Special Price for Rf Sputtering Equipment - Double door evaporation coating equipment – Zhenhua

PRODUCT DESCRIPTION

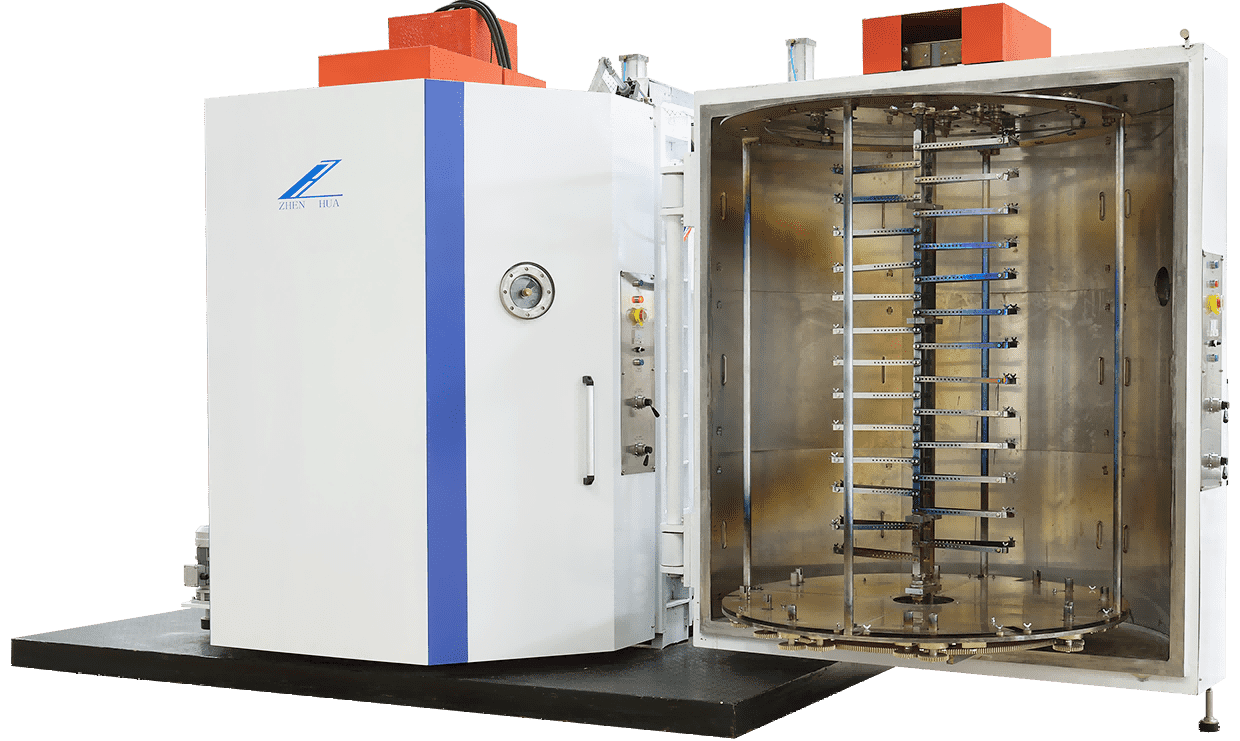

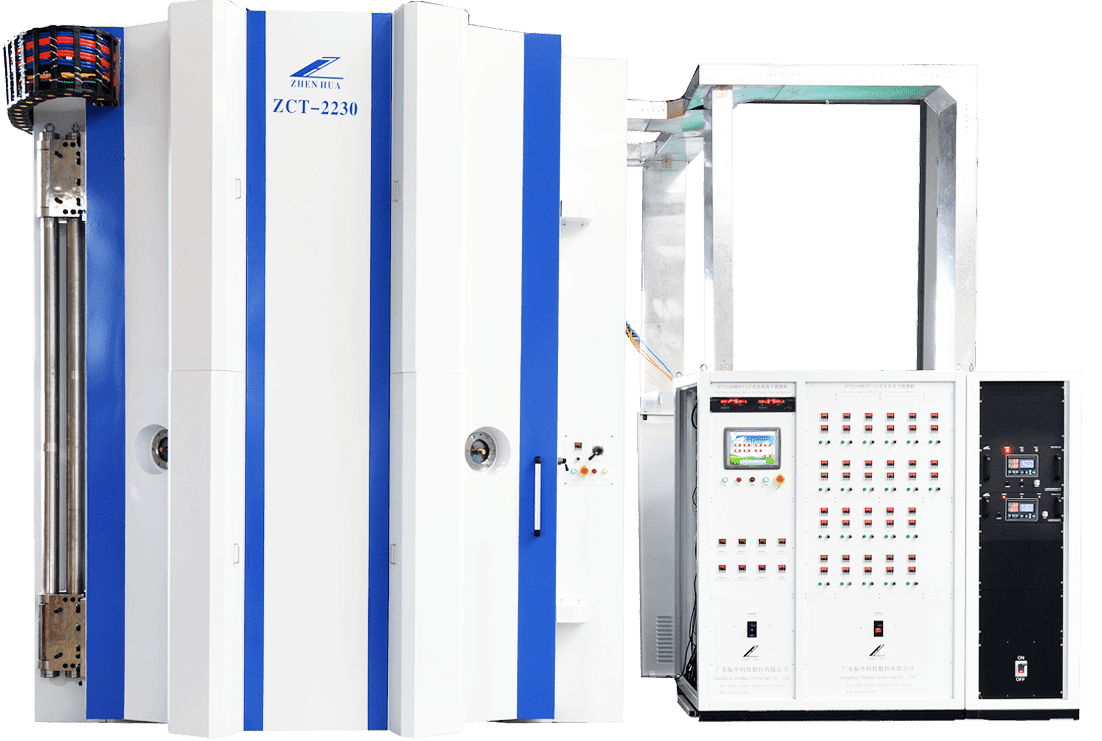

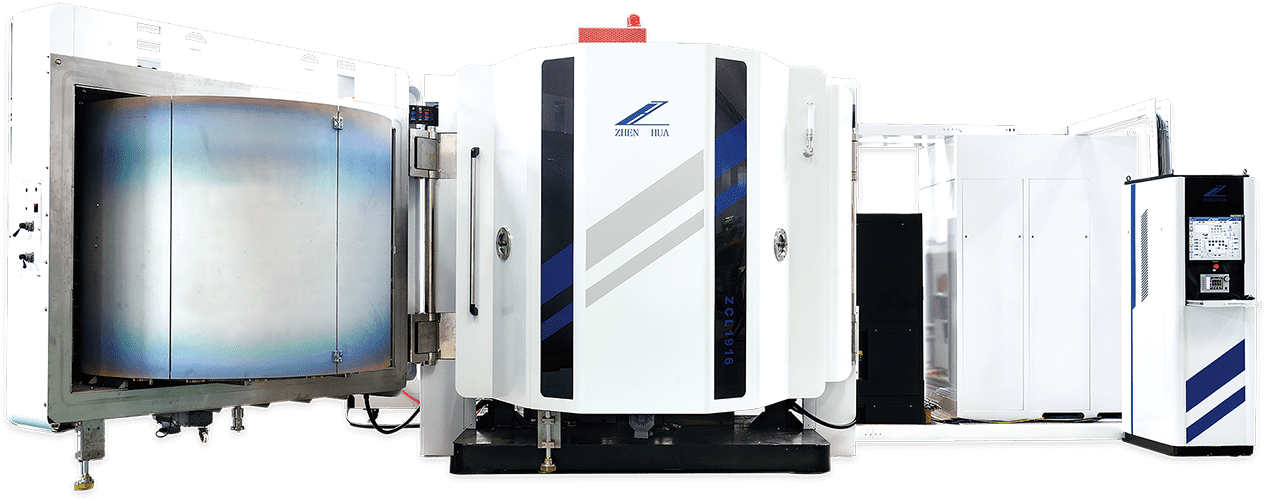

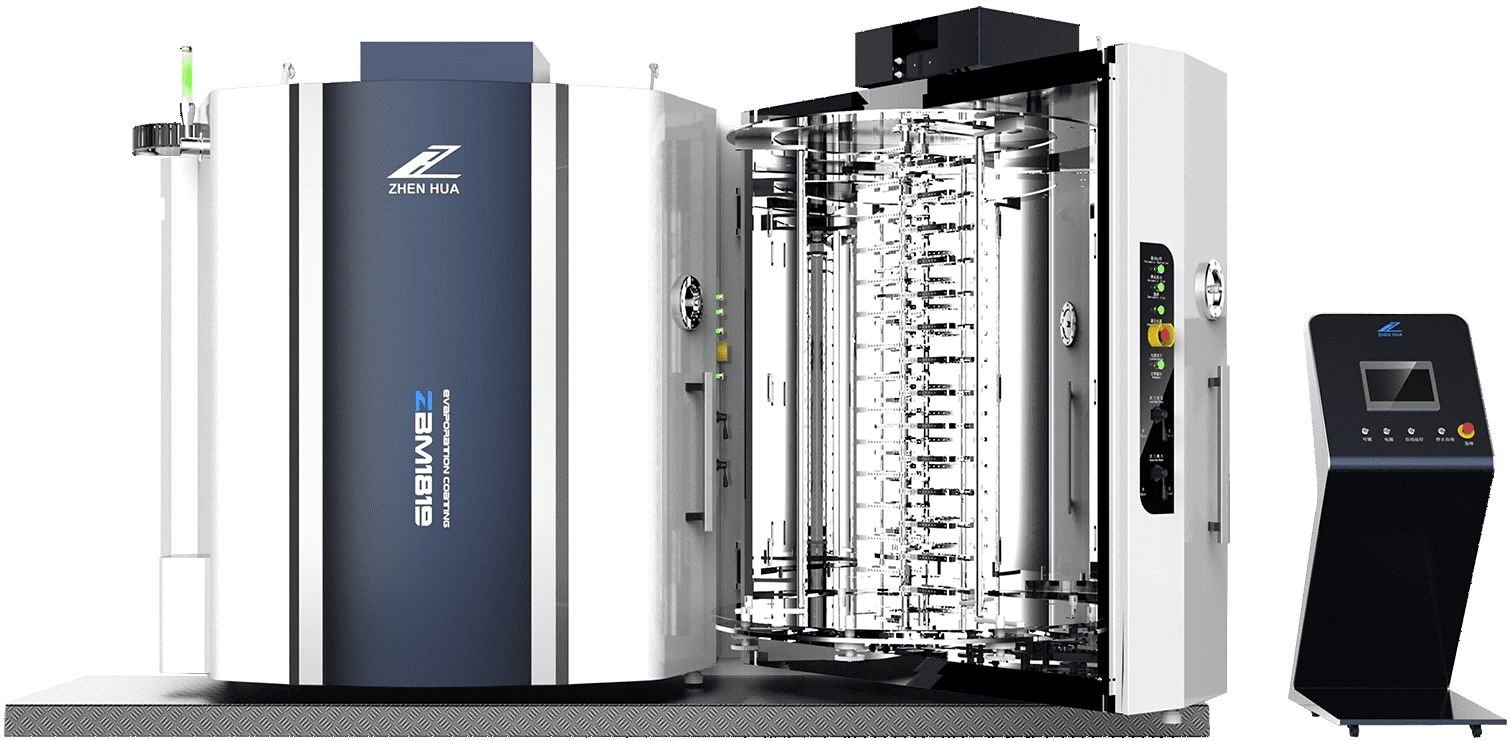

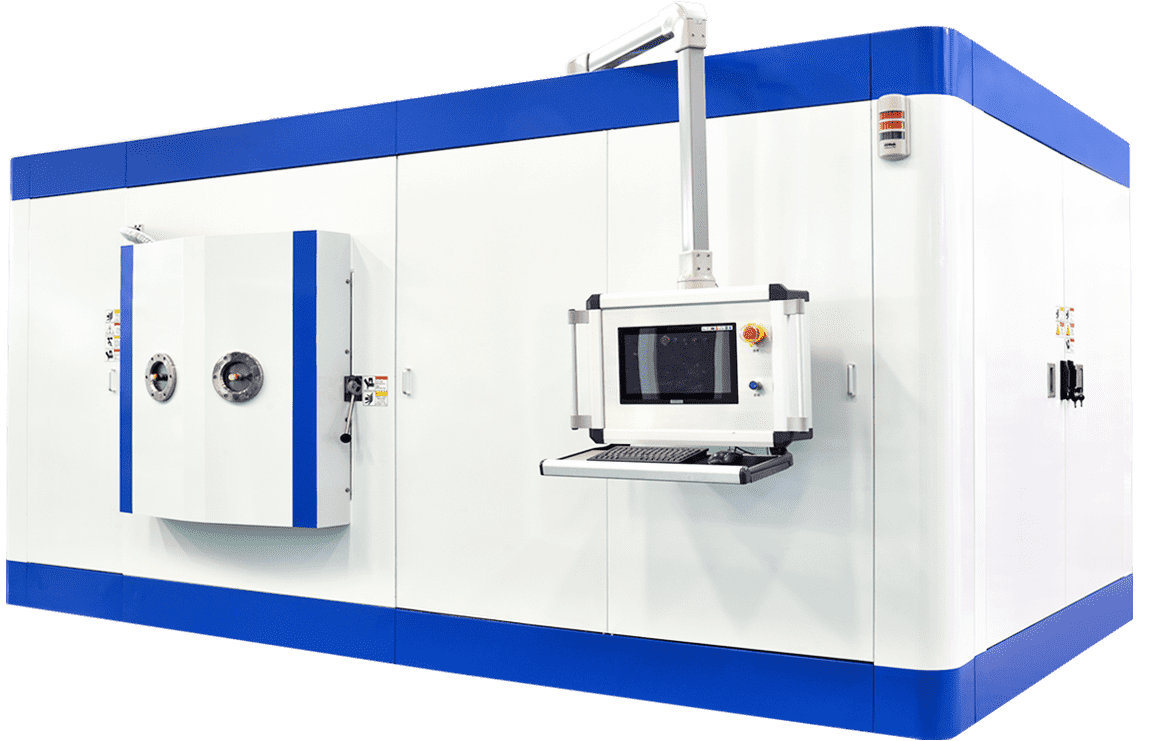

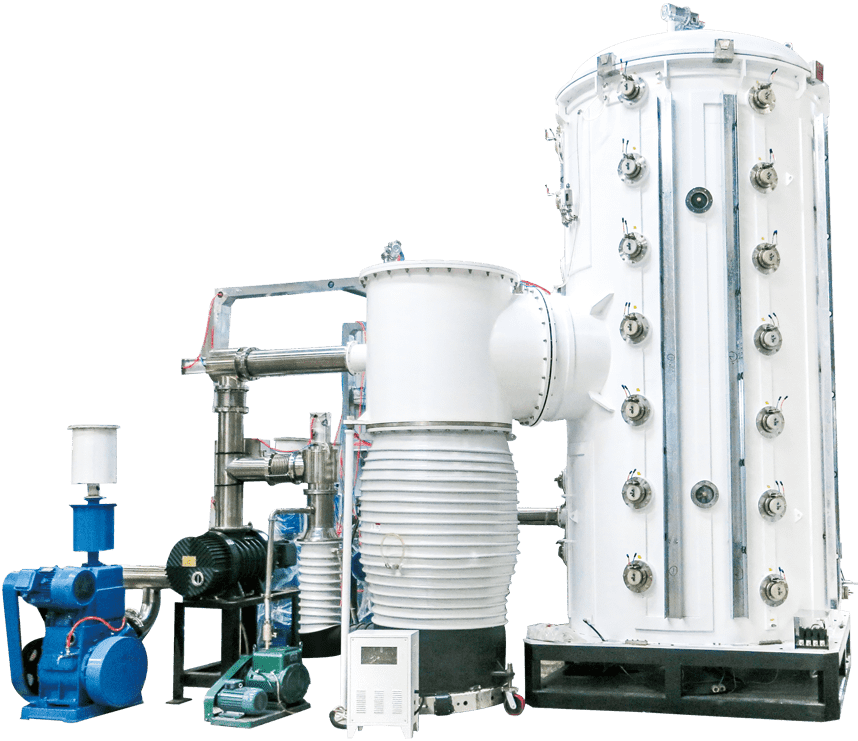

In the vacuum chamber, the coating material is vaporized and deposited on the substrate by using the resistance heating method, so that the surface of the substrate can obtain metal texture and achieve the purpose of decoration. It is characterized by fast film forming rate, bright color, high production efficiency, good film thickness uniformity and good film adhesion.

The evaporation coating equipment can be used to process ABS, PS, PP, PC, PVC, TPU, nylon, metal, glass, ceramics and other materials, and is suitable for evaporation coating of aluminum, chromium, indium, tin, indium tin alloy, silicon oxide, zinc sulfide and other materials. The equipment has been widely used in mobile phone plastic structural parts, smart home, digital products, cosmetics packaging, handicrafts, toys, wine packaging, electronic components and other products.

Optional models

| ZHL/FM1200 | ZHL/FM1400 | ZHL/FM1600 | ZHL/FM1800 |

| φ1200*H1500(mm) | φ1400*H1950(mm) | φ1600*H1950(mm) | φ1800*H1950(mm) |

| ZHL/FM2000 | ZHL/FM2022 | ZHL/FM2222 | ZHL/FM2424 |

| φ2000*H1950(mm) | φ2000*H2200(mm) | φ2200*H2200(mm) | φ2400*H2400(mm) |

PRODUCT FEATURE

INDUSTRY APPLICATION

RELATIVE DEVICES

Click ViewFactory directly Metal Vacuum Pvd Coating Machi...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

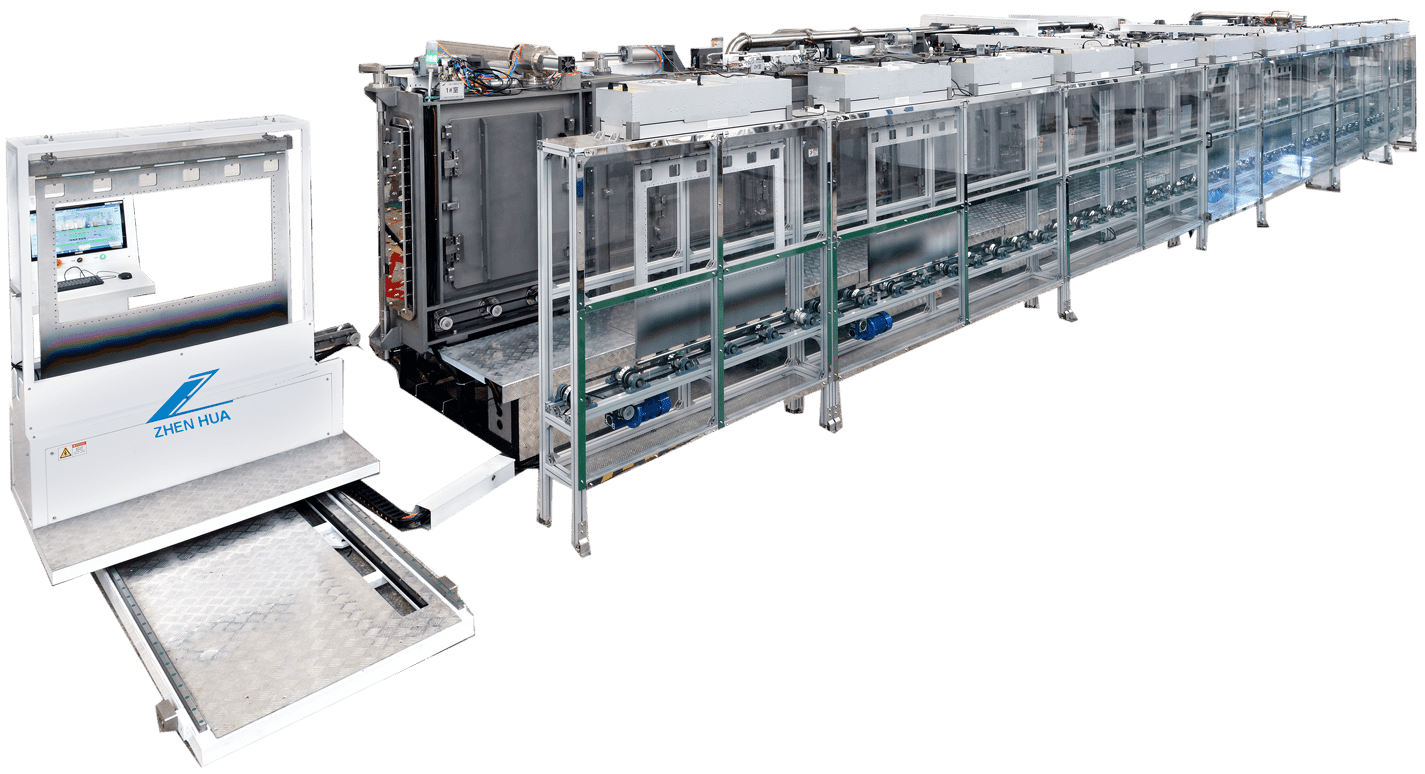

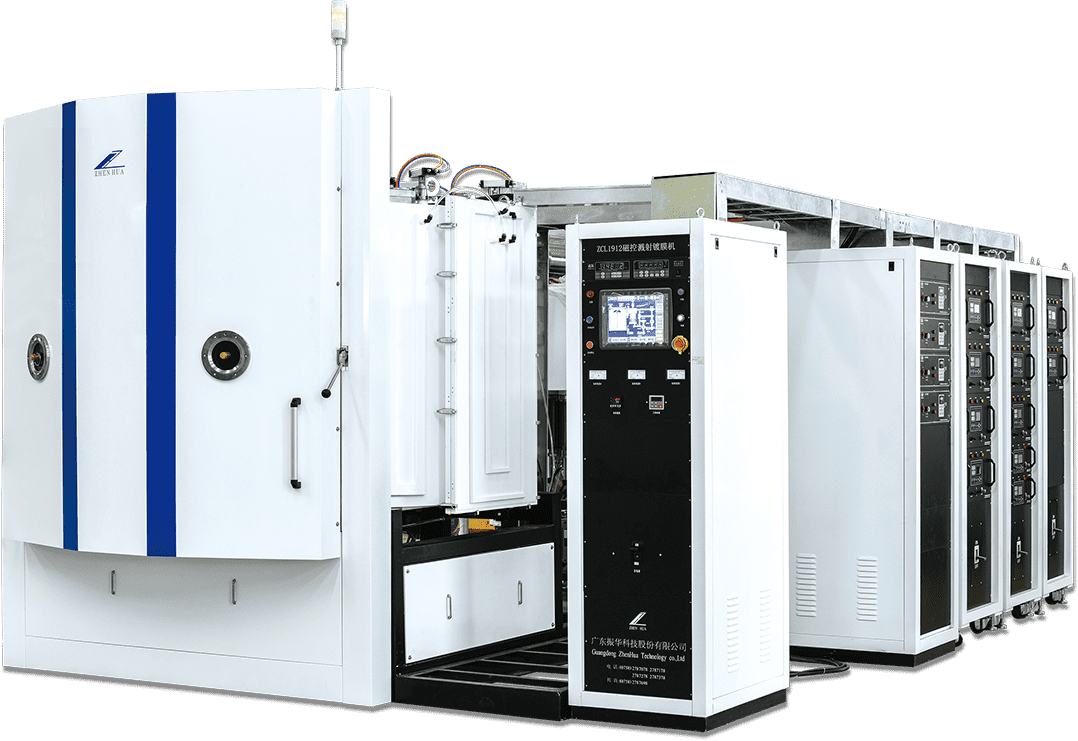

Hot-selling Al Coating - Double door magnetron...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

China OEM Mobile Phone Structure Coating Equipm...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Factory Outlets Photochromic Glass - Special m...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

Renewable Design for TOPCON Battery Coating Mac...

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

100% Original Factory Evaporation Magnetron Spu...

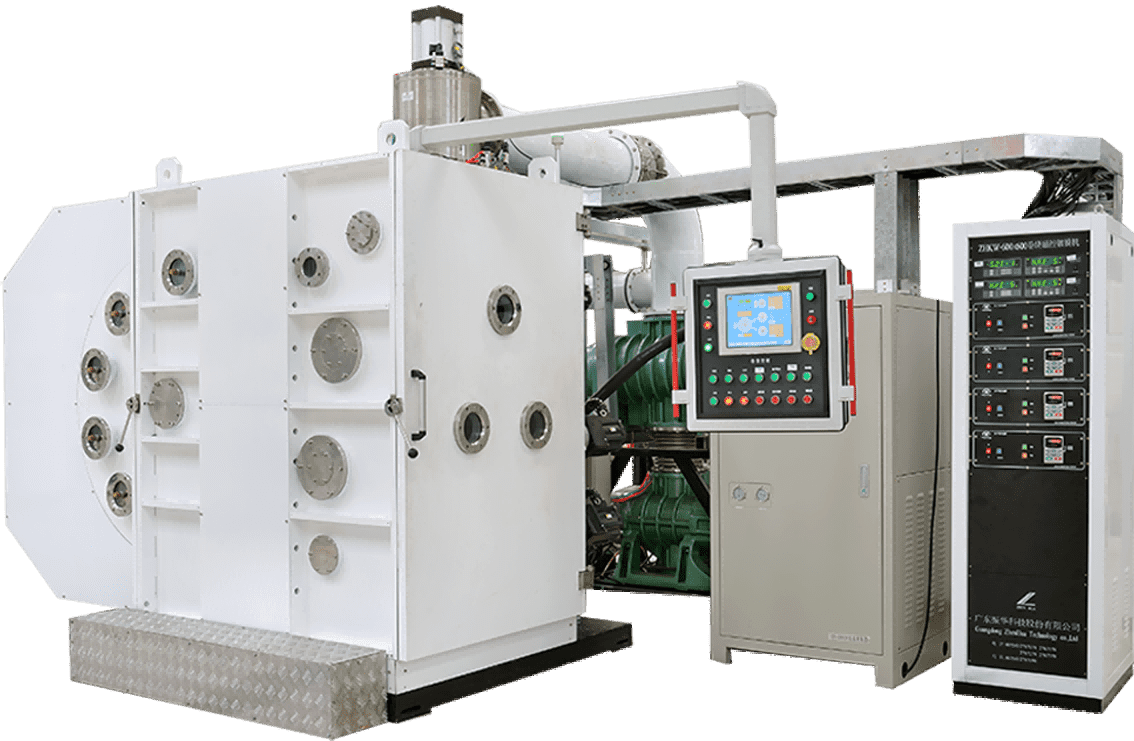

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

China Factory for Coating Of Mobile Phone Struc...

Sapphire film hard coating equipment is a professional equipment for depositing sapphire film. The equipment integrates three coating systems of medium frequency reactive magnetron sputtering + CVD...

Big Discount Pvd Chrome Equipment - Lamp prote...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Manufacturer of Easy To Clean AF Anti Fingerpri...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Good User Reputation for Pvd Plasma Coating Mac...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

PriceList for Vacuum Coating Machine - Vertic...

The coating line adopts vertical modular structure design and is equipped with multiple access doors, which is convenient for independent installation and maintenance of the cavity, assembly and fu...

Hot sale Vacuum Coating Machine For Glass - TG...

Equipment advantage 1. Deep Hole Coating Optimization Exclusive Deep Hole Coating Technology: Zhenhua Vacuum’s self-developed deep hole coating technology can achieve a superior aspect ratio ...

factory low price Car Lamp Thermal Evaporation ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Factory Outlets Bipolar Plate Platinum Coating ...

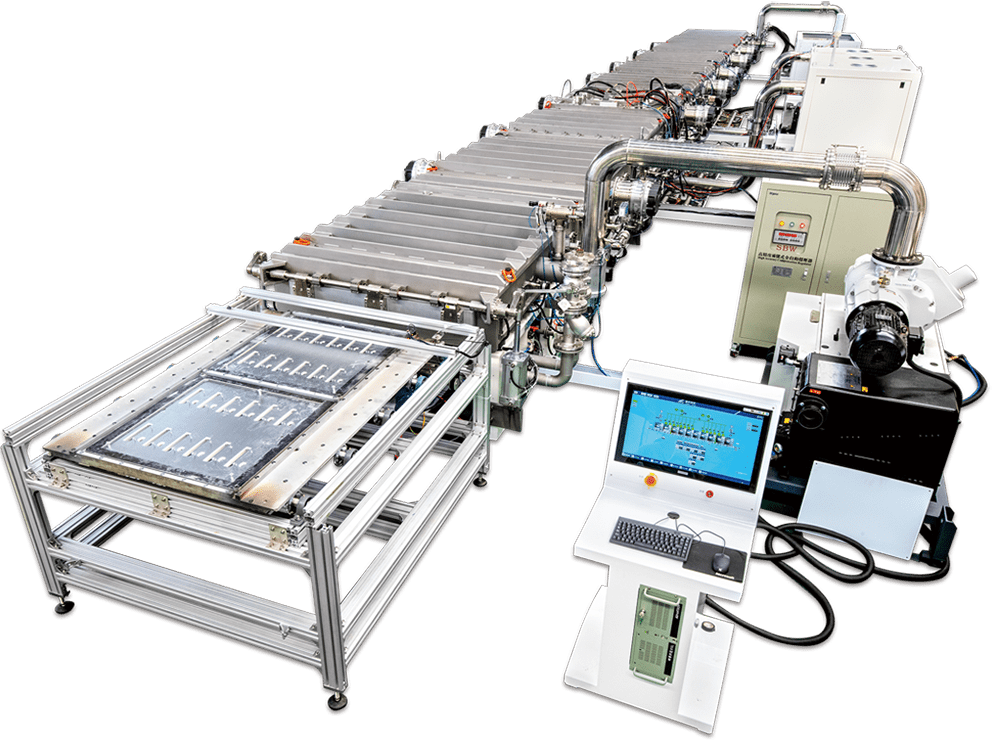

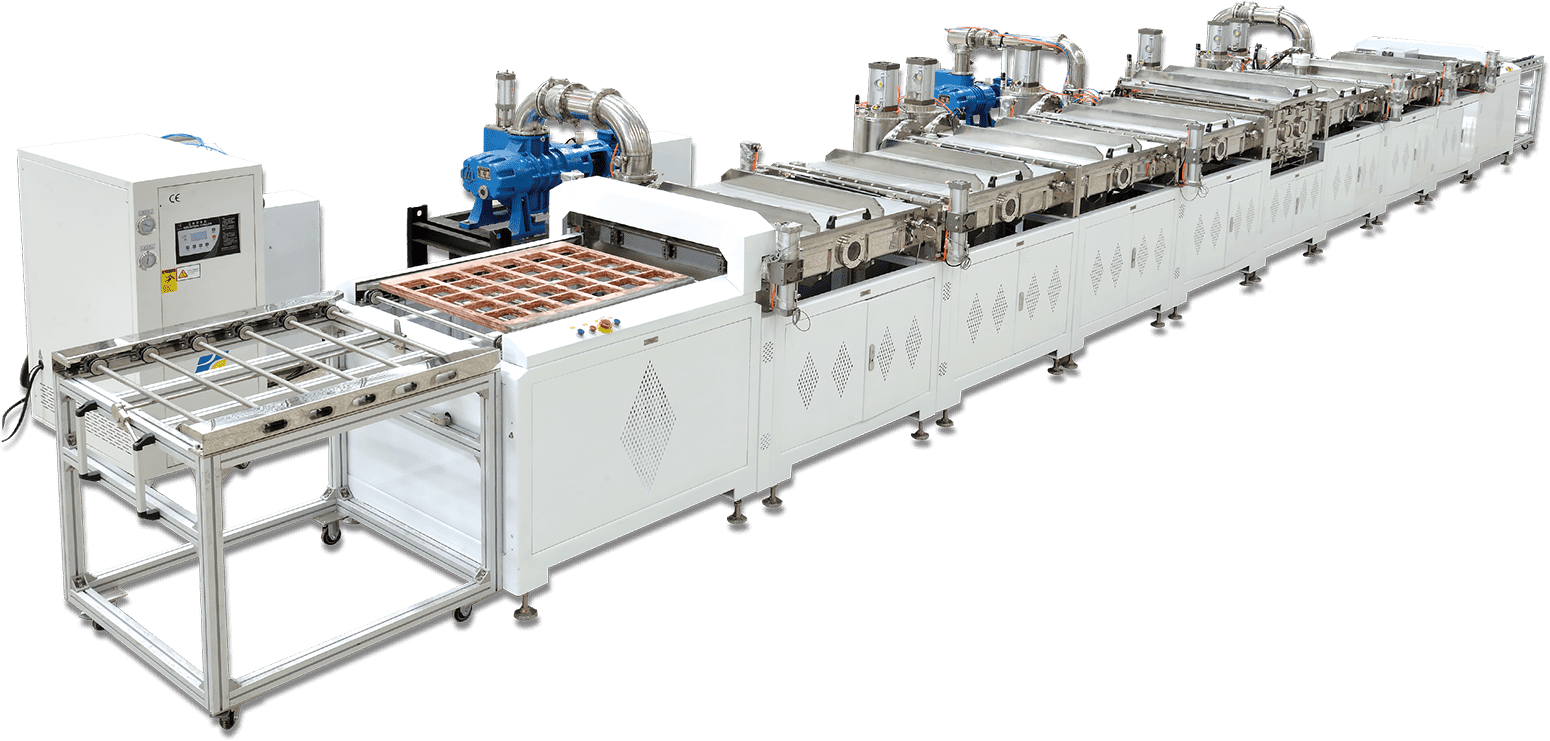

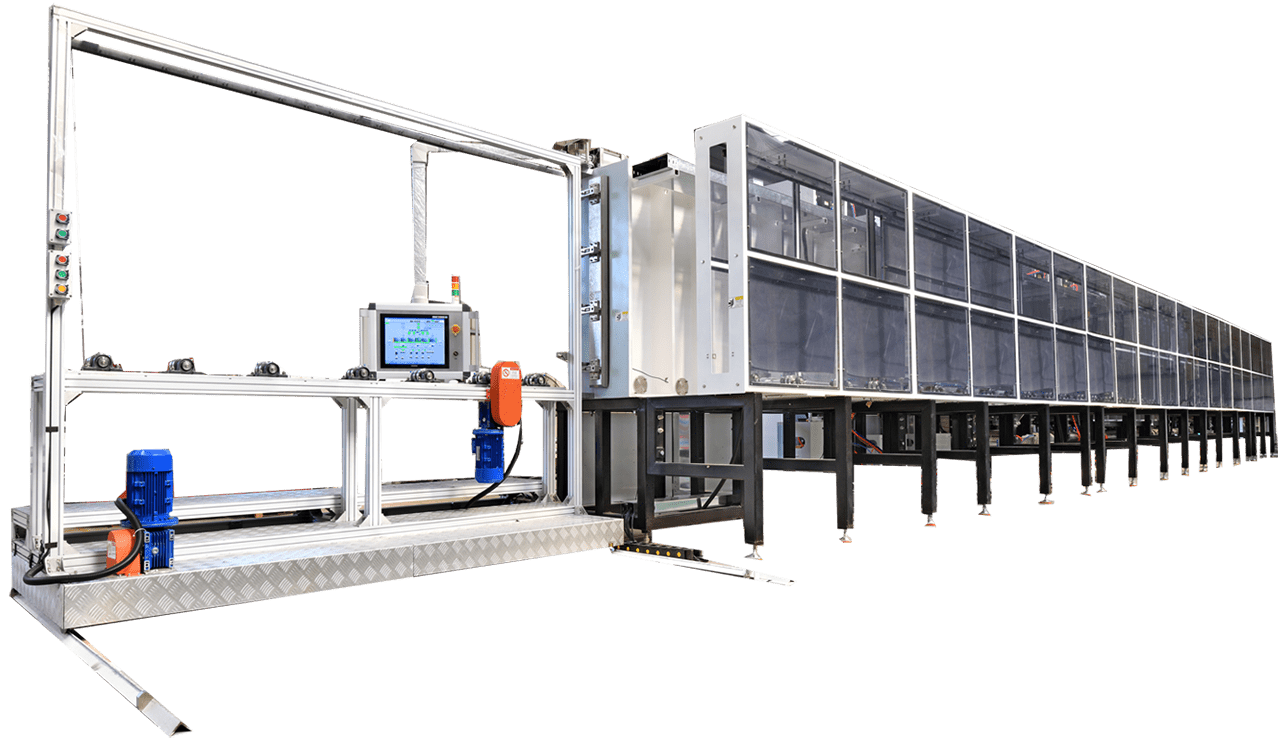

ITO / ISI horizontal continuous coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion and upgrad...

Online Exporter AF Coating Of Mobile Phone - I...

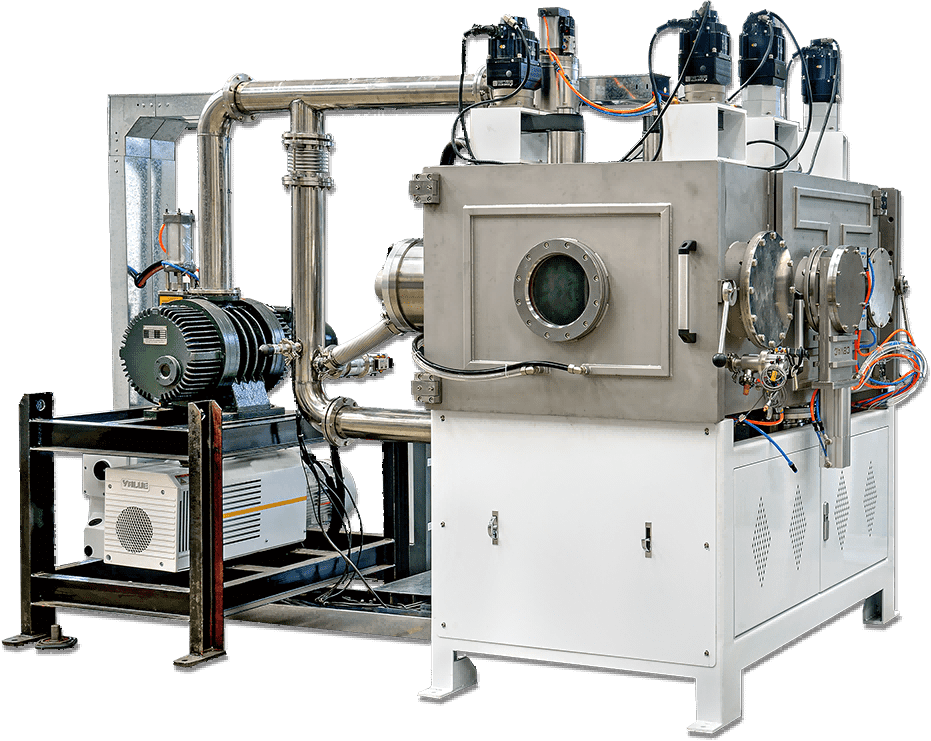

The equipment integrates magnetron sputtering and resistance evaporation technology, and provides a solution for coating a variety of different substrates. The experimental coating equipment is mai...

2022 wholesale price Pvd Vacuum Coating Equipme...

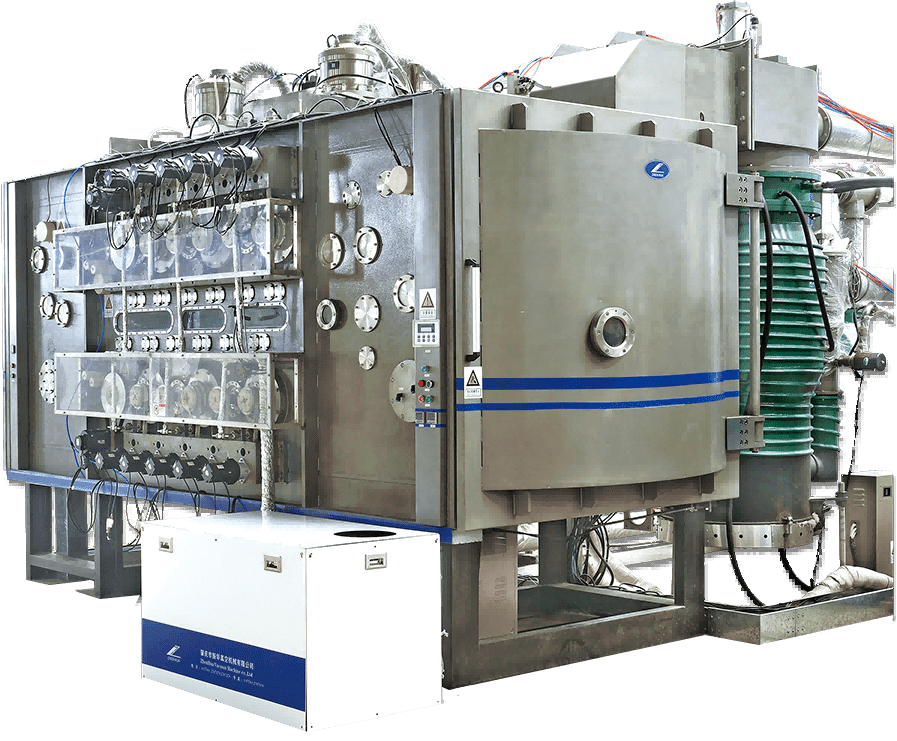

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Best-Selling Post Oxidation Coating - Vacuum p...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Massive Selection for Gold Sputtering Machine -...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Discountable price Pvd Coating Equipment Manufa...

ITO / ISI horizontal continuous coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion and upgrad...

Super Purchasing for Pvd Chrome Coating Equipme...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

China Factory for Coating Of Mobile Phone Struc...

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

Quality Inspection for Cutting Tools Vacuum Coa...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

OEM Supply Phone Back Cover Coating Machine - ...

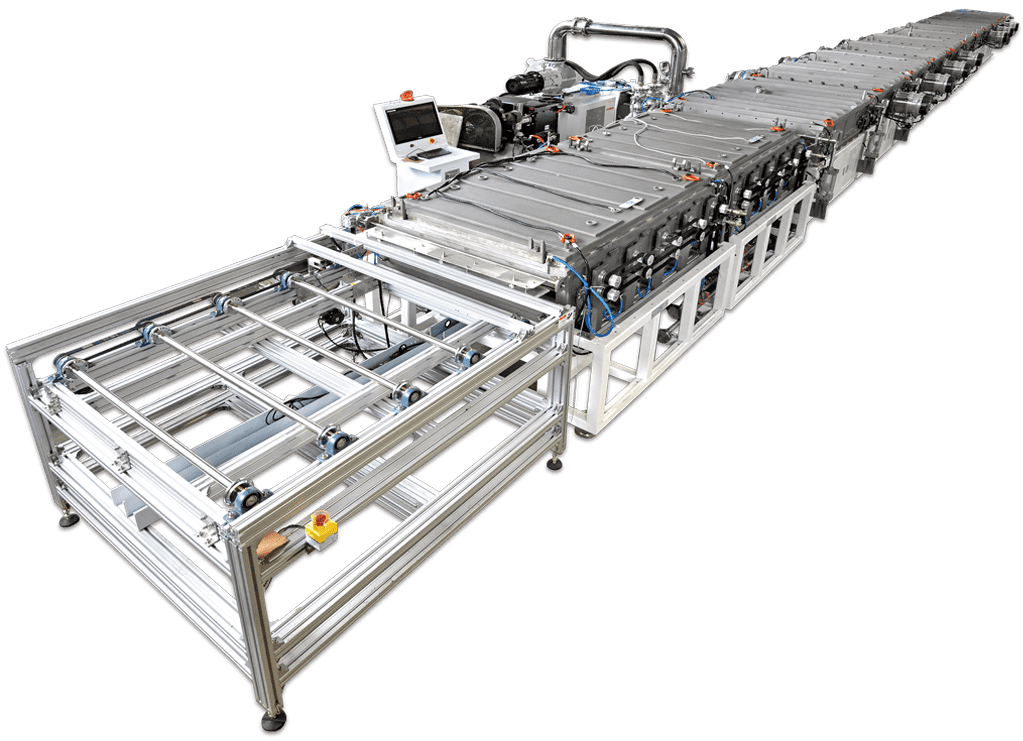

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Factory Outlets Bipolar Plate Platinum Coating ...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Low price for Nano Vacuum Coating Machine - La...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

2022 High quality Reflective Cup Coating Equipm...

In the vacuum chamber, the coating material is vaporized and deposited on the substrate by using the resistance heating method, so that the surface of the substrate can obtain metal texture and ach...

Factory Promotional Car Light Evaporation Coati...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Bottom price Hardware Decorative Coating Equipm...

The equipment integrates magnetron sputtering and ion coating technology, and provides a solution for improving color consistency, deposition rate and stability of compound composition. According t...

Factory source Jewelry Wear-Resistant Coating E...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

Leading Manufacturer for Pvd Coating Equipment ...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Wholesale Price Optical Film Coating Machine -...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Reasonable price for Vacuum Metalizing Machine ...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Manufacturer of Tin Pvd Coating Machine For Cer...

The equipment is equipped with magnetron sputtering coating system + anti fingerprint coating system + SPEEDFLO closed-loop control. The equipment adopts medium frequency magnetron sputtering techn...

Bottom price Pvd Equipment Italy - Magnetron S...

The equipment integrates magnetron sputtering and ion coating technology, providing a solution for improving color consistency, deposition rate and stability of compound composition. According to d...

factory Outlets for Sputtering Coating Equipmen...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Trending Products Chrome Pvd Coating Machine -...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Manufacturer for Vacuum Coating Equipment For S...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

Renewable Design for Ion Plasma Vacuum Coating ...

Vacuum plasma cleaning equipment adopts integrated structure, equipped with RF ion cleaning system, fully automatic control, convenient operation and maintenance. The RF high-frequency generator ca...

OEM Manufacturer Buy Vacuum Coating Machine - ...

In the vacuum chamber, the coating material is vaporized and deposited on the substrate by using the resistance heating method, so that the surface of the substrate can obtain metal texture and ach...

Manufacturing Companies for Multi Arc Ion Vacuu...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Hot sale Vacuum Coating Machine For Glass - Ha...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

China New Product Lithium Battery Compound Copp...

In the vacuum state, place the workpiece on the cathode of low-pressure glow discharge and inject appropriate gas. At a certain temperature, a coating is obtained on the surface of the workpiece by...

Factory directly Plasma Sputtering Machine - H...

The cathode of the equipment adopts the dual drive technology of front coil and permanent magnet superposition, and cooperates with the anode layer ion source etching system and three-dimensional m...

professional factory for Vacuum Evaporation Coa...

The coating line adopts modular structure, which can increase the chamber according to the process and efficiency requirements, and can be coated on both sides, which is flexible and convenient. Eq...

2022 China New Design Bipolar C Coating - Expe...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Excellent quality Decorative Vacuum Coating Mac...

The coating line adopts modular structure, which can increase the chamber according to the process and efficiency requirements, and can be coated on both sides, which is flexible and convenient. Eq...

Wholesale Vacuum Coating Equipment Germany - V...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Free sample for Mobile Camera Coating Machine -...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Wholesale Price Perovskite Battery - Large sca...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Wholesale Price China Vacuum Coating Equipment ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Wholesale Discount Pvd Coating Equipment Suppli...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Fixed Competitive Price Pvd Chrome Machine - S...

Sapphire film hard coating equipment is a professional equipment for depositing sapphire film. The equipment integrates three coating systems of medium frequency reactive magnetron sputtering + CVD...

Ordinary Discount Vacuum Sputtering Machine - ...

The equipment mainly adopts chemical vapor deposition to prepare oxide film, which has the characteristics of fast deposition rate and high film quality. As for the equipment structure, the double ...

China New Product Lithium Battery Compound Copp...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Hot sale Factory Backless Lamp Coating Equipmen...

The equipment integrates magnetron sputtering and ion coating technology. According to different product requirements, heating system, bias system, ionization system and other devices can be select...

Rapid Delivery for Pvd Metal Coating Equipment ...

The equipment is a vertical double door structure. It is a composite equipment integrating DC magnetron sputtering coating technology, resistance evaporation coating technology, CVD coating technol...

Original Factory Ion Plasma Vacuum Coating Mach...

With the rapid growth of mobile phone industry demand, the loading capacity of traditional optical coating machine can not meet this demand. ZHENHUA has launched magnetron sputtering optical coatin...

Wholesale Price China Vacuum Coating Equipment ...

The equipment integrates magnetron sputtering and ion coating technology, providing a solution for improving color consistency, deposition rate and stability of compound composition. According to d...

Reliable Supplier One Year Warranty Magnetron S...

The experimental roll to roll coating equipment adopts the coating technology combining magnetron sputtering and cathode arc, which meets the requirements of both film compactness and high ionizati...

Factory best selling Vacuum Coating Equipment P...

The large-scale anti fingerprint coating equipment for high-end sanitary ware is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerpr...

PriceList for Roll To Roll Coating Equipment -...

The equipment adopts multi arc ion coating technology, which has the advantages of simple operation, fast pumping speed, high efficiency and good process repeatability. It is equipped with a double...

Factory directly Plasma Sputtering Machine - V...

Optional models Vertical multifunctional coating production line Vertical decorative film coating production line

2022 China New Design Bipolar C Coating - Spec...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

High Quality Pvd Coating Machine - Special pro...

As the current market has higher and higher requirements for the wearability of jewelry, the company has launched special protective film equipment for the jewelry industry. The equipment adopts CV...

High Quality Dlc Coating Machine - Special har...

The equipment adopts cathode arc ion coating technology and is equipped with advanced IET etching system. After treatment, the product can directly deposit hard coating without transition layer. At...

Good Quality Pvd Machine - Magnetic filtering ...

With the rapid growth of the market demand for improving the wear resistance, lubrication, corrosion resistance and other properties of hard coatings, cathodic arc magnetic filtration ion coating e...

Free sample for Jewelry Wear-Resistant Coating ...

The coating line adopts modular structure, which can increase the chamber according to the process and efficiency requirements, and can be coated on both sides, which is flexible and convenient. Eq...

Factory wholesale Pvd Coating Equipment - GX60...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Hot Selling for HJT Battery Coating - Large ho...

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Factory Price Bipolar Plate Platinum Coating Eq...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Factory Cheap Lamp Coating Equipment - Special...

The CF1914 equipment is equipped with medium frequency magnetron sputtering coating system + anode layer ion source + SPEEDFLO closed-loop control + crystal control monitoring system. The medium fr...

Factory directly supply Car Light Thermal Evapo...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...

Manufacturer for Hard Film Vacuum Coating Machi...

The equipment integrates magnetron sputtering and ion coating technology, and provides a solution to improve color consistency, deposition rate and stability of compound composition with unique whe...

Reasonable price for Vacuum Metalizing Machine ...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Hot Sale for Rear View Mirror Chrome Plating -...

The lamp protective film equipment developed by ZHENHUA solves the long-standing problem that PC / ABS lamps need to be sprayed with paint. It allows the injection molded parts of the lamps to dire...

Manufacturing Companies for Multi Arc Ion Vacuu...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

Hot Sale for Bipolar Plate Anti-Corrosion Coati...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Factory Supply Pvd Mini Coating Equipment - Sp...

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is ...

New Arrival China Sputtering Equipment Manufact...

Sapphire film hard coating equipment is a professional equipment for depositing sapphire film. The equipment integrates three coating systems of medium frequency reactive magnetron sputtering + CVD...

professional factory for Vacuum Evaporation Coa...

The equipment adopts cathode arc ion coating technology and is equipped with advanced IET etching system. After treatment, the product can directly deposit hard coating without transition layer. At...

High Performance PCB Micro Drill Coating Equipm...

In the vacuum state, place the workpiece on the cathode of low-pressure glow discharge and inject appropriate gas. At a certain temperature, a coating is obtained on the surface of the workpiece by...

Big discounting Milling Cutter Coating Machine ...

The equipment adopts the electron beam evaporation technology. Electrons are emitted from the cathode filament and focused into a certain beam current, which is accelerated by the potential between...

100% Original Factory Car Light Pvd Coating Mac...

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stabl...

Discount wholesale Cvd Diamond Machine - Large...

The large horizontal magnetron sputtering coating production line is a large planar magnetron sputtering continuous production equipment, which adopts modular design to facilitate future expansion ...

Cheap PriceList for Sputtering Coating Machine ...

The large-scale metal anti fingerprint coating equipment is equipped with cathode arc ion coating system, medium frequency magnetron sputtering coating system and anti fingerprint coating system, w...