Isimiso se-vacuum evaporation coating

1, Imishini kanye nenqubo engokomzimba ye-vacuum evaporation coating

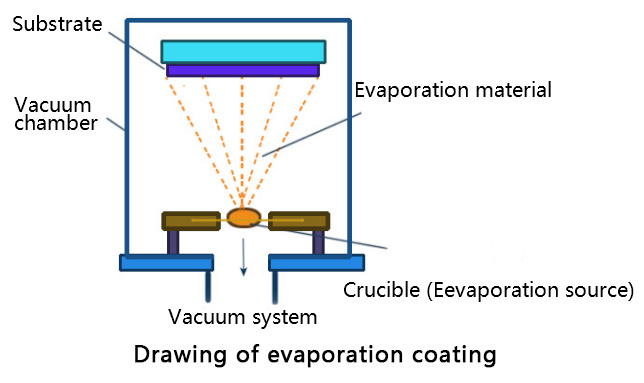

Imishini yokufaka umhwamuko wevacuum ikakhulukazi yakhiwe igumbi le-vacuum kanye nesistimu yokukhipha. Ngaphakathi kwegumbi le-vacuum, kunomthombo wokuhwamuka (okungukuthi i-heater ehwamukayo), i-substrate kanye nohlaka lwe-substrate, i-substrate heater, i-exhaust system, njll.

Izinto zokumboza zifakwa emthonjeni wokuhwamuka wegumbi le-vacuum, futhi ngaphansi kwezimo eziphezulu ze-vacuum, zishiswa umthombo wokuhwamuka ukuze zihwamuke. Lapho isilinganiso samahhala sezinhlayiya zomhwamuko sikhulu kunosayizi womugqa wegumbi le-vacuum, ngemva kokuba ama-athomu nama-molecule omusi wefilimu ephunyukile ebusweni bomthombo wokuhwamuka, awavamisile ukuthi avinjwe ukungqubuzana kwamanye ama-athomu noma ama-athomu, futhi afinyelele ngokuqondile ebusweni be-substrate ezombozwa. Ngenxa yokushisa okuphansi kwe-substrate, izinhlayiya ze-vapor zefilimu zibopha phezu kwayo futhi zenze ifilimu.

Ukuze kuthuthukiswe ukunamathela kwama-molecule e-evaporation kanye ne-substrate, i-substrate ingenziwa isebenze ngokushisa okufanele noma ukuhlanza i-ion. I-vacuum evaporation coating idlula kulezi zinqubo zomzimba ezilandelayo ukusuka ekuhwamukeni kwezinto ezibonakalayo, ukuthuthwa kuye ekufakweni efilimini.

(1)Isebenzisa izindlela ezihlukahlukene zokuguqula ezinye izinhlobo zamandla zibe amandla ashisayo, ifilimu iyashiswa ukuze ihwamuke noma ishintshe ibe yizinhlayiya zegesi (ama-athomu, ama-molecule noma amaqoqo e-athomu) ngenani elithile lamandla (0.1 kuya ku-0.3 eV).

(2)Izinhlayiya zegesi zisuka ebusweni befilimu futhi zithuthelwe phezulu kwe-substrate ngesivinini esithile sokunyakaza, ngokuyisisekelo ngaphandle kokungqubuzana, ngomugqa oqondile.

(3)Izinhlayiya zegesi ezifika phezu kwe-substrate coalesce ne-nucleate, bese zikhula zibe ifilimu yesigaba esiqinile.

(4)Ukuhlelwa kabusha noma ukuhlanganisa amakhemikhali kwama-athomu akha ifilimu.

2. Ukufudumeza ukuhwamuka

(1) Ukumelana nokuhwamuka kokushisa

I-Resistance heat evaporation iyindlela yokufudumeza elula nevame ukusetshenziswa kakhulu, ngokuvamile esebenza ezintweni zokunameka ezinephuzu elincibilikayo elingaphansi kuka-1500 ℃, izinsimbi ezincibilika kakhulu ocingweni noma ekubunjweni kweshidi (W, Mo, Ti, Ta, boron nitride, njll.) ngokuvamile zenziwa zibe isimo esifanelekile somthombo wokuhwamuka, olayishwe ngezinto ezihwamukayo ku-heatment yamanje, ngokusebenzisa i-substrate yamanje yokuhwamuka. impahla Plating, isimo umthombo ukuhwamuka ikakhulukazi kuhlanganisa multi-strand Kuvunguza, U-shaped, sine wave, ipuleti elincanyana, isikebhe, Isigaxa ubhasikidi, njll Ngesikhathi esifanayo, indlela idinga ukuthi umthombo ukuhwamuka impahla ibe iphuzu eliphezulu ukuncibilika, saturation low umusi ingcindezi, ezinzile izakhiwo zamakhemikhali, ungabi ukusabela kwamakhemikhali nge impahla enamathela at izinga lokushisa eliphezulu, uguquko oluphakeme lokushisa, ukuhwamuka okuhle ukuhwamuka, ukwamukela ukuhwamuka kwamandla. umthombo wokuwenza ushise futhi uhwamulise ifilimu ngokufudumeza okuqondile, noma ufake ifilimu ku-crucible eyenziwe ngegraphite kanye nama-oxide ensimbi athile amelana nokushisa okuphezulu (njenge-A202, B0) nezinye izinto zokushisisa okungaqondile ukuze zihwamuke.

I-Resistance heat evaporation coating inemikhawulo: izinsimbi eziphikisayo zinengcindezi ephansi ye-vapor, okunzima ukwenza ifilimu encane; ezinye izakhi kulula ukwenza i-alloy ngocingo lokushisa; akulula ukuthola ukwakheka okufanayo kwefilimu ye-alloy. Ngenxa yesakhiwo esilula, intengo ephansi kanye nokusebenza okulula kokumelana nokushisa ukuhwamuka kwendlela, kuwukusetshenziswa okuvamile kakhulu kwendlela yokuhwamuka.

(2) Ukuhwamuka kokushisisa kwe-electron beam

Ukuhwamuka kwe-electron beam kuyindlela yokuhwamuka kwento enamathelayo ngokuyiqhumisa ngenduku ye-electron enamandla amakhulu ngokuyibeka ku-crucible yethusi epholile ngamanzi. Umthombo wokuhwamuka uqukethe umthombo wokuphuma kwama-electron, umthombo wamandla asheshisa i-electron, i-crucible (imvamisa i-copper crucible) , ikhoyili yamagnetic field, nesethi yamanzi okupholisa, njll. Kule divayisi, okokusebenza okushisayo kufakwa ku-crucible epholiswe ngamanzi, futhi i-electron beam ibhomuza ibhomu kuphela, kuyilapho ingxenye encane kakhulu yomphumela opholile esele iqhuma. i-crucible, engathathwa njengengxenye eqhumayo ye-crucible. Ngakho-ke, indlela yokushisisa i-electron beam ukuze ihwamuke ingagwema ukungcola phakathi kwezinto zokumboza nezinto zomthombo wokuhwamuka.

Isakhiwo somthombo we-electron beam evaporation singahlukaniswa ngezinhlobo ezintathu: izibhamu eziqondile (izibhamu ze-Boules), izibhamu eziyindandatho (eziphambukiswe ngogesi) kanye nezibhamu ze-e (eziphambukiswe ngozibuthe). Isitsha esisodwa noma ngaphezulu singafakwa endaweni yokuhwamuka, engahwamuka futhi ifake izinto eziningi ezahlukene ngesikhathi esisodwa noma ngokuhlukana.

Imithombo ye-electronic beam evaporation inezinzuzo ezilandelayo.

①Ukuminyana okuphezulu kwebhimu yomthombo wokuhwamuka kwe-electron beam bombardment kungathola ukuminyana kwamandla okukhulu kakhulu kunomthombo wokushisisa ukumelana, ongahwamulisa izinto zamaphuzu ancibilikayo aphezulu, njenge-W, Mo, Al2O3, njll.

②Into enamathelayo ifakwa ku-crucible yethusi epholiswe ngamanzi, engagwema ukuhwamuka komthombo wokuhwamuka, kanye nokusabela phakathi kwakho.

③Ukushisa kungangezwa ngqo endaweni enamathelayo, okwenza ukusebenza kahle kokushisa kuphakame kanye nokulahlekelwa ukuqhutshwa kokushisa kanye nemisebe yokushisa ibephansi.

Ububi bendlela yokuhwamuka kokushisisa kwe-electron beam ukuthi ama-electron ayinhloko asuka kusibhamu se-electron kanye nama-electron esibili asuka endaweni enamathelayo azokhipha ama-athomu ahwamukayo nama-molecule egesi asele, okuzothinta ikhwalithi yefilimu ngezinye izikhathi.

(3) I-high frequency induction heat evaporation

I-high-frequency induction heat evaporation iwukubeka i-crucible enento enamathelayo phakathi nendawo yekhoyili evunguzayo ye-high-frequency, ukuze okokunamathelayo kukhiqize umphumela oqinile we-eddy current kanye ne-hysteresis ngaphansi kokufakwa kwenkundla ye-electromagnetic high-frequency, okwenza ungqimba lwefilimu lushise luze luhwamuke futhi luhwamuke. Umthombo wokuhwamuka ngokuvamile uqukethe ikhoyili yefrikhwensi ephezulu epholiswe ngamanzi kanye ne-graphite noma i-ceramic (i-magnesium oxide, i-aluminium oxide, i-boron oxide, njll.) Ukunikezwa kwamandla okuvama okuphezulu kusebenzisa imvamisa yezinkulungwane eziyishumi kuya kumakhulu amaningana ezinkulungwane ze-Hz, amandla okufaka angama-kilowatts amaningana kuya kwamakhulu amaningana, ivolumu encane yento ye-membrane, iyanda imvamisa yokungeniswa. Imvamisa yekhoyili ye-induction ngokuvamile yenziwa ngeshubhu yethusi epholile ngamanzi.

Ububi bendlela ye-high-frequency induction heat evaporation ukuthi akulula ukulungisa amandla okufakwayo, inezinzuzo ezilandelayo.

①Izinga eliphezulu lokuhwamuka

②Izinga lokushisa lomthombo wokuhwamuka liyafana futhi lizinzile, ngakho-ke akulula ukukhiqiza isenzakalo sokuchaphaza kwamaconsi anamathelayo, futhi lingagwema isenzakalo samaphinifa efilimu efakiwe.

③Umthombo wokuhwamuka ulayishwa kanye, futhi izinga lokushisa lilula futhi kulula ukulilawula.

Isikhathi sokuthumela: Oct-28-2022