Olona phawu luphambili lwendlela yokufunxa ivacuum yokufaka iifilimu lizinga eliphezulu lokubeka. Inqaku eliphambili lendlela yokutshiza luluhlu olubanzi lwezixhobo zefilimu ezifumanekayo kunye nokufana okuhle komgangatho wefilimu, kodwa izinga lokubeka liphantsi. Ion yokwaleka yindlela edibanisa ezi nkqubo zimbini.

Umgaqo wokugquma i-ion kunye neemeko zokwenza ifilimu

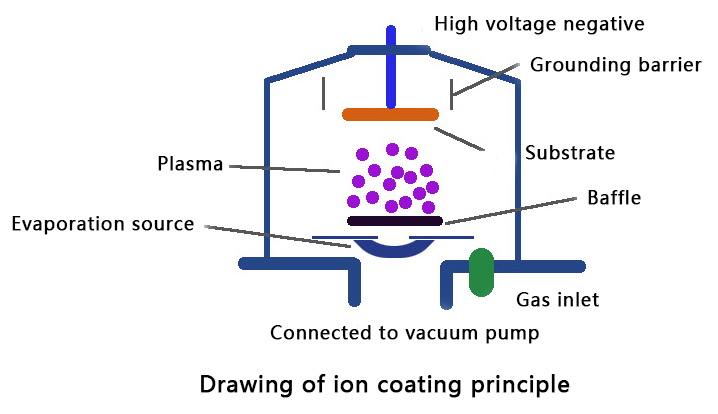

Umgaqo wokusebenza we-ion coating uboniswe kwiPic. Igumbi le-vacuum liphonswe kuxinzelelo olungaphantsi kwe-10-4 Pa, kwaye emva koko lizaliswe ngegesi ye-inert (umzekelo, i-argon) kuxinzelelo lwe-0.1 ~ 1 Pa. Emva kokuba i-voltage ye-DC engalunganga ukuya kwi-5 kV isetyenziswe kwi-substrate, i-low pressure gas glow discharge zone yeplasma isungulwa phakathi kwe-substrate kunye ne-crucible. I-ioni yegesi ye-inert ikhawuleza yintsimi yombane kwaye ibhobhoze indawo ye-substrate, ngaloo ndlela ihlambulula umphezulu womsebenzi. Emva kokuba le nkqubo yokucoca igqityiwe, inkqubo yokugubungela iqala ngokunyuka kwe-vaporization yezinto eziza kufakwa kwi-crucible. Amasuntswana omphunga omoya angena kwindawo yeplasma kwaye angqubane kunye ne-ioni edibeneyo ye-inert edibeneyo kunye ne-electron, kwaye amanye amasuntswana omphunga adityanisiwe kwaye abhobhoze i-workpiece kunye ne-coating surface phantsi kokukhawuleza kwendawo yombane. Kwinkqubo ye-ion plating, akukho kufakwa kuphela kodwa kunye nokutshiza kwee-ion ezilungileyo kwi-substrate, ngoko ke ifilimu encinci inokwakheka kuphela xa i-deposition effect inkulu kune-sputtering effect.

Inkqubo yokugquma i-ion, apho i-substrate isoloko ibhobhozwa nge-ion ene-eneji ephezulu, icocekile kakhulu kwaye ineenzuzo ezininzi xa kuthelekiswa ne-sputtering kunye ne-evaporation coating.

(1)Uncamathelo olomeleleyo, umaleko wokugquma awuxobuki lula.

(a)Kwinkqubo yokugquma i-ion, inani elikhulu lamandla aphezulu avela kukukhutshwa okukhanyayo asetyenziselwa ukuvelisa i-cathodic sputtering effect ebusweni be-substrate, ukuhlamba kunye nokucoca igesi kunye ne-oyile adsorbed phezu kwe-substrate ukucoca i-substrate surface kuze kube yilapho yonke inkqubo yokugqoka igqityiwe.

(b) Kwinqanaba lokuqala lokugquma, ukutshiza kunye nokubekwa ndawonye, okunokuthi kwenze umaleko wenguqu yamacandelo kwindawo yojongano lwesiseko sefilimu okanye umxube wezinto zefilimu kunye nesiseko, esibizwa ngokuba "yi-pseudo-diffusion layer", enokuphucula ngokufanelekileyo ukusebenza kwefilimu.

(2)Iindawo ezintle zokusonga. Esinye isizathu kukuba ii-athomu zezinto zokugquma zi-ionized phantsi koxinzelelo oluphezulu kwaye zingqubuzane neemolekyuli zegesi ngamaxesha amaninzi ngexesha lenkqubo yokufikelela kwi-substrate, ukuze i-ion eziphathekayo zisasazeke malunga ne-substrate. Ukongezelela, i-athomu yezinto zokugquma i-ionized zifakwe kumphezulu we-substrate phantsi kwesenzo sombane wombane, ngoko ke yonke i-substrate ifakwe kwifilimu encinci, kodwa i-evaporation coating ayikwazi ukufezekisa le mpembelelo.

(3) Umgangatho ophezulu we-coating ngenxa yokutshiza kwee-condensates ezibangelwa ukuqhuma rhoqo kwe-bombardment yefilimu egciniweyo kunye ne-ion ekhangayo, ephucula ukuxinana komgca wokugquma.

(4)Ukhetho olubanzi lwezinto zokugquma kunye ne-substrates inokugqunywa kwizinto zetsimbi okanye ezingezizo ezentsimbi.

(5) Xa kuthelekiswa ne-chemical vapor deposition (CVD), inobushushu obuphantsi be-substrate, ngokuqhelekileyo ngaphantsi kwe-500 ° C, kodwa amandla ayo okubambelela afaniswa ngokupheleleyo neefilimu zokubeka umphunga wekhemikhali.

6

Ukungalungi kokwaleka kwe-ion zezi: ubukhulu befilimu abukwazi ukulawulwa ngokuchanekileyo; ukugxininiswa kweziphene kuphezulu xa kufuneka i-coating coating; kunye neegesi ziya kungena kumphezulu ngexesha lokugquma, okuya kutshintsha iimpawu zomhlaba. Kwezinye iimeko, i-cavities kunye ne-nuclei (ngaphantsi kwe-1 nm) nazo zenziwe.

Ngokubhekiselele kwireyithi yokubeka, ukugquma kwe-ion kuthelekiseka nendlela yokuphuma komphunga. Ngokubhekiselele kumgangatho wefilimu, iifilimu eziveliswa yi-ion coating zisondele okanye zingcono kunezo zilungiswe ngokutshiza.

Ixesha lokuposa: Nov-08-2022