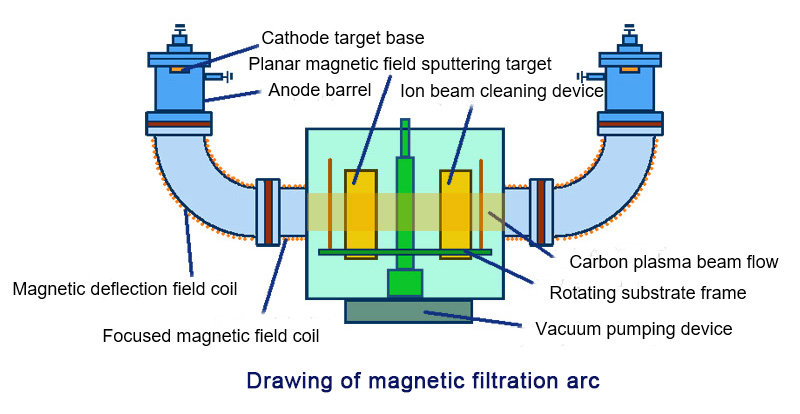

Basic theory of magnetic filtration device

The filtering mechanism of the magnetic filtering device for large particles in the plasma beam is as follows:

Using the difference between plasma and large particles in charge and charge-to-mass ratio, there is a “barrier” (either a baffle or a curved tube wall) placing between the substrate and the cathode surface, which blocks any particles moving in a straight line between the cathode and the substrate, while the ions can be deflected by the magnetic field and pass through the “barrier” to the substrate.

Working principle of magnetic filtration device

In the magnetic field, Pe<<a<Pi.

Pe and Pi are the Larmor radii of electrons and ions respectively, and a is the inner diameter of the magnetic filter. The electrons in the plasma are affected by the Lorentz force and spin along the magnetic field axially, while the magnetic field has less effect on the ions’ clustering due to the difference between the ions and electrons in the Larmor radius. However, when the electron movement along the axis of the magnetic filter device, it will attract ions along the axial for the rotational motion due to its focus and the strong negative electric field, and the electron speed is greater than the ion, so the electron constantly pull the ion forward, while the plasma always remains quasi-electrically neutral. The large particles are electrically neutral or slightly negatively charged, and the quality is much larger than the ions and electrons, basically not affected by the magnetic field and linear motion along the inertia, and will be filtered out after collision with the inner wall of the device.

Under the combined function of the bending magnetic field curvature and gradient drift and ion-electron collisions, the plasma can be deflected in the magnetic filtration device. In The common theoretical models used today are the Morozov flux model and the Davidson rigid rotor model, which have the following common feature: there is a magnetic field that makes the electrons move in a strictly helical manner.

The strength of the magnetic field guiding the axial motion of the plasma in the magnetic filtration device should be such that:

Mi, Vo, and Z are the ion mass, the transport velocity, and the number of charges carried respectively. a is the inner diameter of the magnetic filter, and e is the electron charge.

It should be noted that some higher energy ions cannot be fully bound by the electron beam. They may reach the inner wall of the magnetic filter, making the inner wall at a positive potential, which in turn inhibits the ions from continuing to reach the inner wall and reduces the loss of plasma.

According to this phenomenon, an appropriate positive bias pressure can be applied to the wall of the magnetic filter device to inhibit the collision of ions to improve the target ion transport efficiency.

Classification of magnetic filtration device

(1)Linear structure. The magnetic field acts as a guide for the ion beam flow, reducing the size of the cathode spot and the proportion of macroscopic particle clusters, while intensifying the collisions within the plasma, prompting the conversion of neutral particles into ions and reducing the number of macroscopic particle clusters, and rapidly reducing the number of large particles as the magnetic field strength increases. Compared with the conventional multi-arc ion coating method, this structured device overcomes the significant reduction in efficiency caused by other methods and can ensure essentially constant film deposition rate while reducing the number of large particles by about 60%.

(2) Curve-type structure. Although the structure has various forms, but the basic principle is the same. The plasma moves under the combined function of magnetic field and electric field, and the magnetic field is used to confine and control the plasma without deflecting motion along the direction of magnetic force lines. And the uncharged particles will move along the linear and be separated. The films prepared by this structural device have high hardness, low surface roughness, good density, uniform grain size, and strong film base adhesion. XPS analysis shows that the surface hardness of ta-C films coated with this type of device can reach 56 GPa, thus the curved structure device is the most widely used and effective method for large particle removal, but the target ion transport efficiency needs to be further improved. The 90° bend magnetic filtration device is one of the most widely used curved structure devices. Experiments on the surface profile of Ta-C films show that the surface profile of 360° bend magnetic filtration device does not change much compared with 90° bend magnetic filtration device, so the effect of 90° bend magnetic filtration for large particles can be basically achieved. 90° bend magnetic filtration device mainly has two types of structures: one is a bend solenoid placed in the vacuum chamber, and the other is placed out of the vacuum chamber, and the difference between them is only in the structure. The working pressure of 90° bend magnetic filtration device is in the order of 10-2Pa, and it can be used in a wide range of applications, such as coating nitride, oxide, amorphous carbon, semiconductor film and metal or non-metal film.

The efficiency of magnetic filtration device

Since not all large particles can lose kinetic energy in continuous collisions with the wall, a certain number of large particles will reach the substrate through the pipe outlet. Therefore, a long and narrow magnetic filtration device has a higher filtration efficiency of large particles, but at this time it will increase the loss of target ions and at the same time increase the complexity of the structure. Therefore, ensuring that the magnetic filtration device has excellent large particle removal and high efficiency of ion transport is a necessary prerequisite for multi-arc ion coating technology to have a wide application prospect in depositing high performance thin films. The operation of the magnetic filtration device is affected by the magnetic field strength, bend bias, mechanical baffle aperture, arc source current and charged particle incidence angle. By setting reasonable parameters of the magnetic filtration device, the filtering effect of large particles and the ion transfer efficiency of the target can be effectively improved.

Post time: Nov-08-2022