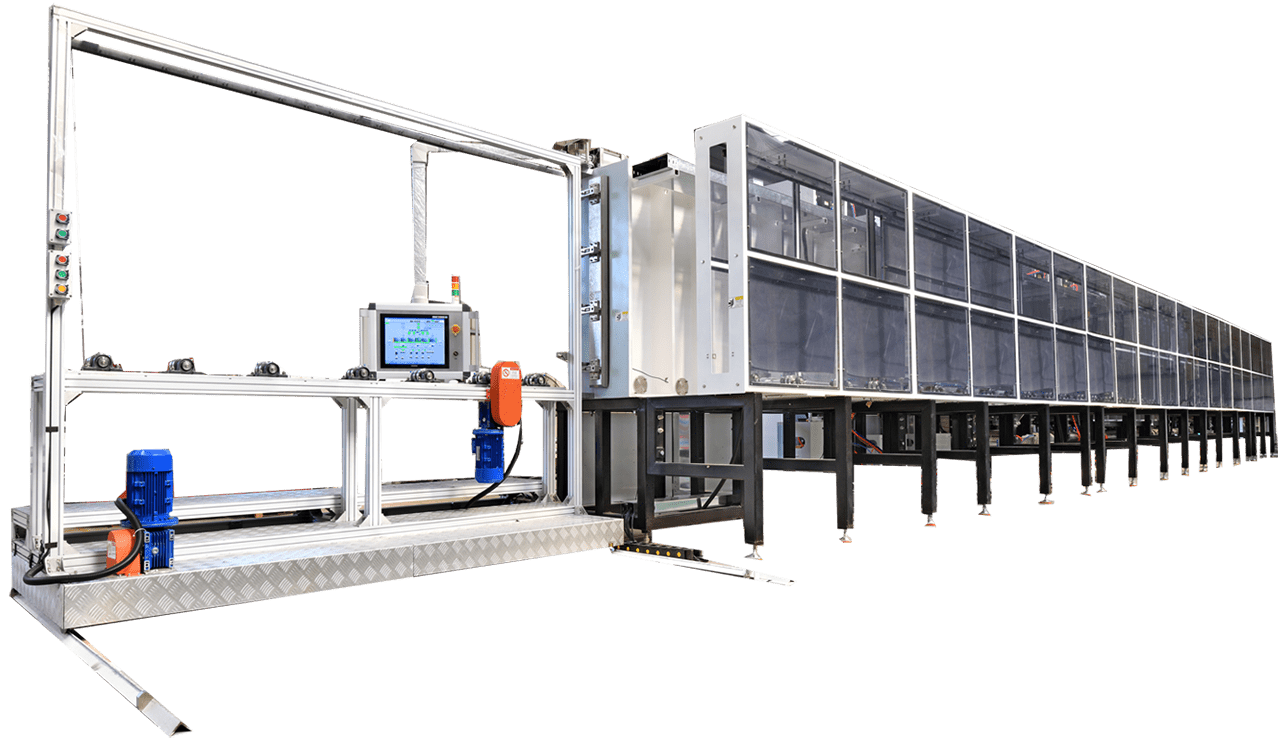

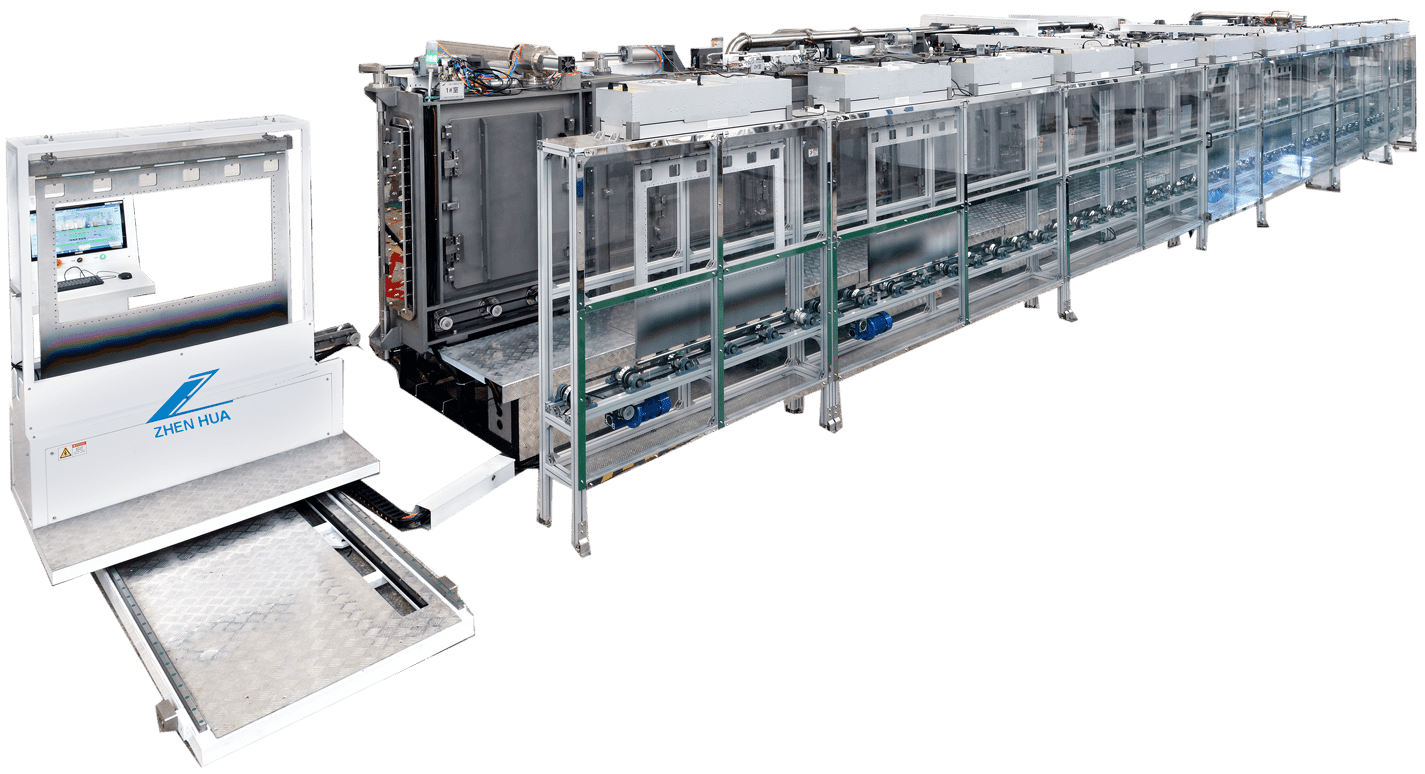

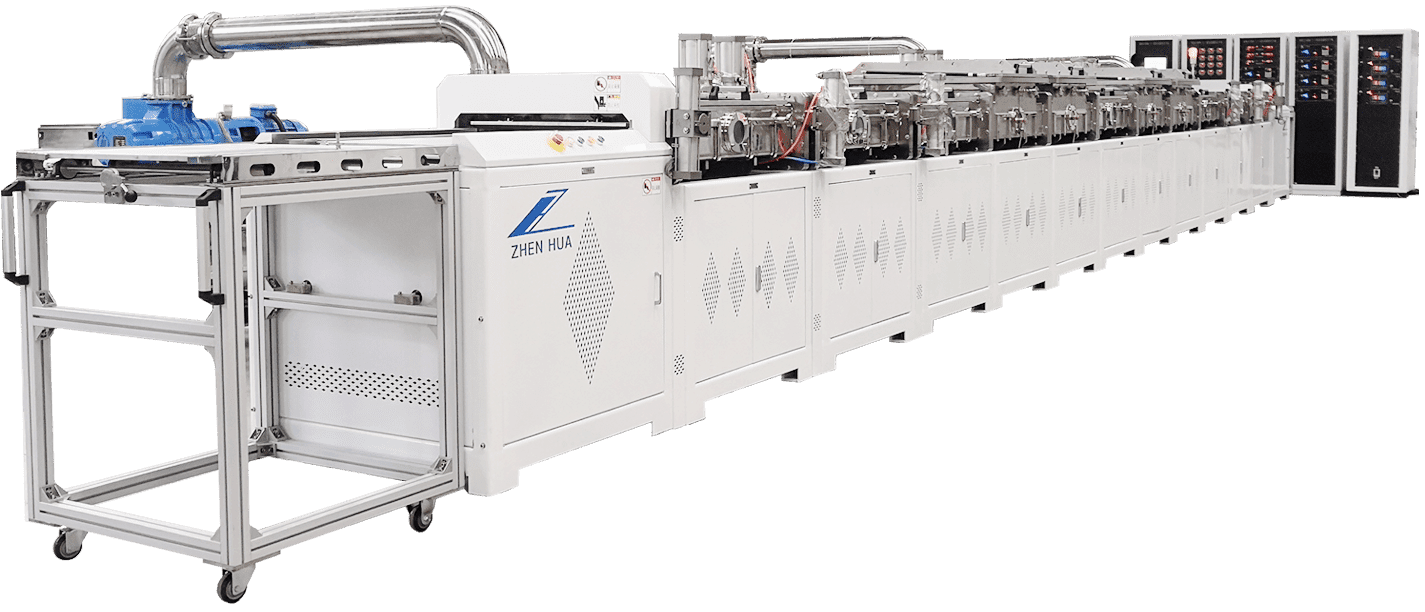

Vertical multifunctional coating production line

Get A QuotePRODUCT DESCRIPTION

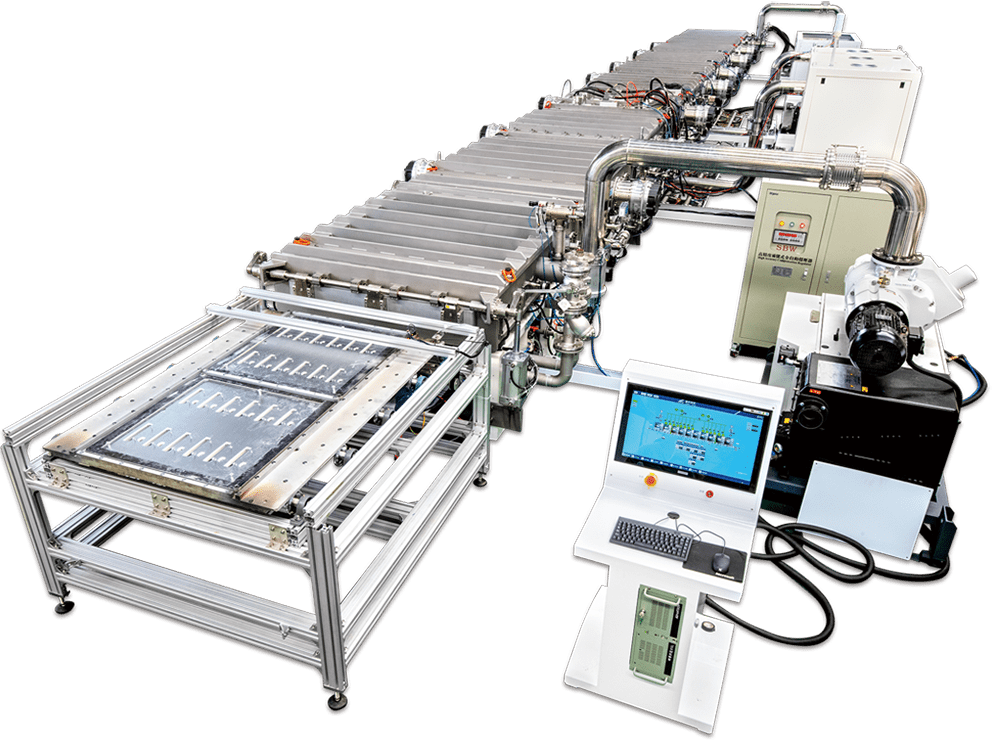

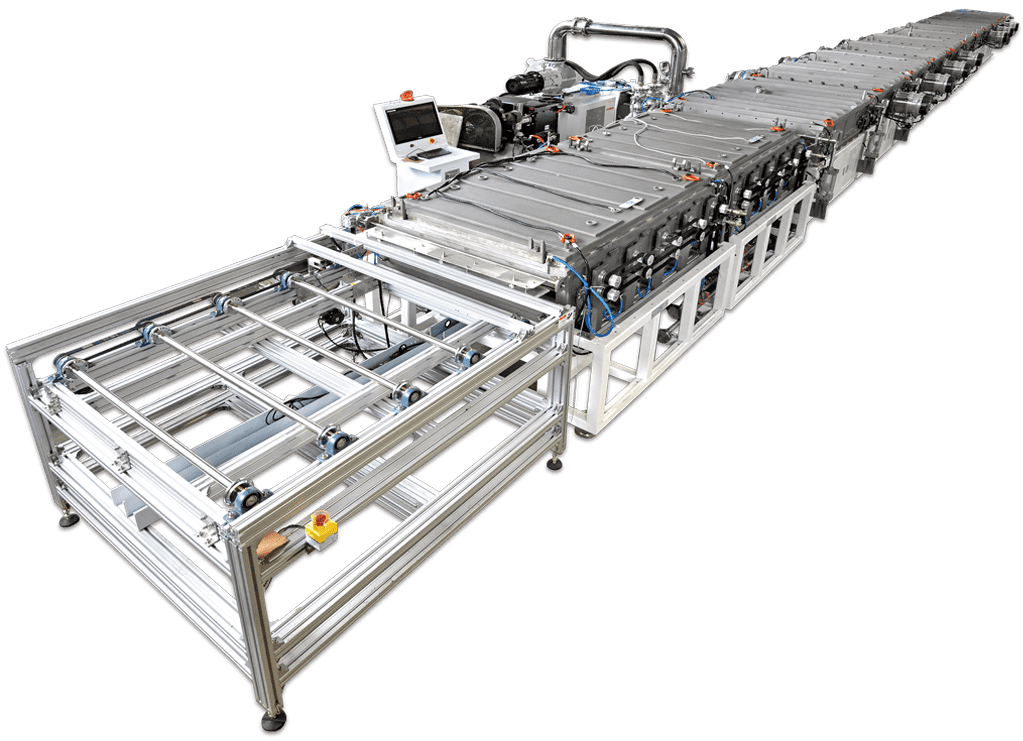

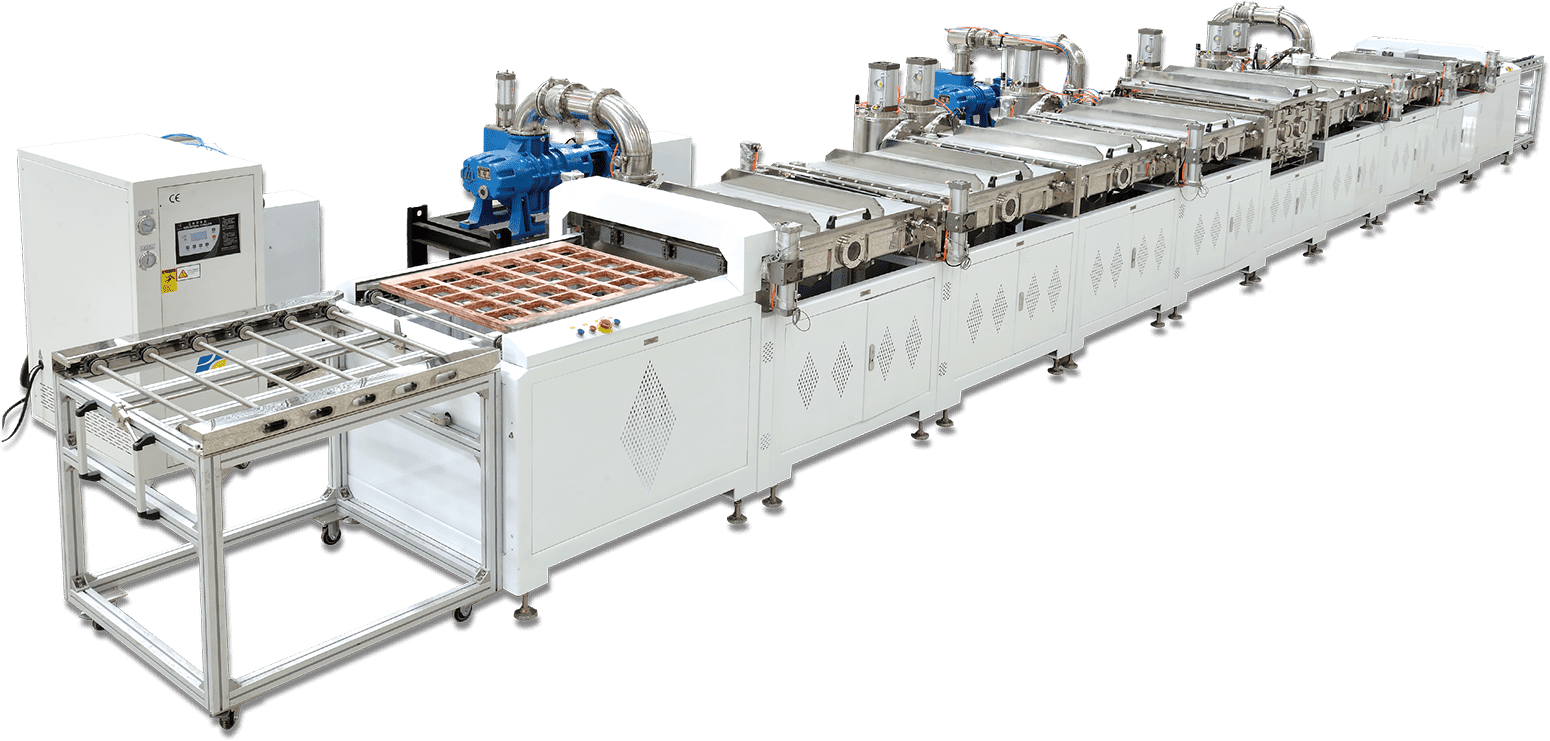

The equipment adopts vertical modular design structure and is equipped with multiple access doors to facilitate independent installation and maintenance of the cavity, assembly and future upgrading. Equipped with fully enclosed purified material rack conveying system to avoid workpiece contamination. The workpiece can be coated on one or both sides, mainly for depositing optical color film or metal film.

The coating room of the equipment maintains a high vacuum state for a long time, with less impurity gas, high purity of the coating and good refractive index. The fully automatic speedflo closed-loop control system is configured to improve the film deposition rate. The process parameters can be traced, and the production process can be monitored in the whole process to facilitate the tracking of production defects. The equipment has a high degree of automation. It can be used together with the manipulator to connect the front and rear processes and reduce the labor cost.

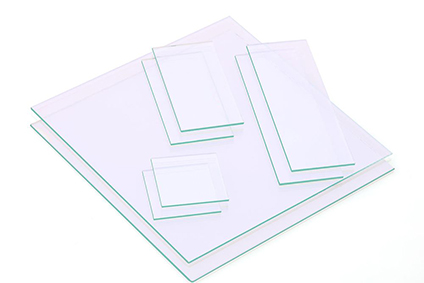

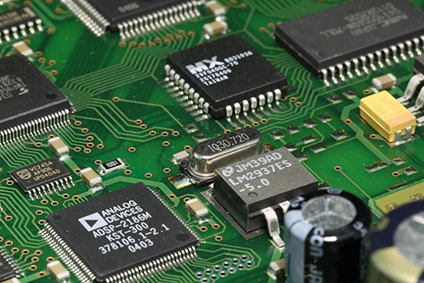

The coating production line can be used to coat Nb2O5, SiO2, TiO2, in, Cu, Cr, Ti, SUS, Ag and other oxides as well as simple metal materials. It is mainly used in the optical color film process of superposition of metal and optical materials. It is suitable for flat products made of glass, PC, PET and other materials. It has been widely used in PET film / composite plate, glass cover plate, display screen and other products.