PRODUCT DESCRIPTION

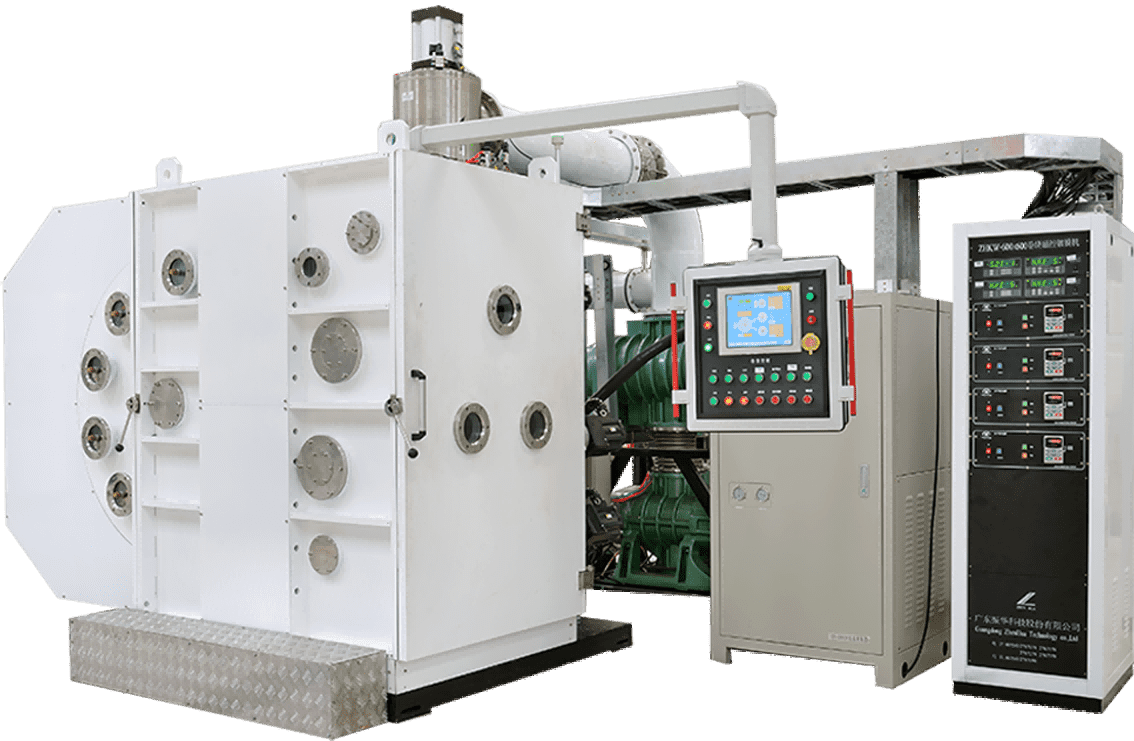

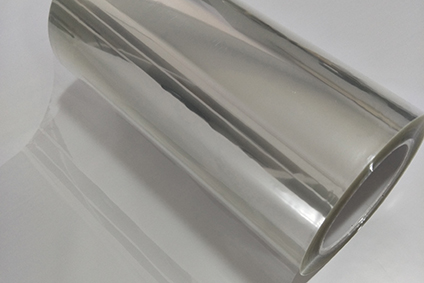

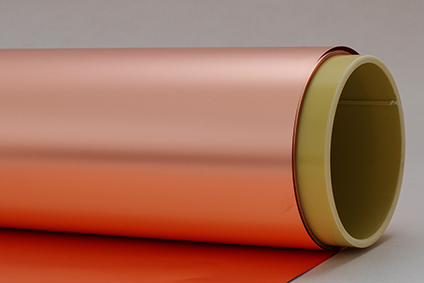

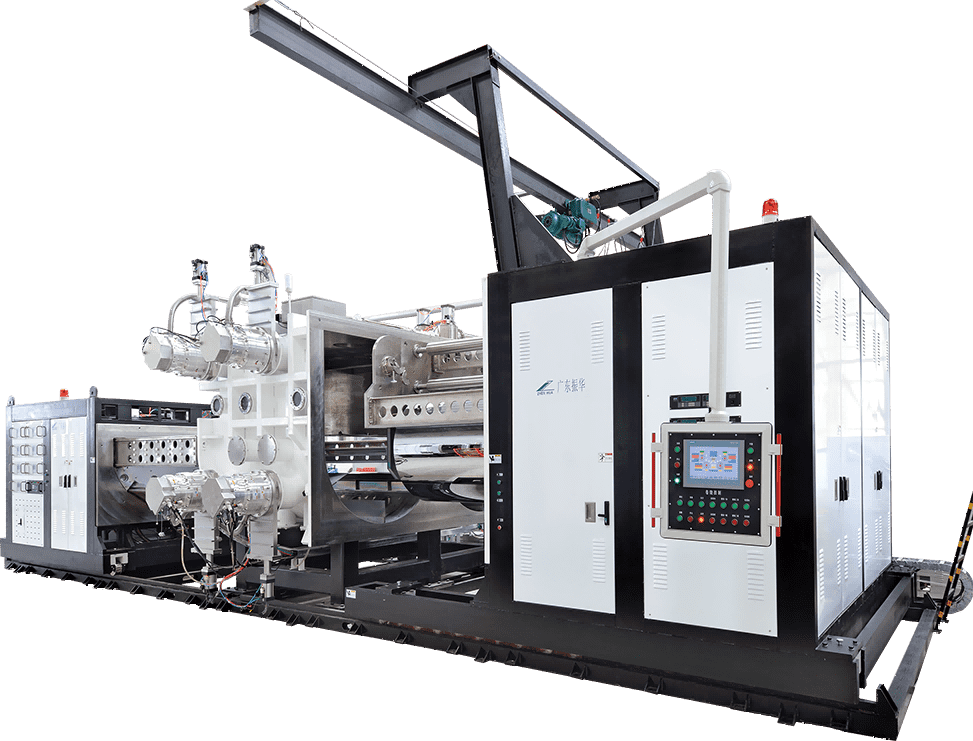

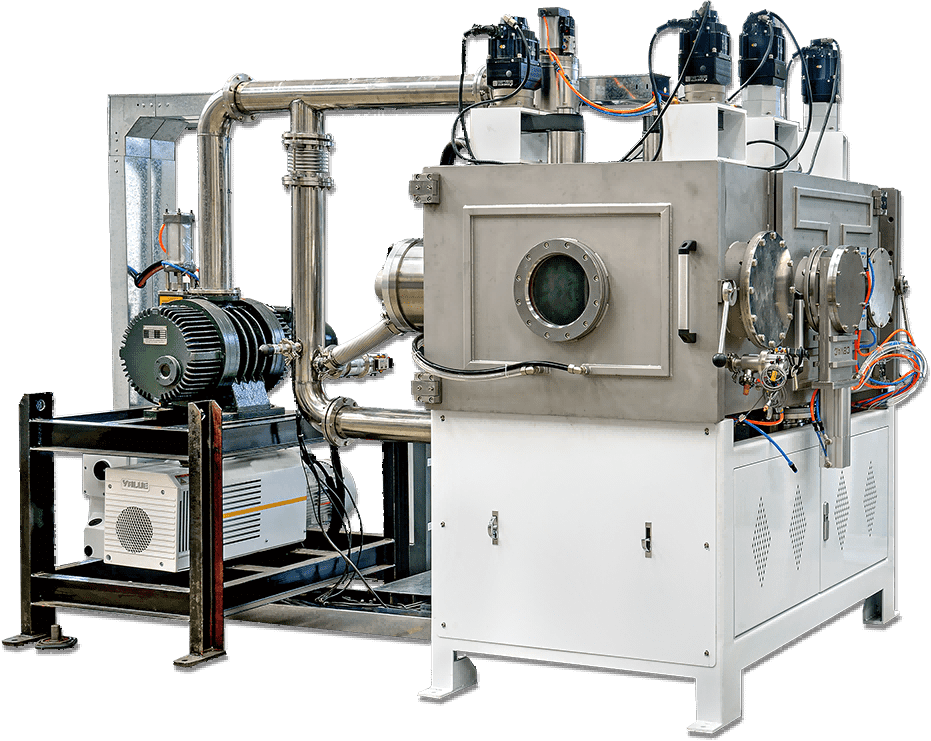

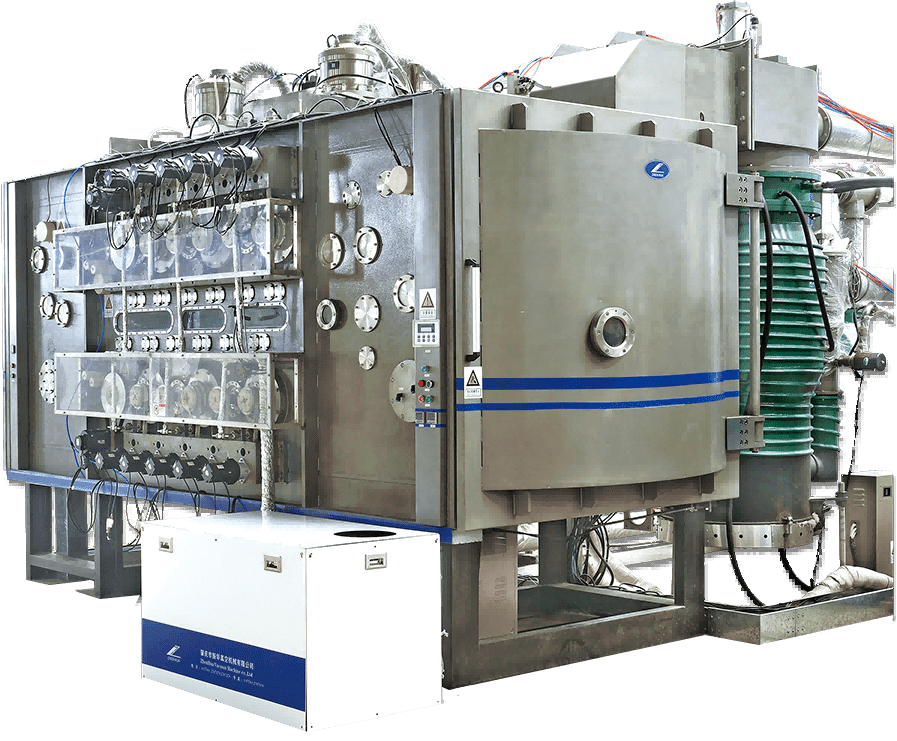

This series of equipment uses magnetron targets to convert coating materials into nanometer sized particles, which are deposited on the surface of substrates to form thin films. The rolled film is placed in the vacuum chamber. Through the electrically driven winding structure, one end receives the film and the other puts the film. It continues to pass through the target area and receives the target particles to form a dense film.

Characteristic:

1. Low temperature film forming. The temperature has little effect on the film and will not produce deformation. It is suitable for PET, PI and other base material coil films.

2. The film thickness can be designed. Thin or thick coatings can be designed and deposited by process adjustment.

3. Multiple target location design, flexible process. The whole machine can be equipped with eight targets, which can be used as either simple metal targets or compound and oxide targets. It can be used to prepare single-layer films with single structure or multi-layer films with composite structure. The process is very flexible.

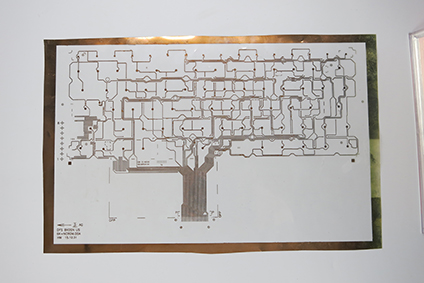

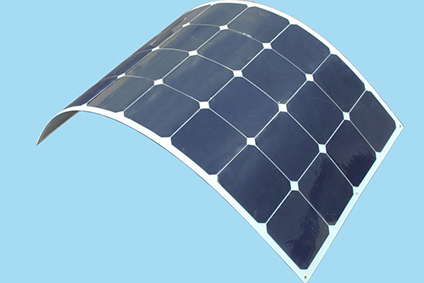

The equipment can prepare electromagnetic shielding film, flexible circuit board coating, various dielectric films, multi-layer AR antireflection film, HR high antireflection film, color film, etc. the equipment has a very wide range of applications, and single-layer film deposition can be completed by one-time film deposition.

The equipment can adopt simple metal targets such as Al, Cr, Cu, Fe, Ni, SUS, TiAl, etc., or compound targets such as SiO2, Si3N4, Al2O3, SnO2, ZnO, Ta2O5, ITO, AZO, etc.

The equipment is small in size, compact in structure design, small in floor area, low in energy consumption, and flexible in adjustment. It is very suitable for process research and development or small batch mass production.