Nidaamka polymerization tooska ah ee Plasma

Habka polymerization Plasma waa mid fudud oo loogu talagalay qalabka polymerization ee gudaha iyo qalabka elektaroonigga dibadda, laakiin xulashada halbeegga ayaa aad uga muhimsan polymerization Plasma, sababtoo ah xuduudaha ayaa saameyn weyn ku leh qaab dhismeedka iyo waxqabadka filimada polymer-ka inta lagu jiro polymerization Plasma.

Tallaabooyinka qalliinka ee polymerization plasma tooska ah waa sida soo socota:

(1) faaruqinta

Faakuumka asalka ah ee polymerization ee xaaladaha faakuumka waa in lagu shubaa 1.3 × 10-1Pa. Dareen-celinta polymerization ee u baahan shuruudo gaar ah si loo xakameeyo oksijiinta ama waxa ku jira nitrogen, shuruudaha faakuumka asalka ah ayaa xitaa ka sarreeya.

(2) Dabool falcelinta monomer ama gaasta isku qasan ee gaaska side iyo monomer

Heerka faakuumka waa 13-130Pa. Polymerization Plasma ee u baahan shaqo, habka xakamaynta socodka ku habboon iyo heerka socodka waa in la doortaa, guud ahaan 10.100mL/min. Plasma, molecules monomer ayaa ionized oo kala qaybiya bamka qaybaha tamarta, taasoo keentay qaybo firfircoon sida ion iyo hiddo-wade firfircoon. Qaybaha firfircoon ee ay ku shaqeystaan balasma waxay mari karaan polymerization Plasma ee isdhexgalka wajiga gaaska iyo wejiga adag. monomer-ku waa isha horudhac u ah polymerization Plasma, iyo gaaska falcelinta galinta iyo monomerku waa inay lahaadaan nadiif gaar ah.

(3) Xulashada tamarta kicinta

Plasma waxaa lagu soo saari karaa iyadoo la adeegsanayo DC, soo noqnoqoshada sare, RF, ama ilaha tamarta microwave si loo bixiyo jawi balaasmaha loogu talagalay polymerization. Xulashada korantada waxaa lagu go'aamiyaa iyadoo lagu saleynayo shuruudaha qaab dhismeedka iyo waxqabadka polymer-ka.

(4) Xulashada qaabka dheecaanka

Shuruudaha polymerka, polymerization Plasma wuxuu dooran karaa laba nooc oo dareere ah: dheecaan joogto ah ama dareere garaaca wadnaha.

(5) Xulashada cabbirrada dareeraha

Marka la samaynayo polymerization Plasma, cabbirada dareeraha ayaa loo baahan yahay in laga fiirsado cabbirrada balaasmaha, guryaha polymer iyo shuruudaha qaabdhismeedka. Baaxadda awoodda la dabaqay inta lagu jiro polymerization waxaa lagu go'aamiyaa mugga qolka faakuumka, cabbirka korantada, heerka socodka monomer iyo qaab dhismeedka, heerka polymerization, iyo qaab dhismeedka polymer iyo waxqabadka. Tusaale ahaan, haddii mugga qolka falcelinta uu yahay 1L iyo RF Plasma polymerization la qaatay, awoodda sii dayntu waxay ahaan doontaa inta u dhaxaysa 10 ~ 30W. Xaaladahan oo kale, balasmaha la soo saaray ayaa isku dari kara si ay u sameeyaan filim khafiif ah oogada sare ee shaqada. Heerka kobaca ee filimka polymerization Plasma wuxuu ku kala duwan yahay sahayda korontada, nooca monomer iyo heerka socodka, iyo xaaladaha habka. Guud ahaan, heerka kobaca waa 100nm/min ~ 1um/daqiiqo.

(6) Cabbirka cabbirka ee Plasma polymerization

Halbeegyada balasmaha iyo halbeegyada habraaca lagu cabbirayo Plasma polymerization waxaa ka mid ah: korantada dareeraha, soo saarista hadda, soo noqnoqda, heerkulka Electron, cufnaanta, nooca kooxda falcelinta iyo feejignaanta, iwm.

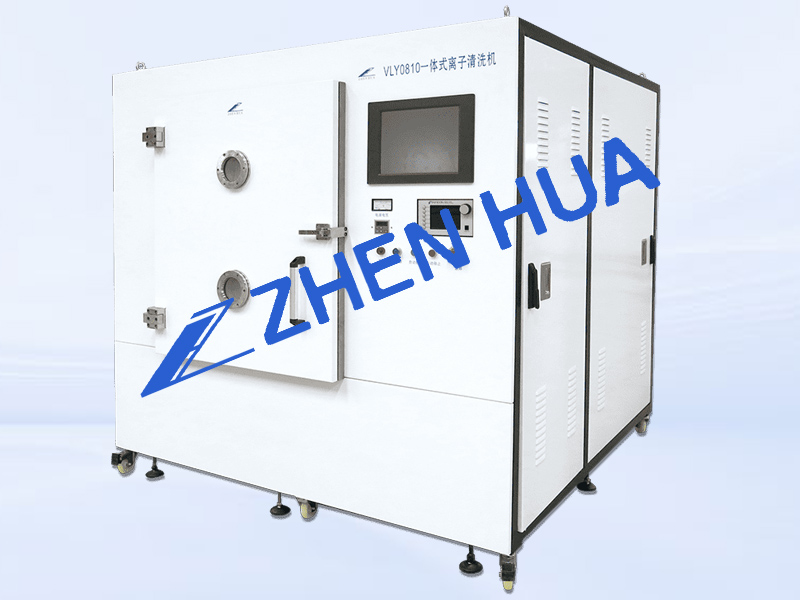

——Maqaalkan waxaa sii daayay Guangdong Zhenhua Technology, asoo saaraha mashiinada daahan indhaha.

Waqtiga boostada: May-05-2023