1. Bombardment hloekisa substrate

1.1) Mochini oa ho roala o sebelisa mokelikeli o khanyang ho hloekisa substrate. Ka mantsoe a mang, lefisa khase ea argon ka phaposing, motlakase oa ho lahla o haufi le 1000V, Kamora ho bulela phepelo ea motlakase, ho hlahisoa phallo e khanyang, 'me substrate e hloekisoa ke bombardment ea argon ion.

1.2) Mechineng ea ho roala metsi e hlahisang mekhabiso e phahameng indastering, li-ion tsa titanium tse hlahisoang ke mehloli e menyenyane ea li-arc li sebelisoa haholo ho hloekisa. Mochini oa ho roala li-sputtering o na le mohloli o monyenyane oa arc, 'me phallo ea titanium ion ka har'a plasma ea arc e hlahisoang ke ho tsoa ha mohloli o monyenyane oa arc e sebelisetsoa ho bombard le ho hloekisa substrate.

2. Ho roala ha titanium nitride

Ha u beha lifilimi tse tšesaane tsa titanium nitride, thepa e reretsoeng ho sputtering ke sepheo sa titanium. Thepa e reretsoeng e hokahane le eleketrode e mpe ea phepelo ea matla a sputtering, 'me matla a sepheo ke 400 ~ 500V; The argon flux e tsitsitse, 'me vacuum ea taolo ke (3 ~ 8) x10-1PA. Substrate e hokahane le electrode e mpe ea phepelo ea matla a leeme, e nang le voltage ea 100 ~ 200V.

Ka mor'a ho bulela phepelo ea matla ea sepheo sa sputtering titanium, ho hlajoa ke khanya e khanyang, 'me li-ion tsa argon tse matla haholo li hlasela sepheo sa sputtering, ho fafatsa liathomo tsa titanium ho tloha moo ho shebiloeng.

Phello ea khase ea naetrojene e hlahisoa, 'me liathomo tsa titanium le naetrojene li kenngoa ka li-ion tsa titanium le li-ion tsa naetrojene ka kamoreng ea ho roala. Tlas'a ho hoheloa ke leeme le leeme tšimo ea motlakase e sebelisoang karolong e ka tlaase, li-ion tsa titanium le li-ion tsa naetrojene li potlakisa holim'a karoloana bakeng sa karabelo ea lik'hemik'hale le ho beoa ho etsa lera la filimi ea titanium nitride.

3. Ntša substrate

Kamora ho fihla botenya ba filimi e reriloeng esale pele, tima phepelo ea motlakase ea sputtering, phepelo ea motlakase ea leeme la substrate, le mohloli oa moea. Kamora hore mocheso oa substrate o be tlase ho 120 ℃, tlatsa kamore ea ho roala ka moea ebe o ntša substrate.

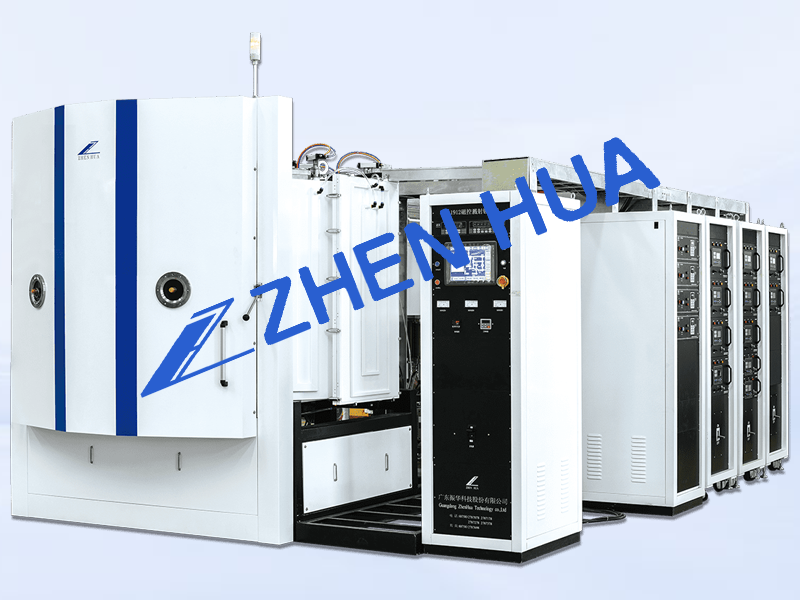

Sengoliloeng sena se hatisitsoe kemoetsi oa mochini oa ho roala oa magnetron sputtering– Guangdong Zhenhua.

Nako ea poso: Apr-07-2023