Хуш омадед ба Guangdong Zhenhua Technology Co.,Ltd.

Ахбор

-

Намудҳои технологияи CVD

Ба таври васеъ гӯем, CVD-ро тақрибан ба ду намуд тақсим кардан мумкин аст: яке дар як маҳсулот дар қабати буғи қабати эпитаксиалии яккристалл, ки ба таври танг CVD аст; дигараш дар руи замин гузоштани плёнкахои тунук, аз чумла плёнкахои сермахсул ва аморфй. Мувофиқи т...Бештар -

Спектрҳои интиқол ва инъикос ва ранги филмҳои тунуки оптикӣ Боби 2

Аз ин рӯ, мо бояд равшан кунем: (1) дастгоҳҳои тунук, гузаранда, спектрҳои инъикос ва ранги муносибати мувофиқи байни, яъне спектри ранг; баръакс, ин муносибат «бехамто нест», хамчун ранга бисьёр спектр зохир мегардад. Аз ин рӯ, филми "...Бештар -

Спектрҳои интиқол ва инъикос ва ранги филмҳои тунуки оптикӣ Боби 1

Спектрҳои интиқол ва инъикос ва рангҳои филмҳои тунуки оптикӣ ду хусусияти дастгоҳҳои филми тунук мебошанд, ки дар як вақт мавҷуданд. 1. Спектри интиқол ва инъикос муносибати байни инъикос ва интиқоли дастгоҳҳои плёнкаи тунуки оптикӣ бо дарозии мавҷ мебошад. Ин в...Бештар -

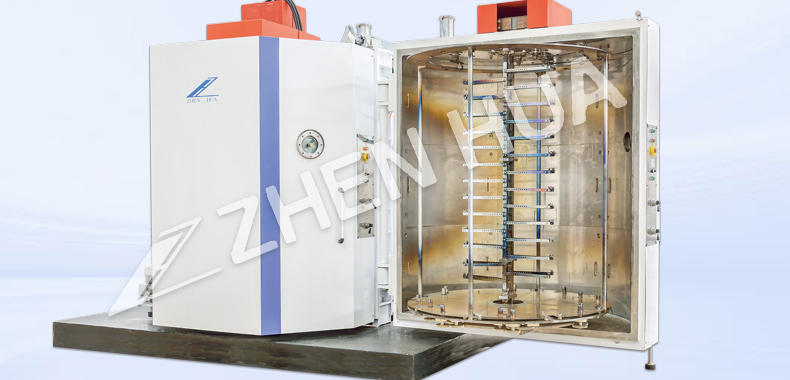

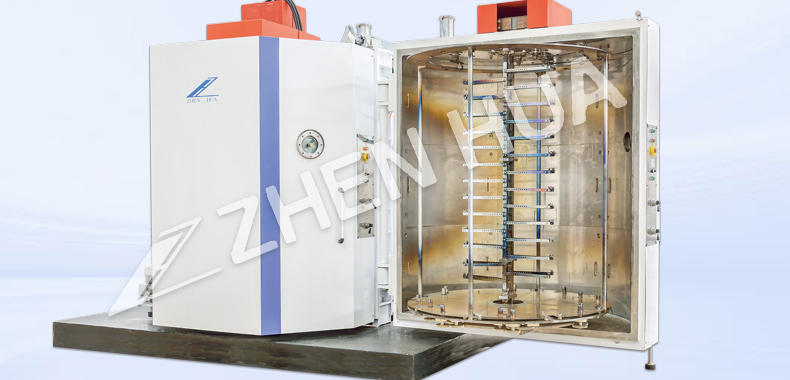

AF лоғар Филми бухоршавӣ оптикии PVD чангкашак Мошин молидани

Мошини пӯшонидани вакуумии оптикии PVD барои бухоршавии филми тунуки AF барои татбиқ кардани рӯйпӯшҳои тунук ба дастгоҳҳои мобилӣ бо истифода аз раванди таҳшини буғҳои физикӣ (PVD) тарҳрезӣ шудааст. Ин раванд эҷоди муҳити вакуумиро дар дохили камераи пӯшиш дар бар мегирад, ки дар он маводи сахт бухор карда мешаванд ва сипас ...Бештар -

Мошини истеҳсоли оинаи рӯйпӯши вакуумии нуқраи алюминий

Мошини истеҳсоли оинаи вакуумии алюминийи нуқра бо технологияи пешрафта ва муҳандисии дақиқи худ дар соҳаи истеҳсоли оина инқилоб кард. Ин мошини замонавӣ барои гузоштани қабати тунуки нуқраи алюминӣ ба рӯи шиша тарҳрезӣ шудааст, ки бо сифати баланд...Бештар -

Мошини оптикии вакуумӣ

Метализатори оптикии вакуумӣ технологияи муосирест, ки дар саноати рангкунии рӯизаминӣ инқилоб ба амал овард. Ин мошини пешрафта равандеро истифода мебарад, ки металлизатсияи оптикии вакуумӣ номида мешавад, то як қабати тунуки металлро ба субстратҳои гуногун татбиқ карда, як қабати хеле инъикоскунанда ва устуворро эҷод мекунад ...Бештар -

Ҷойгиршавии буғи кимиёвии плазма боби 2

Аксари элементҳои кимиёвиро бо роҳи муттаҳид кардани онҳо бо гурӯҳҳои химиявӣ бухор кардан мумкин аст, масалан, Si бо H реаксия карда, SiH4-ро ташкил медиҳад ва Al бо CH3 пайваст шуда, Al(CH3) -ро ташкил медиҳад. Дар ҷараёни гармии CVD, газҳои дар боло зикршуда миқдори муайяни энергияи гармиро ҳангоми гузаштан аз субстрат тафсонда, азхуд мекунанд ...Бештар -

Ҷойгиршавии буғи кимиёвии плазма боби 1

Ҷойгиршавии буғи кимиёвӣ (CVD). Тавре ки аз ном бармеояд, ин як техникаест, ки реактивҳои пешгузаштаи газро барои тавлиди филмҳои сахт тавассути реаксияҳои кимиёвии атомӣ ва байнимолекулавӣ истифода мебарад. Баръакси PVD, раванди CVD асосан дар муҳити фишори баландтар (вакууми паст) анҷом дода мешавад, ...Бештар -

Унсурҳои раванд ва механизмҳое, ки ба сифати дастгоҳҳои филми тунук таъсир мерасонанд (Қисми 2)

3. Таъсири ҳарорати субстрат Ҳарорати зеризаминӣ яке аз шартҳои муҳими афзоиши мембрана мебошад. Он ба атомҳо ё молекулаҳои мембрана энергияи иловагиро таъмин мекунад ва асосан ба сохтори мембрана, коэффисиенти агглютинатсия, коэффисиенти васеъшавӣ ва агрегатҳо таъсир мерасонад...Бештар -

Омилҳо ва механизмҳое, ки ба сифати дастгоҳҳои филми тунук таъсир мерасонанд (Қисми 1)

Истехсоли дастгоххои оптикии плёнка дар камераи вакуумй ба амал бароварда мешавад ва нашъунамои кабати плёнка процесси микроскопй мебошад. Аммо, дар айни замон, равандҳои макроскопӣ, ки мустақиман идора карда мешаванд, баъзе омилҳои макроскопӣ мебошанд, ки ба таври ғайримустақим бо ...Бештар -

Муқаддимаи таърихи рушди технологияи бухоршавӣ

Раванди гарм кардани маводи сахт дар муҳити баланди вакуумӣ барои сублиматсия ё бухоршавӣ ва гузоштани онҳо дар як субстрати мушаххас барои ба даст овардани филми тунук ҳамчун қабати бухоршавии вакуумӣ маълум аст (бо қабати бухоршавӣ номида мешавад). Таърихи тайёр кардани плёнкахои тунук тавассути бухоркунии вакуум...Бештар -

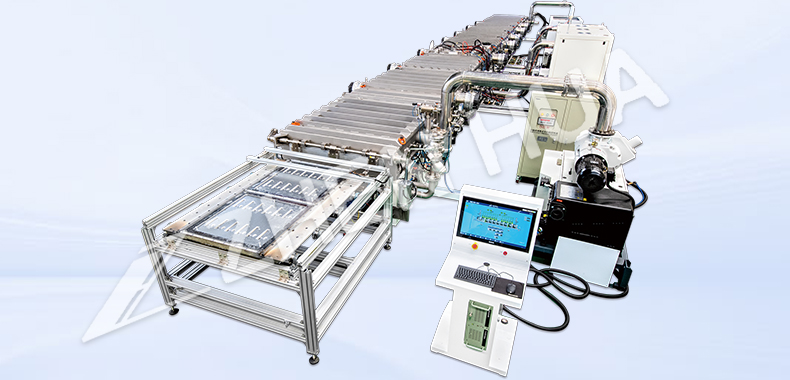

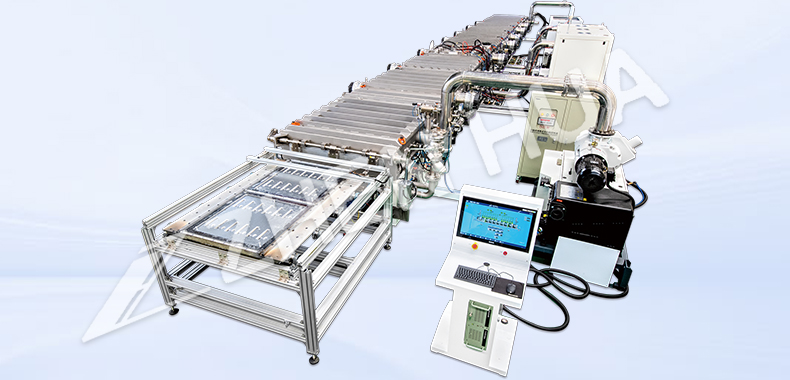

Муқаддима дар бораи молидани ITO

Оксиди қалъа (Indium Tin Oxide, ба ITO номида мешавад) як фосилаи васеъ, маводи нимноқили навъи n, бо интиқоли нури баланди намоён ва хусусиятҳои муқовимати паст ва аз ин рӯ дар ҳуҷайраҳои офтобӣ, дисплейҳои панелҳои ҳамвор, тирезаҳои электрохромӣ, ғайриорганикӣ ва органикӣ истифода мешаванд ...Бештар -

Лабораторияи вакуумӣ мошини рӯйпӯш кардани чарх

Котерҳои вакуумии лабораторӣ асбобҳои муҳим дар соҳаи таҳшин кардани филми тунук ва тағир додани сатҳи рӯизаминӣ мебошанд. Ин тачхизоти мукаммал барои дакик ва ба таври баробар ба замина гузоштани плёнкахои тунуки материалхои гуногун пешбинй шудааст. Раванд татбиқи маҳлули моеъ ё sus...Бештар -

Реҷаи ҷойгиркунии нури ионӣ ва интихоби энергияи он

Ду намуди асосии таҳшинсозии ионҳо вуҷуд доранд, ки яке гибридии динамикӣ мебошад; дигараш гибридии статикӣ мебошад. Дар собиқ ишора ба филм дар раванди афзоиши аст, ҳамеша бо як энергияи муайян ва чӯбро ҷорӣ аз бомбаборонкунии ion ва филми ҳамроҳӣ; охирин аст, пешакӣ дар сатҳи уми ...Бештар -

Технологияи ҷойгиркунии нури ион

① Технологияи ҷойгиркунии чӯби ионӣ бо пайвастшавии қавӣ байни филм ва субстрат тавсиф мешавад, қабати филм хеле қавӣ аст. Таҷрибаҳо нишон доданд, ки: бо ёрии чӯҷаи ион ҷойгиршавии адгезия нисбат ба адгезияи буғҳои гармӣ чанд маротиба зиёд шуда, ба садҳо ...Бештар