INCAZELO YOMKHIQIZO

Imishini isebenzisa ubuchwepheshe bokuhlanganisa i-cathode arc ion futhi ifakwe uhlelo oluthuthukisiwe lwe-IET etching. Ngemuva kokwelashwa, umkhiqizo ungafaka ngokuqondile i-coating eqinile ngaphandle kwesendlalelo soguquko. Ngaso leso sikhathi, ubuchwepheshe be-arc bendabuko buthuthukiselwa kukazibuthe ongunaphakade kanye nobuchwepheshe bokuskena ikhoyili kagesi. Lobu buchwepheshe bungathuthukisa ngempumelelo amandla e-ion, buthuthukise izinga le-ionization nezinga lokusebenzisa okuqondiwe, busheshise isivinini sokunyakaza kwendawo ye-arc, luvimbele ngempumelelo ukukhiqizwa kwamaconsi, lwehlise ukushuba kwefilimu, futhi lwehlise i-coefficient yokungqubuzana kwefilimu. Ikakhulukazi ngethagethi ye-aluminium, ingathuthukisa kakhulu impilo yesevisi ye-workpiece. Ifakwe i-3D engasindi yakamuva, ukufana nokuzinza kungcono.

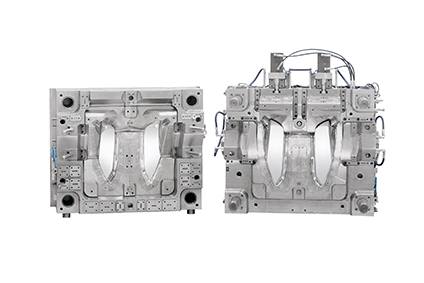

Imishini ingambozwa nge-AlTiN / AlCrN / TiCrAlN / TiAlSiN / CrN nezinye izigqoko eziqinile ezisezingeni eliphezulu, ezisetshenziswe kabanzi ekubunjeni, amathuluzi okusika, izibhakela, izingxenye zezimoto, i-plunger neminye imikhiqizo.

Izici zobuchwepheshe

1. I-plasma ethuthukisiwe, ukuskena okujikelezayo kwe-electromagnetic okuqinile okunyakazayo kwe-cathode ebandayo, i-diffraction eqinile, ifilimu eliminyene.

2. ibanga elide lokufafaza, amandla aphezulu kanye nokunamathela okuhle.

3. Ibanga le-anode ehlabayo ye-arc lingalungiswa ngaphandle kokuvala shaqa ukuze lilungiswe.

4. Isakhiwo sethrekhi yenzuzo sikulungele ukufaka esikhundleni nokugcina i-cathode ebandayo.

5. indawo ye-arc spot iyalawuleka, futhi izindlela ezihlukene zikakazibuthe zingalungiswa ngokuya ngezinto ezahlukene.

Izibonelo zezakhiwo zokumboza

| Izembatho | Ubukhulu (um) | Ukuqina (HV) | Izinga lokushisa eliphezulu(℃) | Umbala | Isicelo |

| Ta-C | 1-2.5 | 4000-6000 | 400 | Mnyama | I-graphite, i-carbon fiber, izinhlanganisela, i-aluminium ne-aluminium alloys |

| TiSiN | 1-3 | 3500 | 900 | Ibhulonzi | I-55-60HRC yokusika insimbi engagqwali, ukuqedwa okuhle |

| I-AlTiN-C | 1-3 | 2800-3300 | 1100 | Okumpunga okuluhlaza | Ubulukhuni obuphansi bokusika insimbi engagqwali, ukwakha isikhunta, isikhunta sokunyathela |

| I-CrAlN | 1-3 | 3050 | 1100 | Okumpunga | Isikhunta esinzima sokusika nokunyathela |

| I-CrAlSiN | 1-3 | 3520 | 1100 | Okumpunga | I-55-60HRC yokusika insimbi engagqwali, ukuqedwa okuhle, ukusika okomile |

Amamodeli ongawakhetha

| I-HDA0806 | I-HDA1112 |

| φ850*H600(mm) | φ1100*H1200(mm) |