In fact, Ion beam assisted deposition technology is a composite technology. It is a composite surface ion treatment technique combining ion implantation and physical vapor deposition film technology, and a new type of ion beam surface optimization technique. In addition to the advantages of physical vapor deposition, this technique can continuously grow any thickness film under more stringent control conditions, improve the crystallinity and orientation of the film layer more significantly, increase the adhesion strength of the film layer/substrate, improve the denseness of the film layer, and synthesize compound films with ideal stoichiometric ratios at near room temperature, including new types of films that cannot be obtained at room temperature and pressure. Ion beam assisted deposition not only retains the advantages of the ion implantation process, but can also cover the substrate with a completely different film from the substrate.

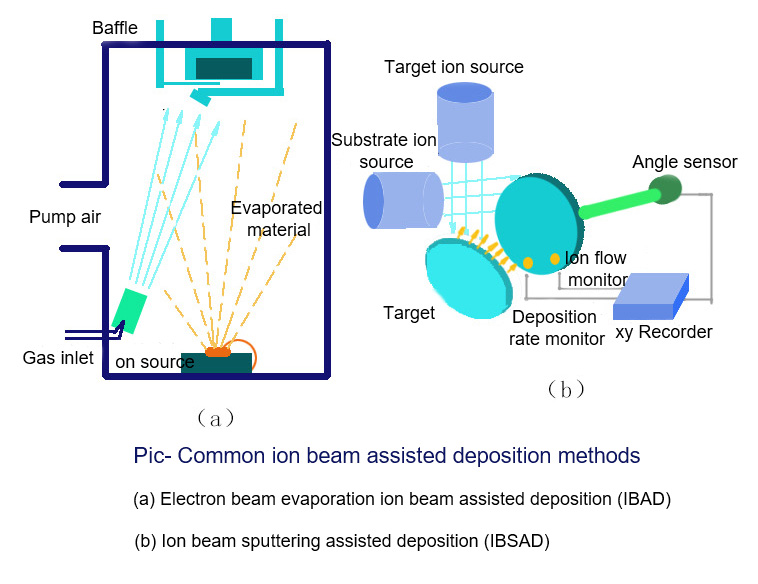

In all kinds of physical vapor deposition and chemical vapor deposition, a set of auxiliary bombardment ion guns can be added to form an IBAD system, and there are two general IBAD processes as follows, as shown in the Pic:

As shown in Pic (a), an electron beam evaporation source is used to irradiate the film layer with the ion beam emitted from the ion gun, thus realizing ion beam assisted deposition. The advantage is that the ion beam energy and direction can be adjusted, but only a single or limited alloy, or compound can be used as the evaporation source, and the each vapor pressure of the alloy component and compound is different, which makes it difficult to obtain the film layer of the original evaporation source composition.

Pic (b) shows the ion beam sputtering-assisted deposition, which is also known as double ion beam sputtering deposition, in which the target made of ion beam sputtering coating material, the sputtering products is used as the source. While depositing it on the substrate, ion beam sputtering assisted deposition is achieved by irradiation with another ion source. The advantage of this method is that the sputtered particles themselves have a certain energy, so there is better adhesion with the substrate; any component of the target can be sputtered coating, but also can be reaction sputtering into the film, easy to adjust the composition of the film, but its deposition efficiency is low, the target is expensive and there are problems such as selective sputtering.

Post time: Nov-08-2022