INCAZELO YOMKHIQIZO

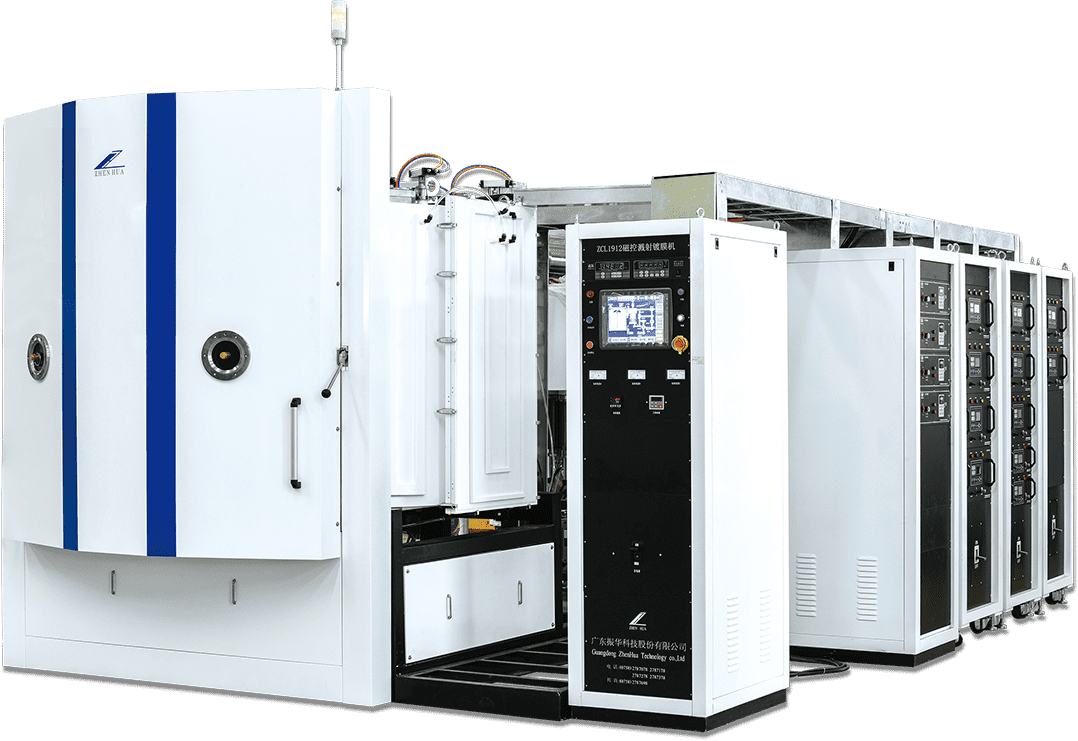

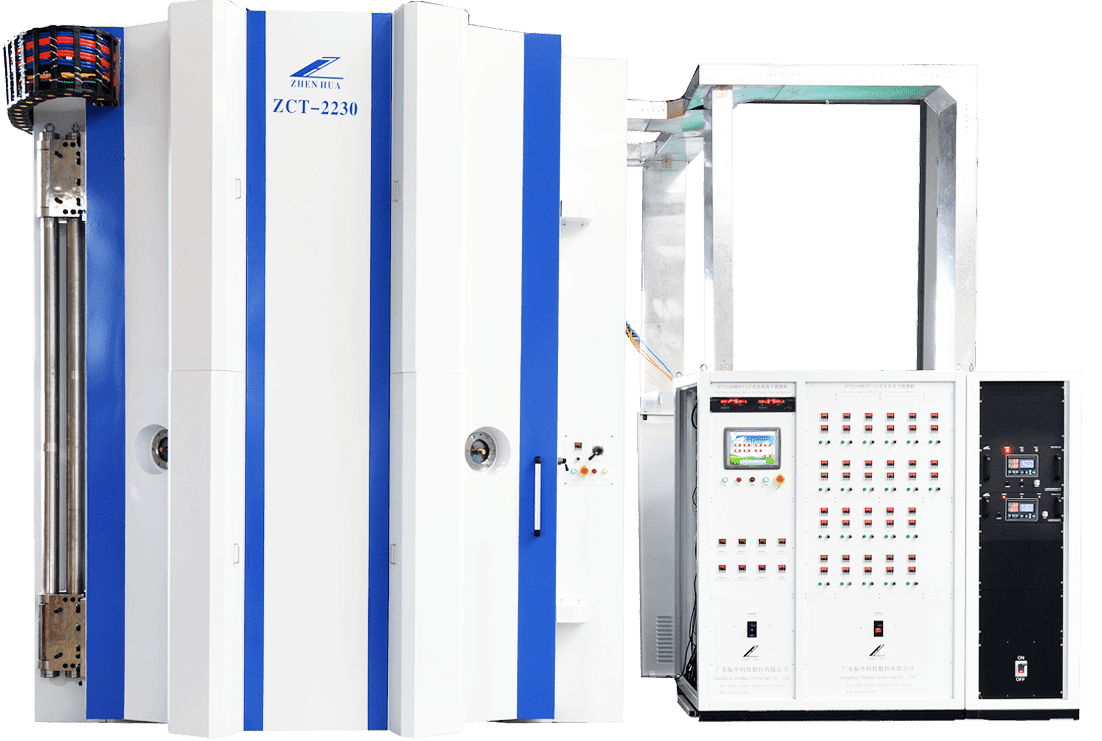

Imishini ihlanganisa ubuchwepheshe be-magnetron sputtering kanye ne-ion coating, ihlinzeka ngesixazululo sokuthuthukisa ukungaguquguquki kombala, izinga lokubeka kanye nokuzinza kokubunjwa okuhlanganisiwe. Ngokwezidingo ezahlukene zomkhiqizo, kungakhethwa uhlelo lokushisa, uhlelo lokuchema, uhlelo lwe-ionization namanye amadivaysi. Ukusatshalaliswa kwendawo okuhlosiwe kungalungiswa kalula, futhi ukufana kwefilimu kuphakeme. Ngezinhloso ezihlukene, amafilimu ayinhlanganisela asebenza kangcono angambozwa. Ukugqoka okulungiselelwe imishini kunezinzuzo zokunamathela okuqinile nokuqina okuphezulu, okungathuthukisa ngokuphumelelayo ukumelana ne-salt spray, ukumelana nokugqoka kanye nobulukhuni bobuso bomkhiqizo, futhi kuhlangabezane nezidingo zokulungiswa kokusebenza okuphezulu kokusebenza.

Izinto zokusebenza zingasetshenziswa ensimbi engagqwali, izingxenye ze-electroplated hardware / plastic, glass, ceramics nezinye izinto. Ingakwazi ukulungisa i-TiN / TiCN / TiC / TiO2 / TiAlN / CrN / ZrN / CrC namanye amafilimu ensimbi. Ingakwazi ukufeza umnyama omnyama, igolide lesithando somlilo, igolide elikhazimulayo, igolide lokulingisa, igolide le-zirconium, isafire eluhlaza okwesibhakabhaka, isiliva elikhanyayo neminye imibala.

Lolu chungechunge lwemishini lusetshenziselwa ikakhulukazi i-hardware yemikhiqizo ye-elekthronikhi, amawashi namawashi asezingeni eliphezulu, ubucwebe bezinga eliphezulu, i-hardware yezimpahla zohlobo lokunethezeka, njll.

Amamodeli ongawakhetha

| I-ZCL0608 | I-ZCL1009 | I-ZCL1112 | I-ZCL1312 |

| Φ600*H800(mm) | φ1000*H900(mm) | φ1100*H1250(mm) | φ1300*H1250(mm) |

| I-ZCL1612 | I-ZCL1912 | I-ZCL1914 | I-ZCL1422 |

| φ1600*H1250(mm) | φ1900*H1250(mm) | φ1900*H1400(mm) | φ1400*H2200(mm) |