wandei ezviuru Hz, simba rekuisa rakati wandei kusvika kumazana akati wandei kilowatts, iyo idiki vhoriyamu ye membrane zvinhu, iyo yakakwirira induction frequency. Induction coil frequency inowanzo gadzirwa nemvura-yakatonhorera mhangura chubhu.

Izvo zvakashata zve-high-frequency induction heat evaporation nzira ndeyokuti haisi nyore kugadzirisa simba rekuisa, ine zvinotevera zvinobatsira.

①Kukwira kwemvura zhinji

②Tembiricha yeiyo evaporation sosi inofanana uye yakagadzikana, saka hazvisi nyore kuburitsa chiitiko chekuputira madonhwe anoputika, uye zvakare inogona kudzivirira chiitiko chepinholes pafirimu rakaiswa.

③Iyo evaporation sosi inoremerwa kamwe, uye tembiricha iri nyore uye iri nyore kudzora.

Nguva yekutumira: Oct-28-2022