1. Likarolo tsa ho roala sputter

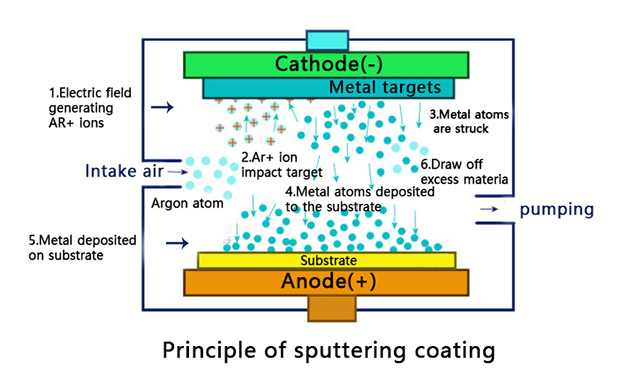

Ha ho bapisoa le seaparo se tloaelehileng sa vacuum evaporation, seaparo sa sputtering se na le likarolo tse latelang:

(1) Ntho leha e le efe e ka qhaqhoa, haholo-holo sebaka se phahameng sa ho qhibiliha, likarolo tse tlaase tsa khatello ea mouoane le metsoako. Hafeela e ntse e tiile, ebang ke tšepe, semiconductor, insulator, motsoako le motsoako, joalo-joalo, ebang ke block, granular material e ka sebelisoa e le thepa e reretsoeng. Kaha ho senyeha ho honyenyane le ho arohana ho etsahala ha ho fafatsa thepa e sireletsang le lialloys tse kang oxides, li ka sebelisoa ho lokisetsa lifilimi tse tšesaane le li-alloy tse nang le likaroloana tse tšoanang le tsa thepa e lebisitsoeng, esita le lifilimi tse phahameng ka ho fetisisa tse nang le lihlopha tse rarahaneng. li-silicone.

(2) Ho khomarela hantle pakeng tsa filimi e hlabang le substrate. Kaha matla a liathomo tse hahelletsoeng ke liodara tse 1-2 tsa boholo bo holimo ho feta a liathomo tse hahelletsoeng, phetolo ea matla ea likaroloana tse matla tse behiloeng holim'a substrate e hlahisa matla a phahameng a mocheso, a matlafatsang ho khomarela ha liathomo tse hahelletsoeng ho substrate. Karolo e 'ngoe ea liathomo tse nang le matla a phahameng a matla a tla kenngoa ka likhato tse sa tšoaneng, ho etsa seo ho thoeng ke pseudo-diffusion lera holim'a substrate moo liathomo tse phunyeletsoeng le liathomo tsa thepa ea substrate "miscible" hammoho. Ho phaella moo, nakong ea ho phatloha ha likaroloana tsa sputtering, substrate e lula e hloekisoa 'me e kenngoa sebakeng sa plasma, e tlosang liathomo tse sa khomaretsoeng hantle, e hloekisa le ho kenya letsoho holim'a metsi. Ka lebaka leo, ho khomarela lera la filimi e sputtered ho substrate ho ntlafatsoa haholo.

3

(4) Ho laola hantle le ho pheta-pheta ha botenya ba filimi. Kaha mocheso oa hona joale le sepheo sa hona joale se ka laoloa ka thoko nakong ea ho roala ha sputter, botenya ba filimi bo ka laoloa ka ho laola sepheo sa hona joale, ka hona, taolo ea botenya ba filimi le ho ikatisa ha botenya ba filimi ka ho hlajoa ka makhetlo a mangata ka ho roala ha sputter ho molemo, 'me filimi ea botenya bo reriloeng esale pele e ka koaheloa ka katleho. Ho phaella moo, ho roala ha sputter ho ka fumana botenya ba filimi e lekanang sebakeng se seholo. Leha ho le joalo, bakeng sa theknoloji ea ho roala ka kakaretso ea sputter (haholo-holo dipole sputtering), thepa e rarahane ebile e hloka sesebelisoa sa khatello e phahameng; lebelo la ho bopa filimi ea sputter deposition le tlase, sekhahla sa ho behoa ha mouoane oa vacuum ke 0.1 ~ 5nm / min, ha sekhahla sa sputtering ke 0.01 ~ 0.5nm / min; ho phahama ha mocheso oa substrate ho phahame 'me ho kotsing ea khase e sa hloekang, joalo-joalo. Leha ho le joalo, ka lebaka la nts'etsopele ea thekenoloji ea RF sputtering le magnetron sputtering, tsoelo-pele e kholo e fumanoe ho finyella ho behoa ha metsi ka potlako le ho fokotsa mocheso oa substrate. Ho feta moo, lilemong tsa morao tjena, ho ntse ho phenyekolloa mekhoa e mecha ea ho roala sputter - e thehiloeng ho planar magnetron sputtering - ho fokotsa khatello ea moea ea sputtering ho fihlela khatello ea zero-pressure sputtering moo khatello ea khase e kenang nakong ea sputtering e tla ba zero.

Nako ea poso: Nov-08-2022