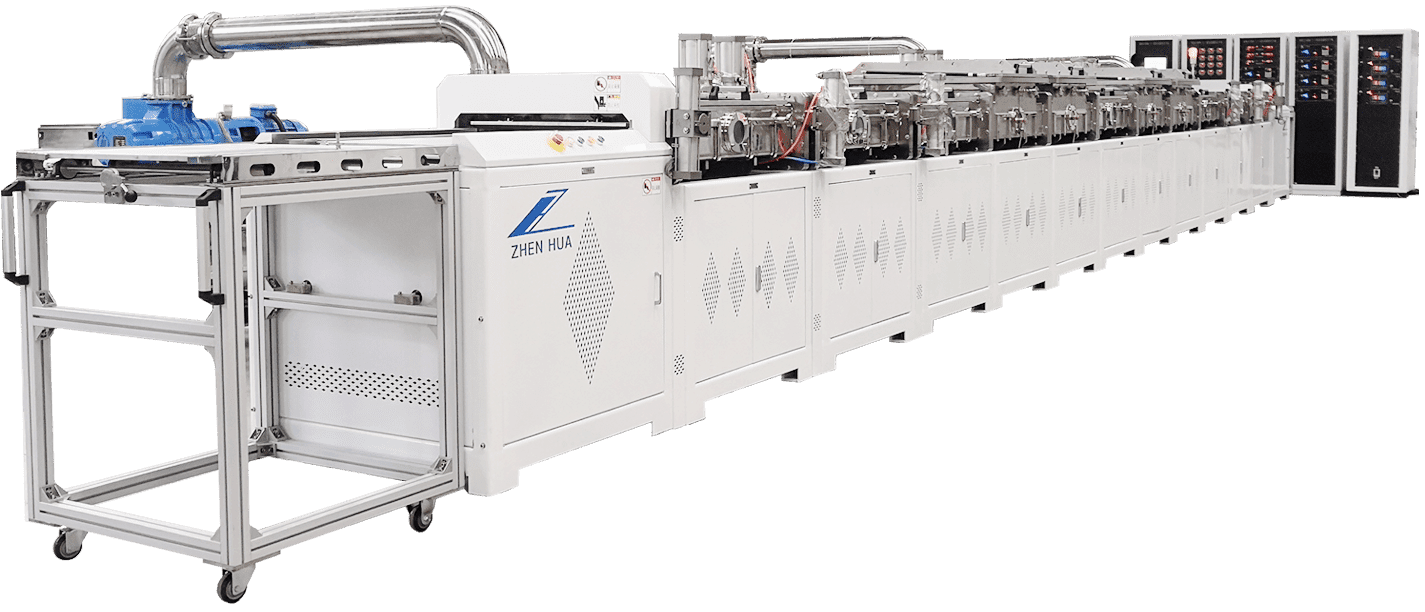

Wholesale Discount Cvd Coating Equipment - Hot filament CVD equipment – Zhenhua

Get A QuotePRODUCT DESCRIPTION

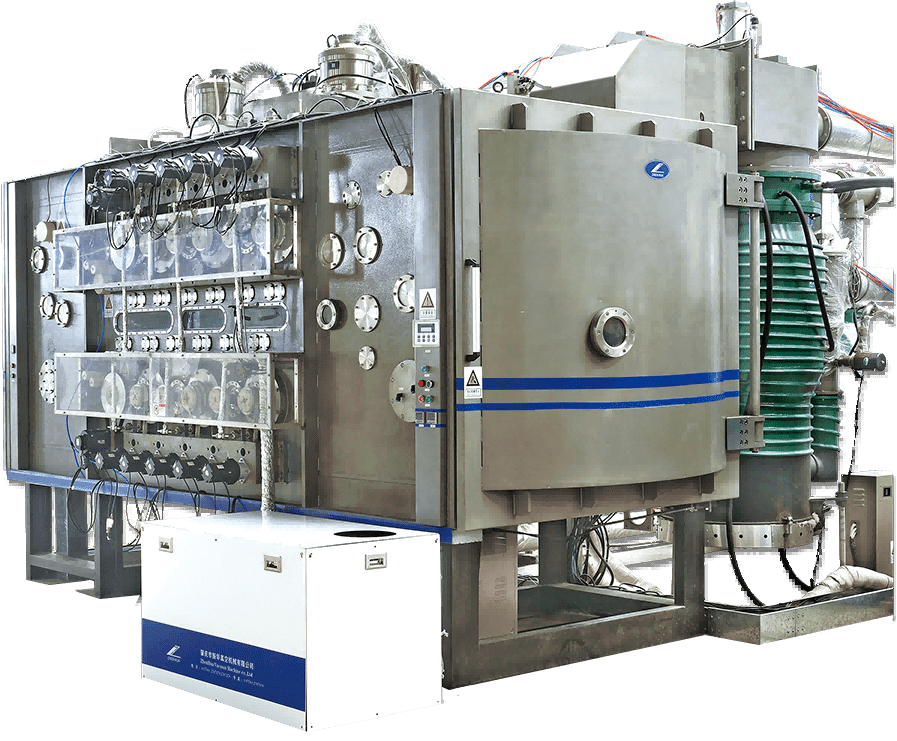

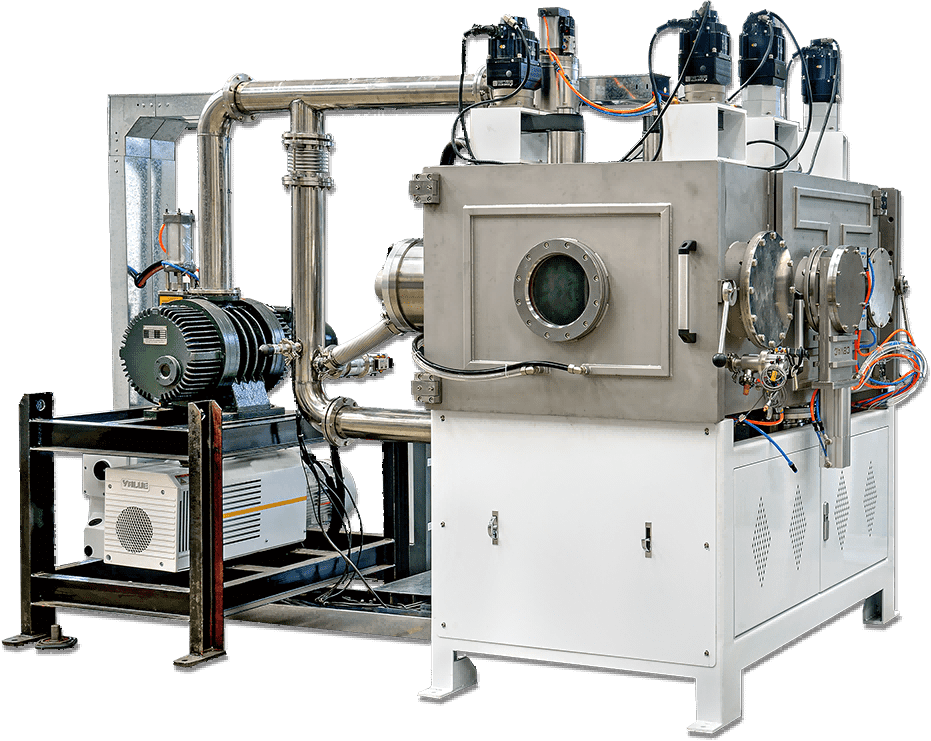

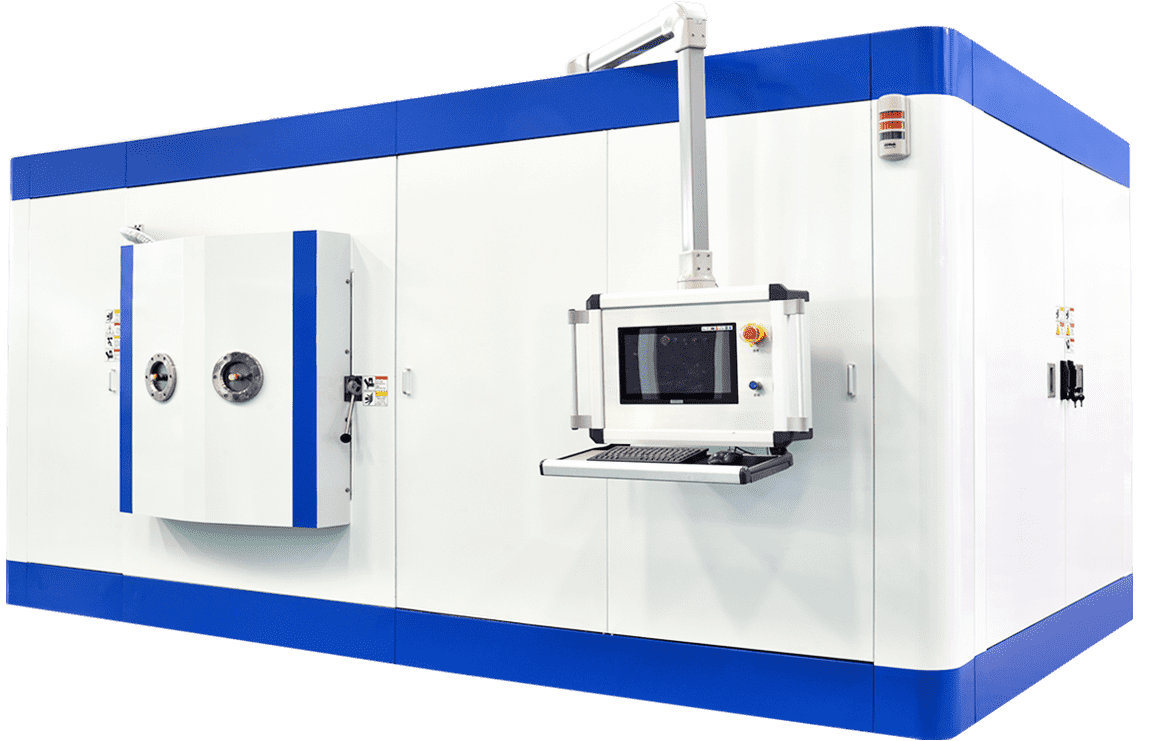

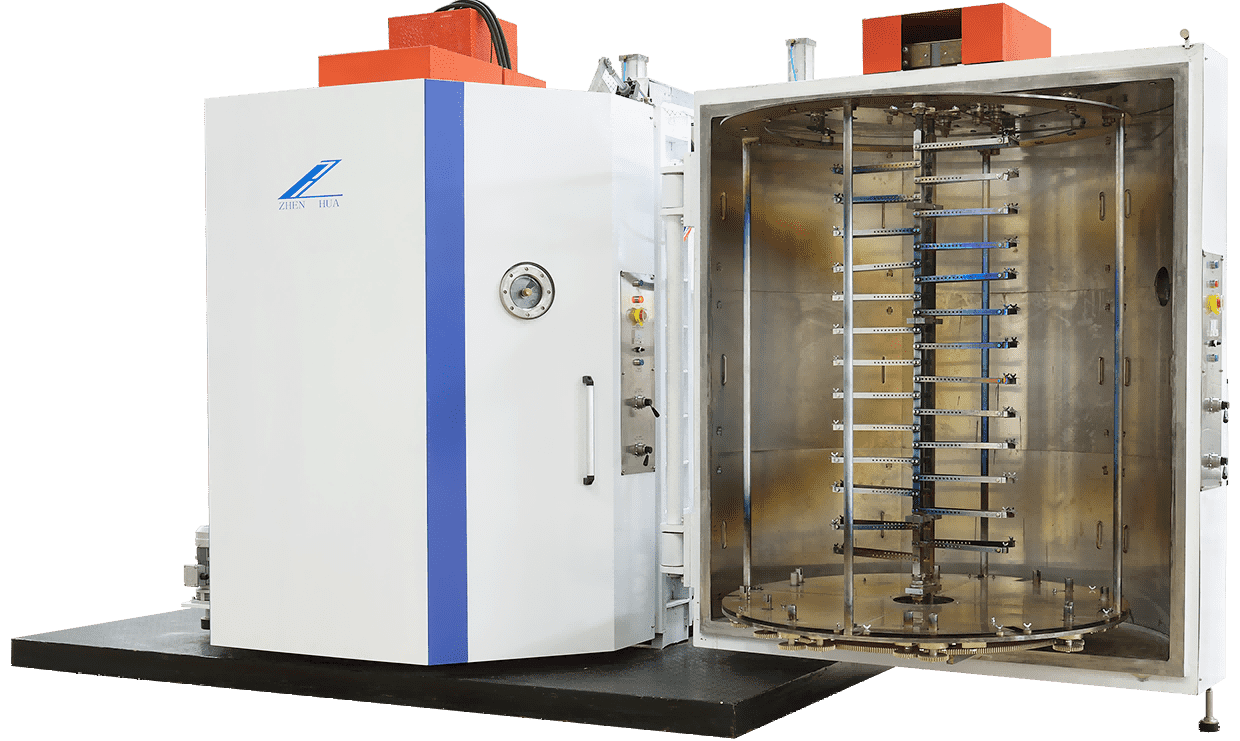

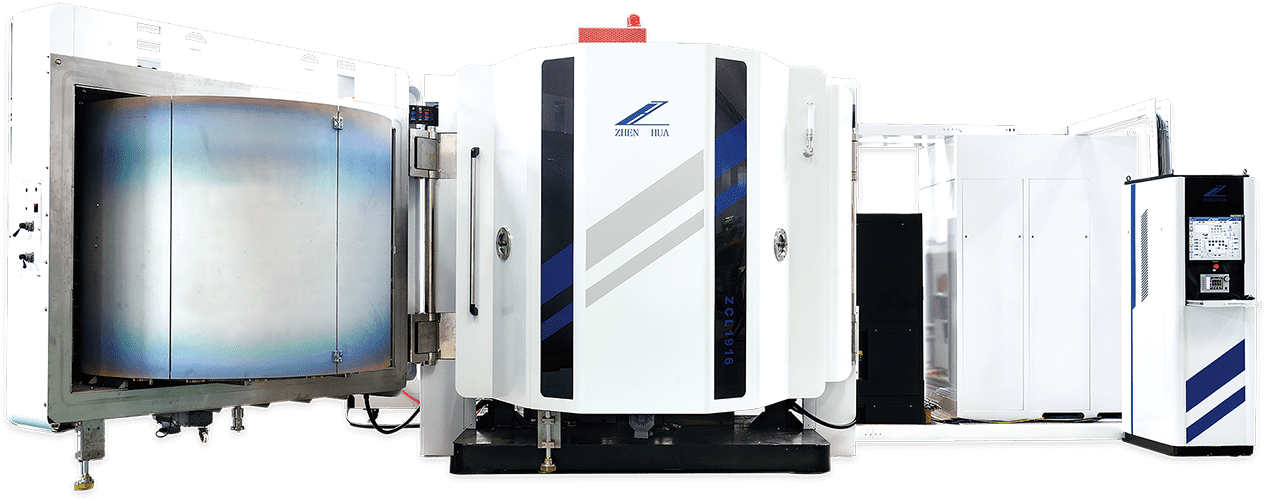

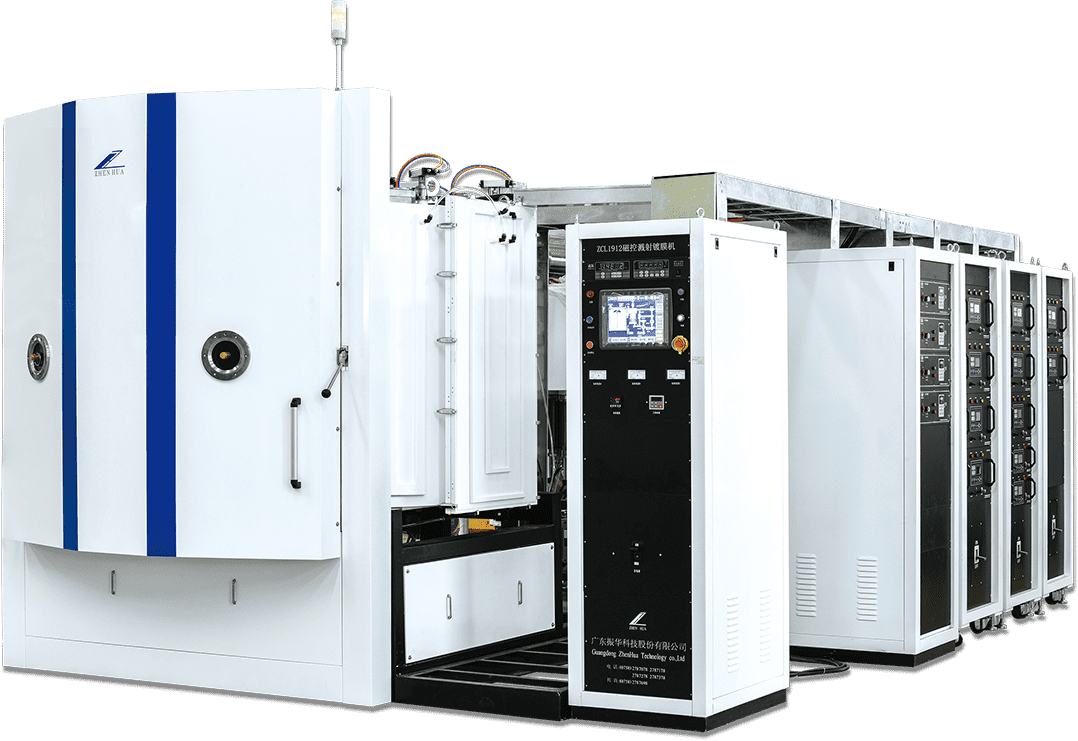

The vacuum coating chamber of the chemical vapor deposition equipment adopts an independent double-layer water-cooling structure, which is efficient and uniform in cooling, and has a safe and stable structure. The equipment is designed with double doors, multiple observation windows and multiple expansion interfaces, which is convenient for external connection of auxiliary peripherals such as infrared temperature measurement, spectral analysis, video monitoring and thermocouple. The advanced design concept makes the daily overhaul and maintenance, configuration change and upgrade of the equipment easy and simple, and effectively reduces the use and upgrade costs.

Equipment features:

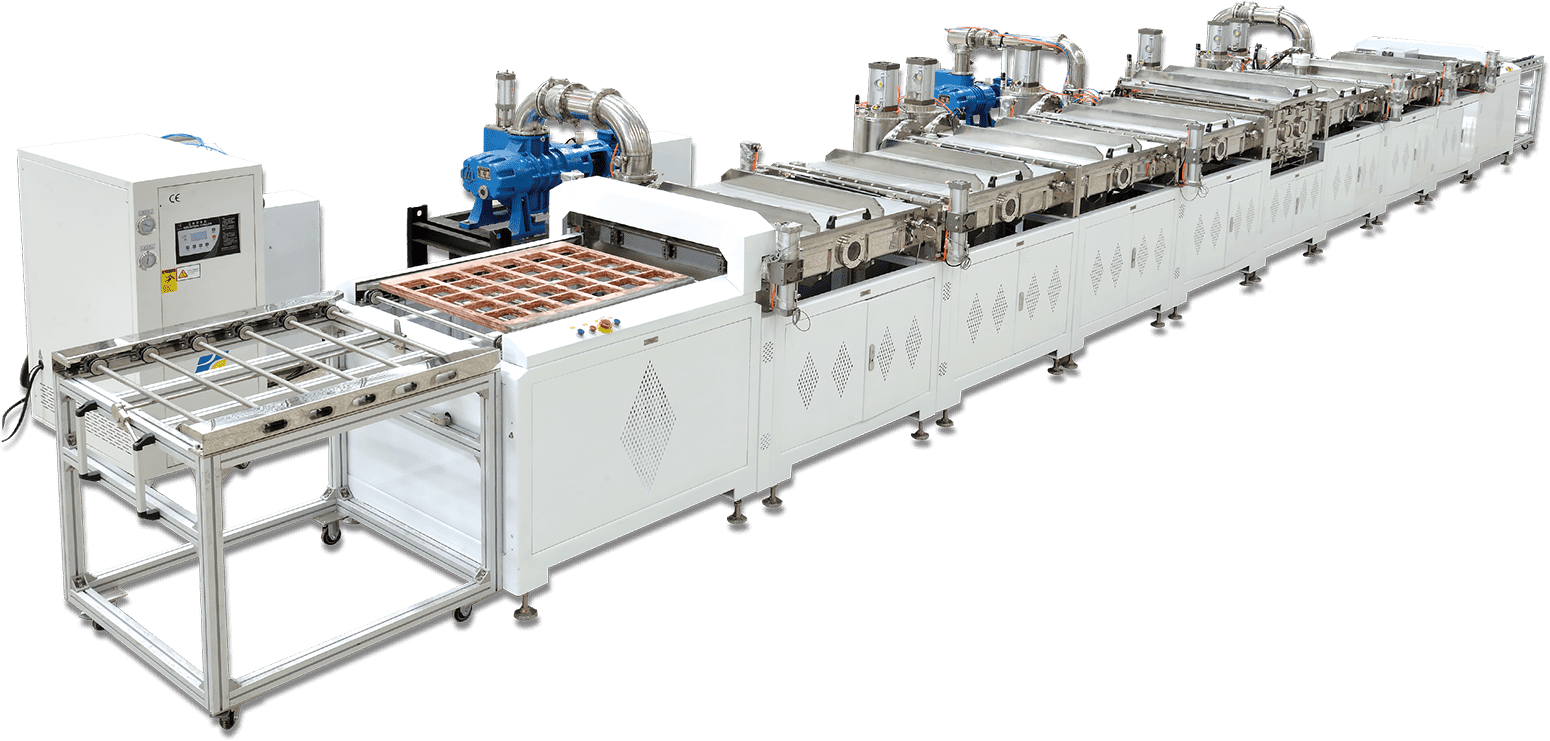

1.The inflation components of the equipment mainly include mass flow meter, solenoid valve and gas mixing tank, which ensure the accurate control of process gas flow, uniform mixing and safe isolation of different gases, and can select gas system components for the use of liquid gas source, facilitate the personalized selection of a wide range of liquid carbon sources, and the safe use of synthetic conductive diamond and electrode liquid boron sources.

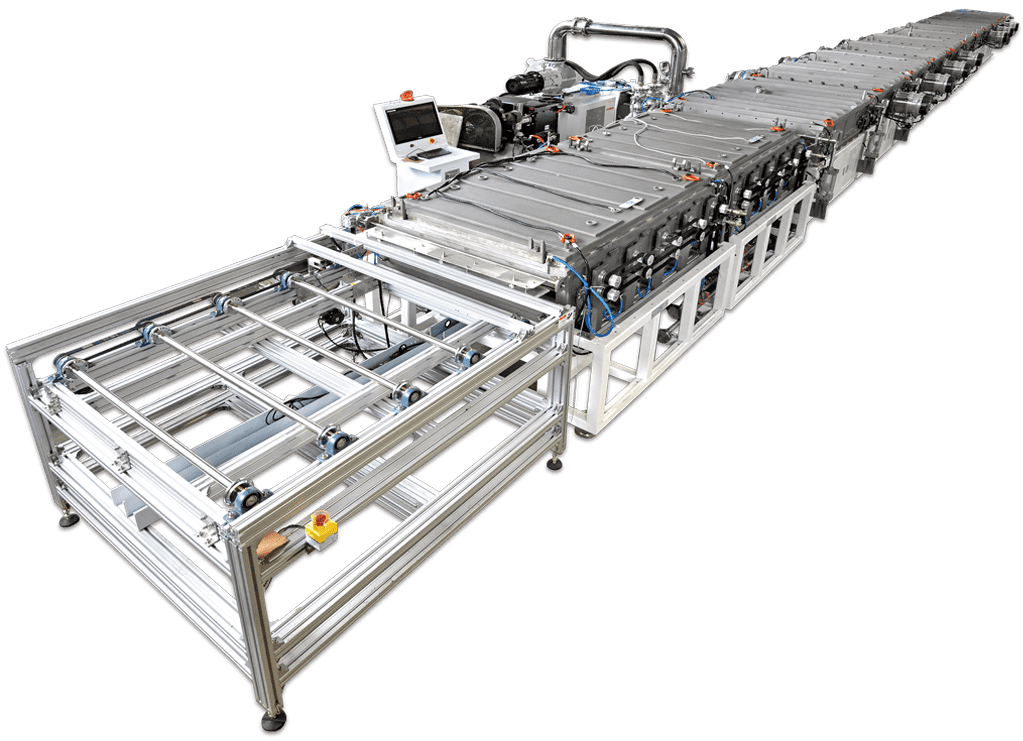

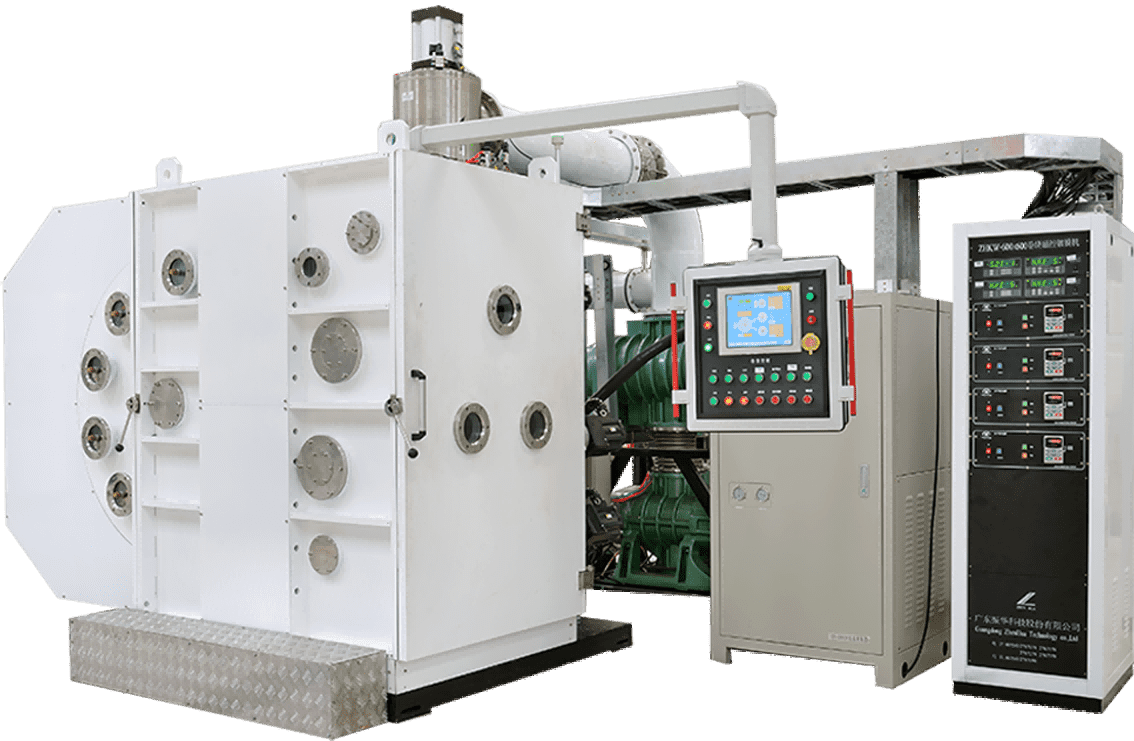

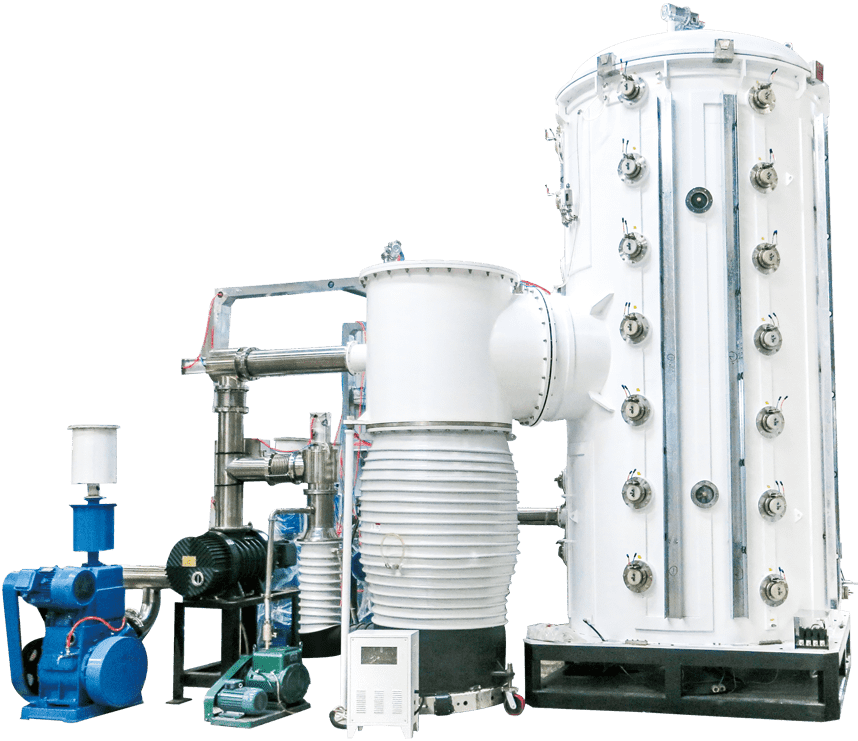

2.The air extraction assembly is equipped with a silent and efficient rotary vane vacuum pump and a turbo molecular pump system that can quickly meet the high vacuum background environment. The composite vacuum gauge with resistance gauge and ionization gauge is used for vacuum measurement, as well as the capacitive film gauge system which can measure the pressure of different process gases in a wide range. The deposition pressure is fully automatic controlled by high-precision proportional control valve.

3.The cooling water component is equipped with multi-channel water pressure, flow, temperature measurement and software automatic monitoring. Different cooling components are independent of each other, which is convenient for rapid fault diagnosis. All branches have independent valve switches, which is safe and efficient.

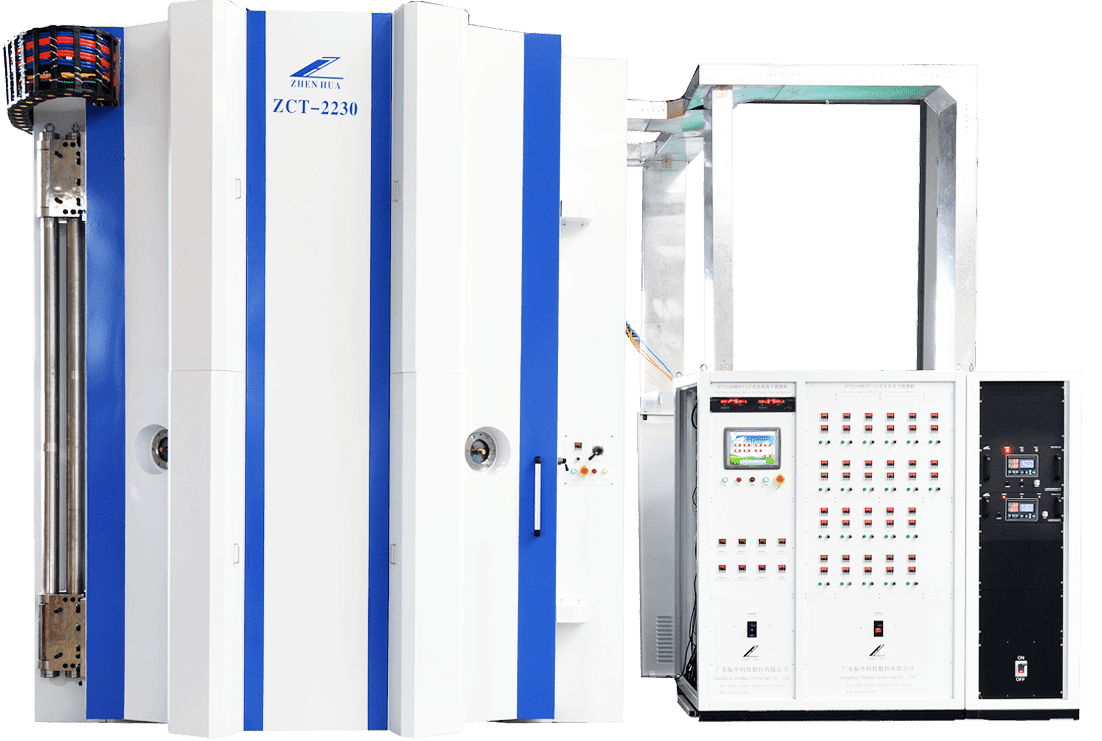

4.The electrical control components adopt large-size man-machine interface LCD screen and cooperate with PLC full-automatic control to facilitate the editing and import of process formula. The graphical curve visually displays the changes and values of various parameters, and the equipment and process parameters are automatically recorded and archived to facilitate problem tracing and data statistical analysis.

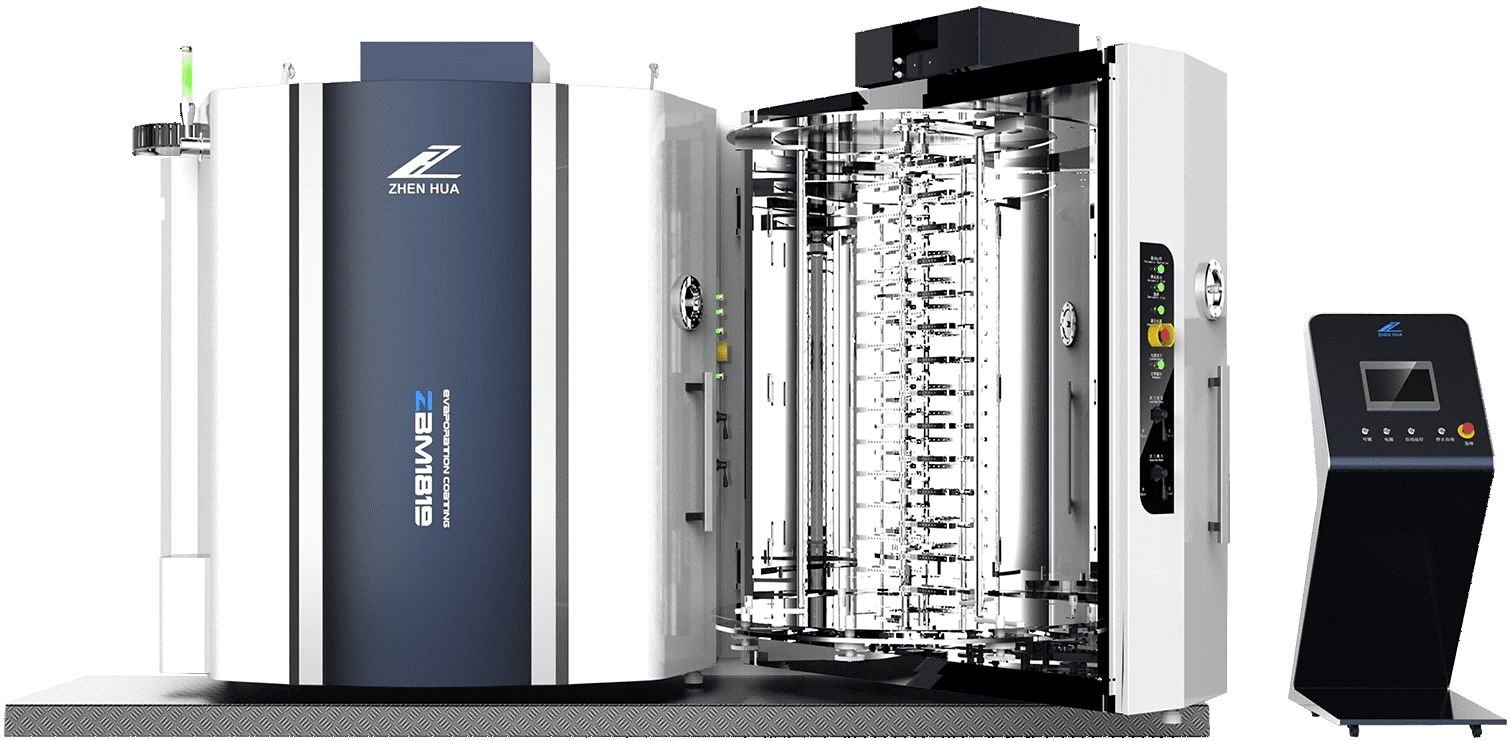

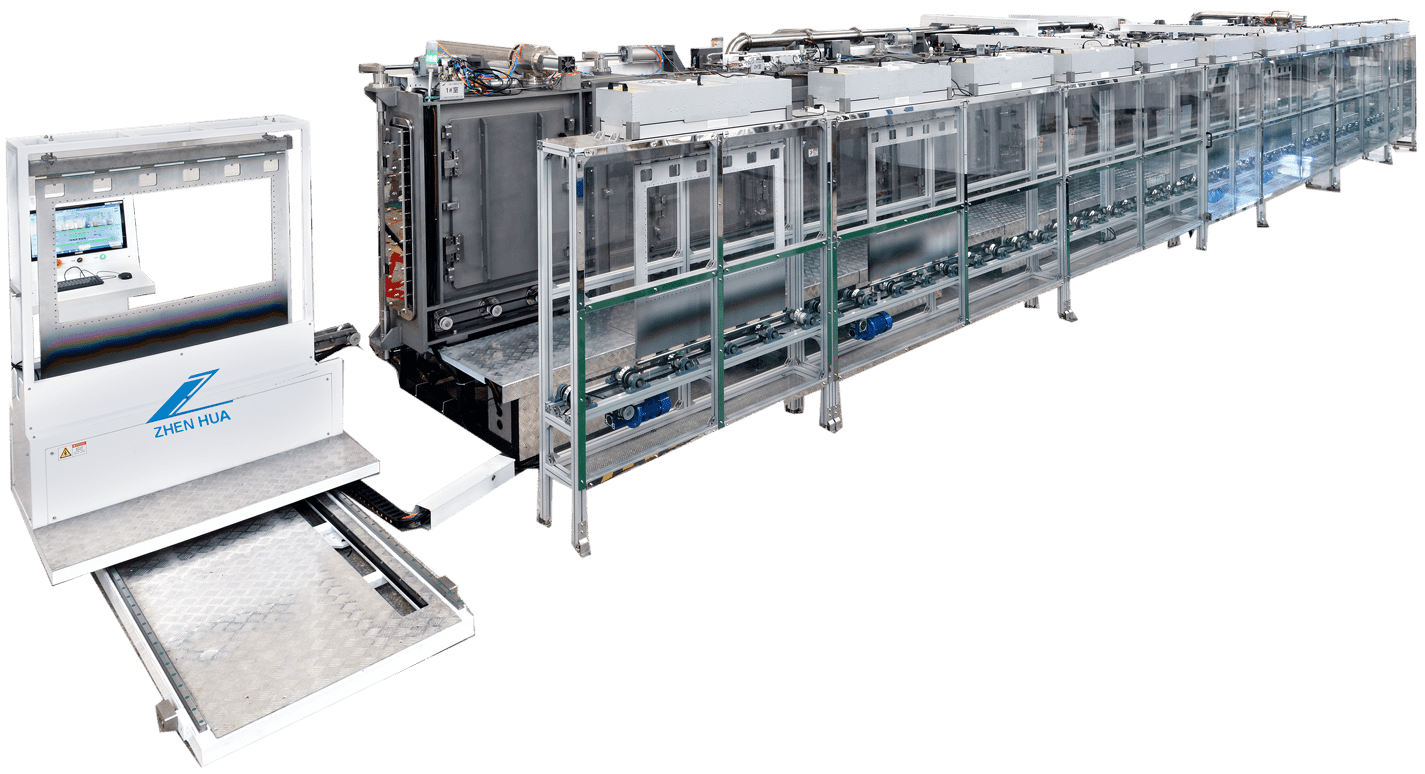

5.The workpiece rack is equipped with a servo motor to control the lifting and lowering of the substrate table. The graphite or red copper substrate table can be selected. The temperature is measured by a thermocouple.

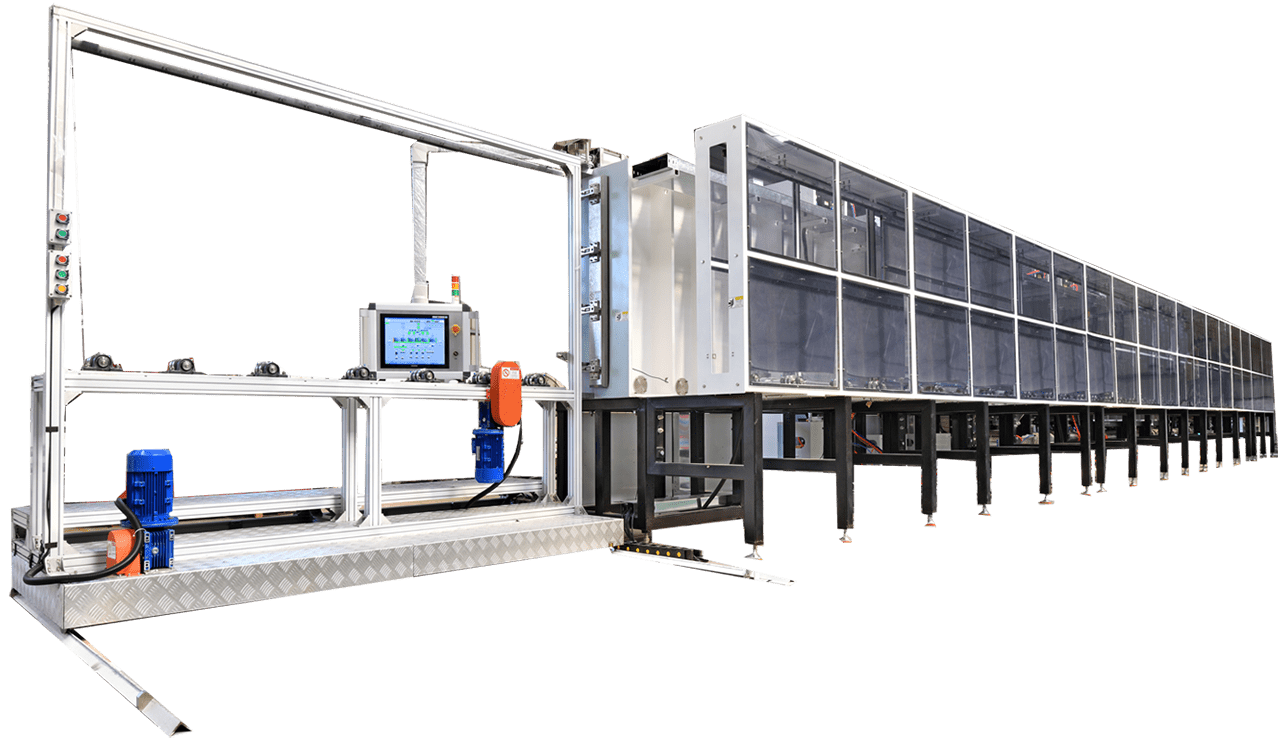

6.The rack components can be designed as a whole or separately according to customer requirements to meet the special handling requirements of customers.

7.The sealing plate components are beautiful and elegant. The sealing plates in different functional module areas of the equipment can be quickly disassembled or opened and closed independently, which is very convenient to use.

Hot filament CVD equipment is suitable for depositing diamond materials, including thin film coating, self-supporting thick film, microcrystalline and nanocrystalline diamond, conductive diamond, etc. It is mainly used for wear-resistant protective coating of cemented carbide cutting tools, semiconductor materials such as silicon and silicon carbide, heat dissipation coating of devices, boron doped conductive diamond electrode, ozone disinfection of electrolytic water or sewage treatment.

| Optional models | inner chamber size |

| HFCVD0606 | φ600*H600(mm) |